Chemically crosslinked ultrahigh molecular weight polyethylene for artificial human joints

a technology of polyethylene and high molecular weight, applied in the field of polymers, can solve the problems of adhesive wear, many microscopic wear particles into the surrounding tissues, long-term failure of such prostheses, etc., and achieve the effects of reducing the crystallinity of the polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Experimental Details

[0060]Commercial-grade UHMW polyethylene GUR 415 (from Hoechst-Celanese Corporation, League City, Tex.), with a weight average molecular weight of 6×106, was used as received. The peroxide used was 2,5-dimethyl-2,5-bis(tert-butylperoxy)-3-hexyne (Lupersol 130, Atochem Inc., Philadelphia, Pa.). The reason for choosing Lupersol 130 was its long half-life at elevated temperature. The peroxide will decompose slowly, and the resultant free radicals can diffuse in the specimen to form a homogeneous network at elevated temperatures.

[0061]Mixing of the UHMW polyethylene and the peroxide was accomplished by dispersing polyethylene powder in an acetone solution of the peroxide and subsequently evaporating the solvent {de Boer, J., et al., J. Polym. Sci., Polym. Phys. Ed., 14:187 (1976); de Boer, J. & Pennings, A. J., Makromol. Chem, Rapid Commun., 2:749 (1981) and de Boer, J. & Pennings, A. J., Polymer, 23:1944 (1982)}. The mixed powder (22 g) was poured into the mold cavi...

example 2

Materials and Methods

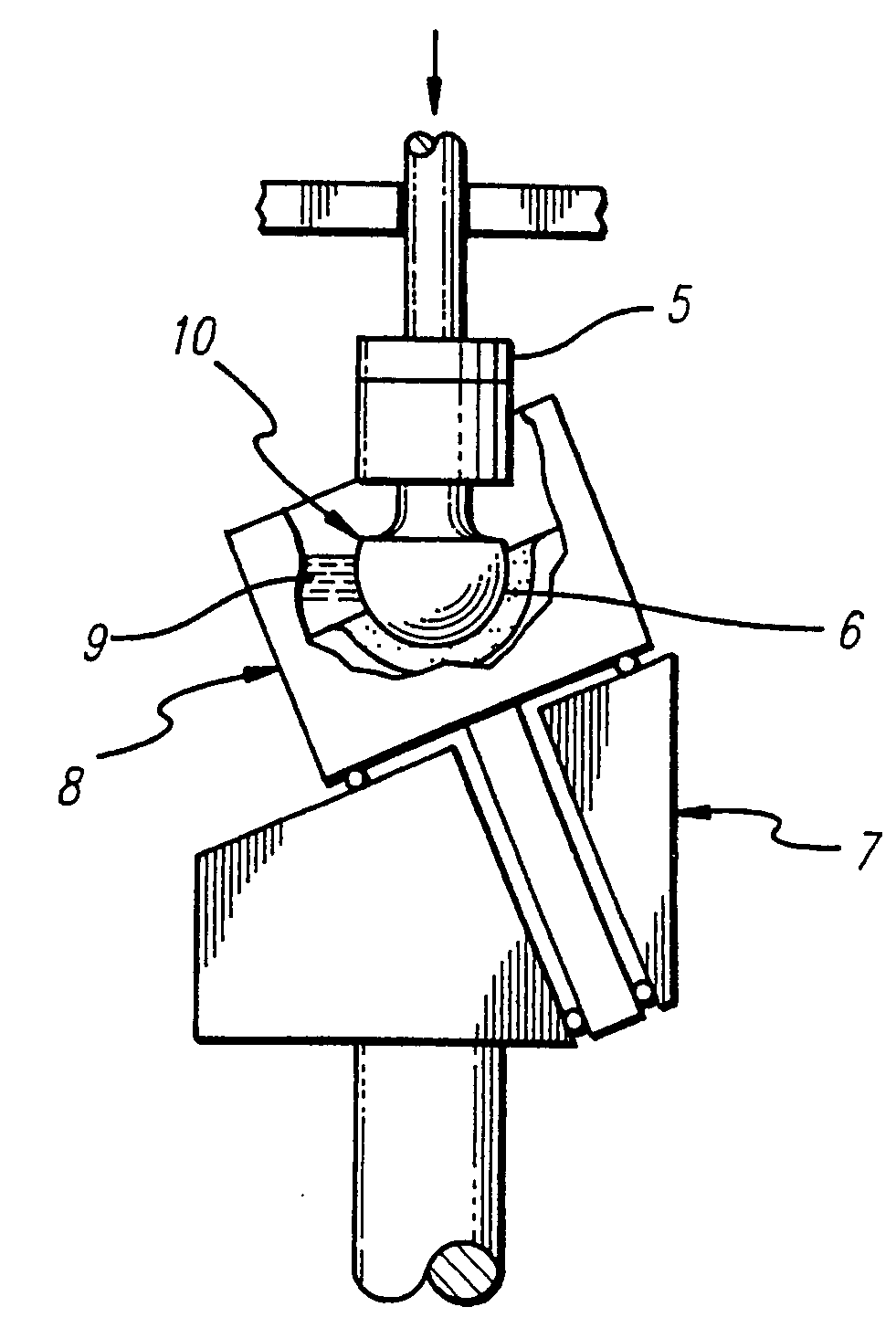

[0075]In this example, the wear resistance of the polyethylenes treated (modified) and untreated (unmodified) with peroxide in EXAMPLE 2 were tested. The control (unmodified) and modified polyethylenes were compression molded directly into the form of acetabular cups. These were then exposed to an average of approximately 3.4 Mrad of gamma radiation (SteriGenics International, Tustin, Calif.), to simulate the condition of cups that would be used in patients. Due to different amounts of post-molding shrinkage, the internal surface of each cup was machined to provide nearly identical internal diameters and ball-to-cup clearances among the control and modified cups (FIG. 3). As shown in FIG. 3B, the cup's outer radius 1 is 24.5 mm, its inner radius 2 is 16.1 mm, its height 3 is 29.8 mm, and its diameter 4 is 49.0 mm

[0076]The cups were pre-soaked in distilled water for three weeks prior to the wear test to minimize fluid absorption during the wear test. The wear cup...

example 3

[0081]During the wear test in the simulator described in EXAMPLE 2, it was discovered that the acetabular cups shrunk at simulated human body temperature. In order to stabilize the shrinkage, in this experiment (unrelated to EXAMPLE 2), the cups were annealed at 100° C. in a vacuum oven for 2 hours. After annealing, the total shrinkage in diameter for uncrosslinked and crosslinked cups was approximately 1% and 2%, respectively. The degrees of crystallinity of the annealed cups were determined by DSC. The degree of crystallinity of the uncrosslinked polymer was unchanged, whereas that of the crosslinked polymer was increased by approximately 1%. To test for further shrinkage, the cups were again put in the vacuum oven at 80° C. for two hours, and no further shrinkage was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of crystallinity | aaaaa | aaaaa |

| degree of crystallinity | aaaaa | aaaaa |

| degree of crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com