Ion beam apparatus having plasma sheath controller

a technology of plasma sheath controller and ion beam apparatus, which is applied in the field of plasma apparatus, can solve the problems of not being able to obtain high ion beam ion flux, and still being required for ion beam apparatus capable of increasing ion flux, and achieves high ion flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0085]FIG. 9 illustrates ion current characteristics measured in a first ion extraction grid in order to check variation of ion beams extracted by use of a plasma sheath controller, and FIG. 10 illustrates ion current characteristics measured in a specimen chamber adjacent to a grid assembly in order to check variation of ion beams extracted by use of the plasma sheath controller. Horizontal axes P of FIGS. 9 and 10 denote radio frequency (RF) power applied to an induction coil of a plasma chamber, and the unit is watt (W). Vertical axes Ic of FIGS. 9 and 10 denote measured ion current, and the unit is micro ampere (μA).

