Cartridge for Viscous Fluid Materials

a fluid material and viscous technology, applied in the field of carts, can solve the problems of wall air permeability, imperfect outside air barrier properties, and penetration of outside air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

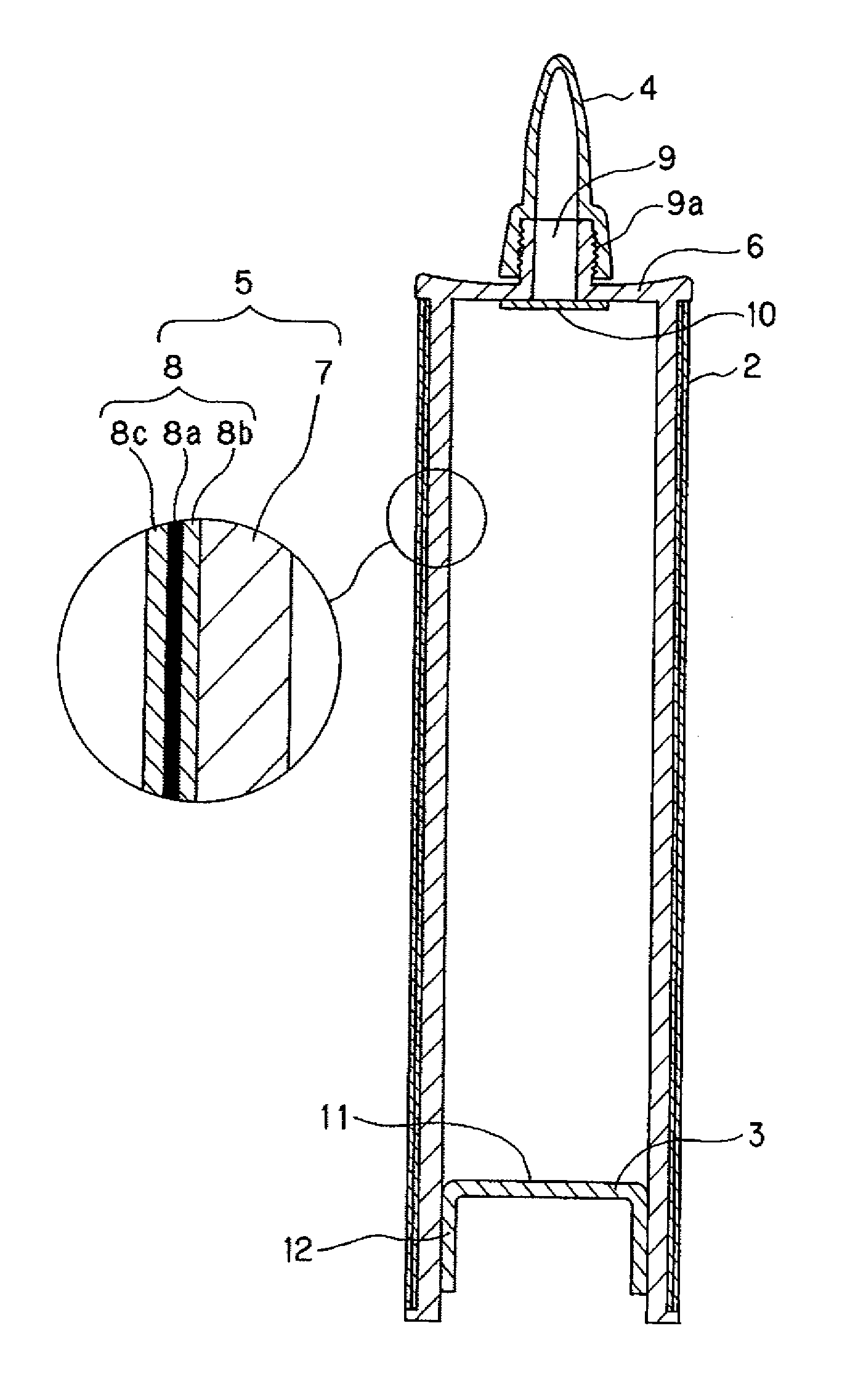

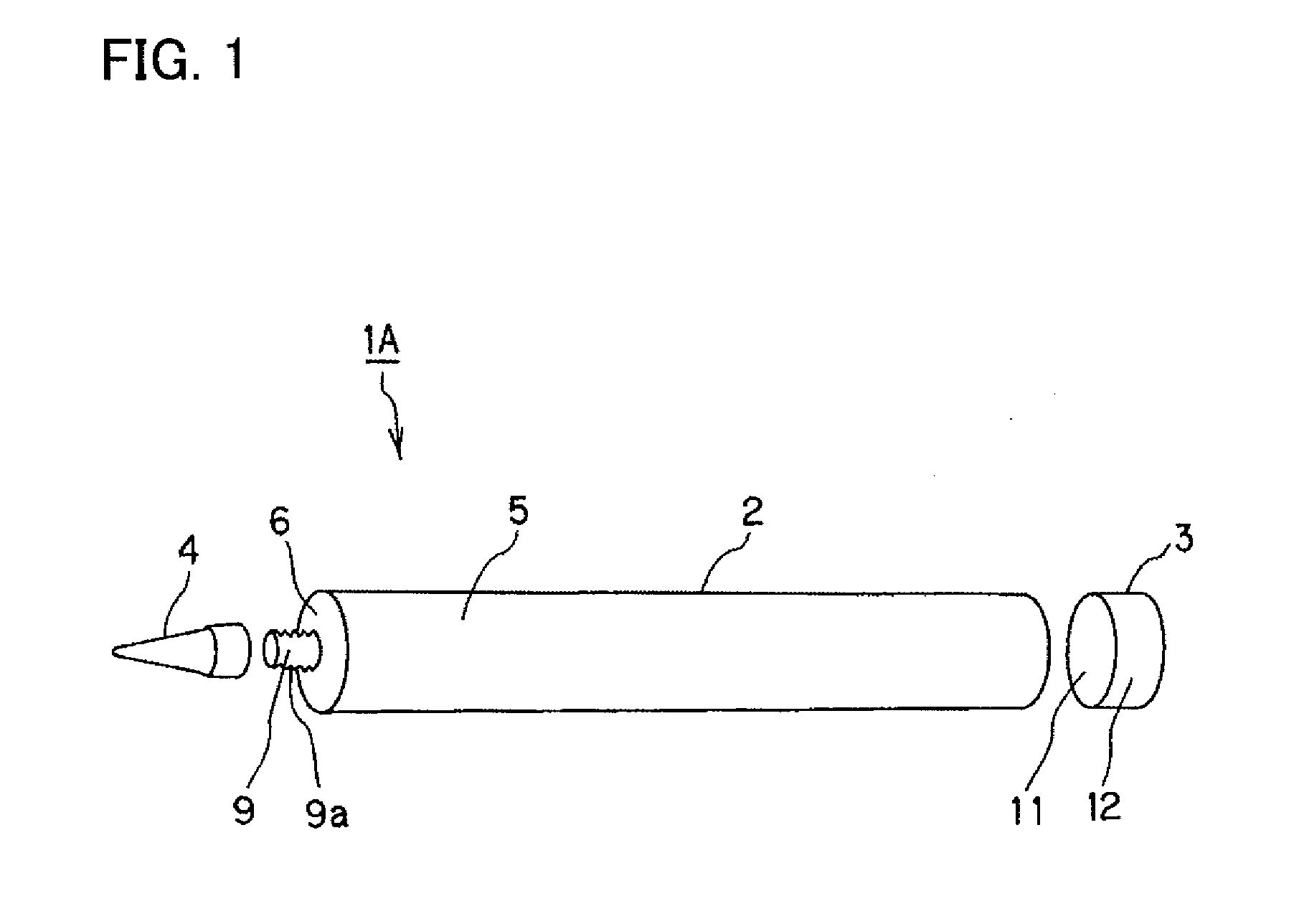

[0058]A cartridge body A having a cylindrical barrel portion provided with a gas barrier layer 8 on its exterior periphery, such as the one shown in FIG. 1 and FIG. 2, was fabricated by insert injection molding using polyethylene resin as the injection molding resin and a composite film having a layered structured obtained by laminating a PE layer, AL foil, a PET layer, and an OPP layer as an insert film for a gas barrier layer.

[0059]The resultant cartridge body 1A has a shape, in which one end of the cylindrical barrel portion is covered with a lid portion 6 provided with a cylindrical opening portion (discharge portion) in the center thereof, with the body having an internal diameter of 48 mm, a total inner length of 213 mm, and a volume of approximately 381 mm3. Its cross-sectional structure is a layered structure, in which there is a plastic layer 7 made entirely of high-density polyethylene resin, the wall thickness of the cylindrical barrel portion is 1.15 mm, and a gas barrie...

example 2

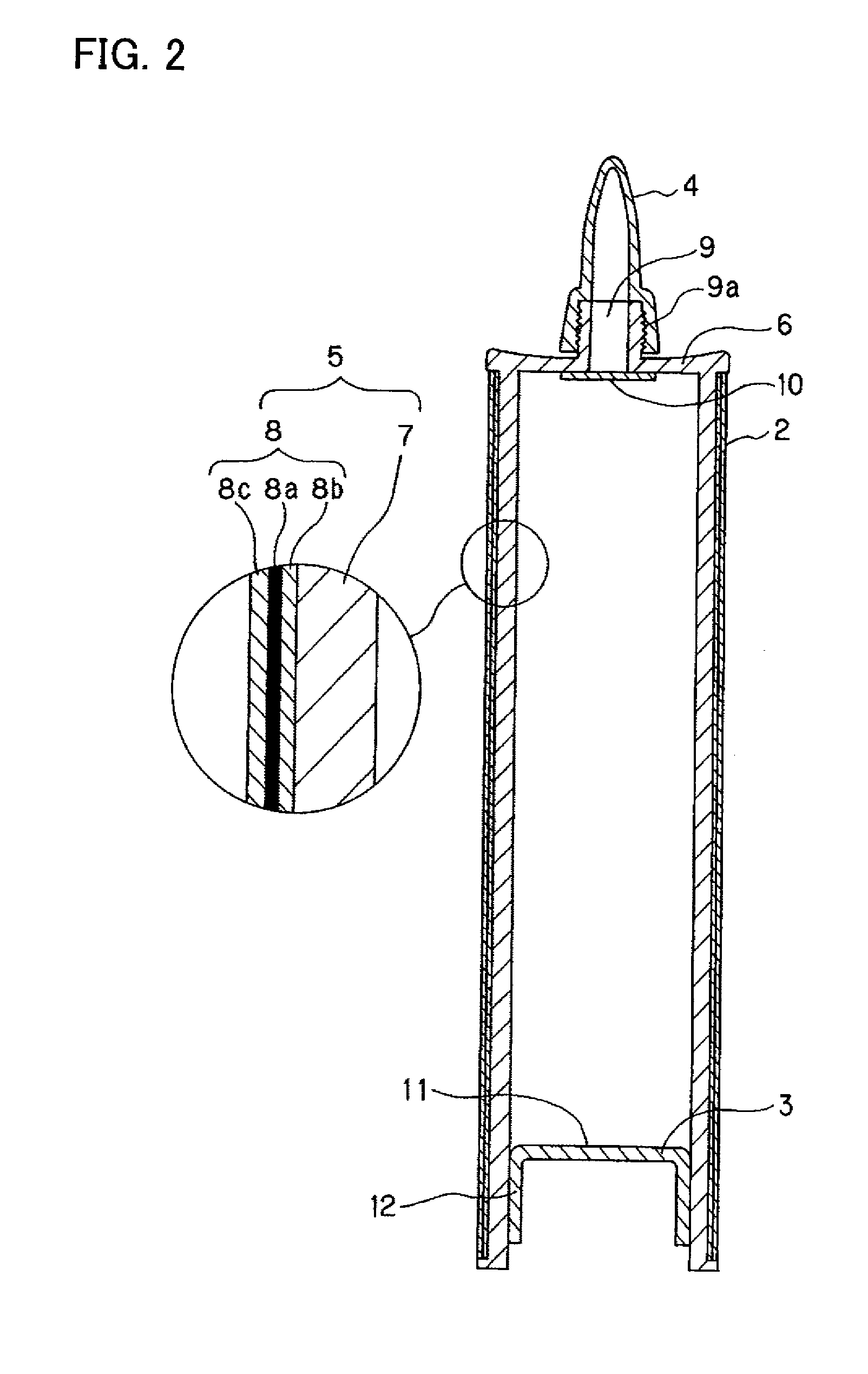

[0062]A cartridge body B having a cylindrical barrel portion provided with a gas barrier layer on the interior periphery thereof, such as the one shown in FIG. 1 and FIG. 3, was fabricated by insert injection molding using the same injection molding resin and composite film as in Example 1.

[0063]The shape and dimensions of the resultant cartridge body B were identical to those of Example 1. Its cross-sectional structure, however, was a layered structure, wherein a gas barrier layer made up of a PE bonding layer, an AL foil layer, a PET layer, and an innermost OPP layer was provided on the interior periphery of the cylindrical barrel portion.

[0064]In the same manner as in Example 1, cartridge body B had a seal film 10 fused to the lid portion 6, a threadedly engaged nozzle 4, and a mixture of polybutene and microcrystalline wax (mixing ratio: 6:4) applied to the interior peripheral surface of the opening portion at the other end.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com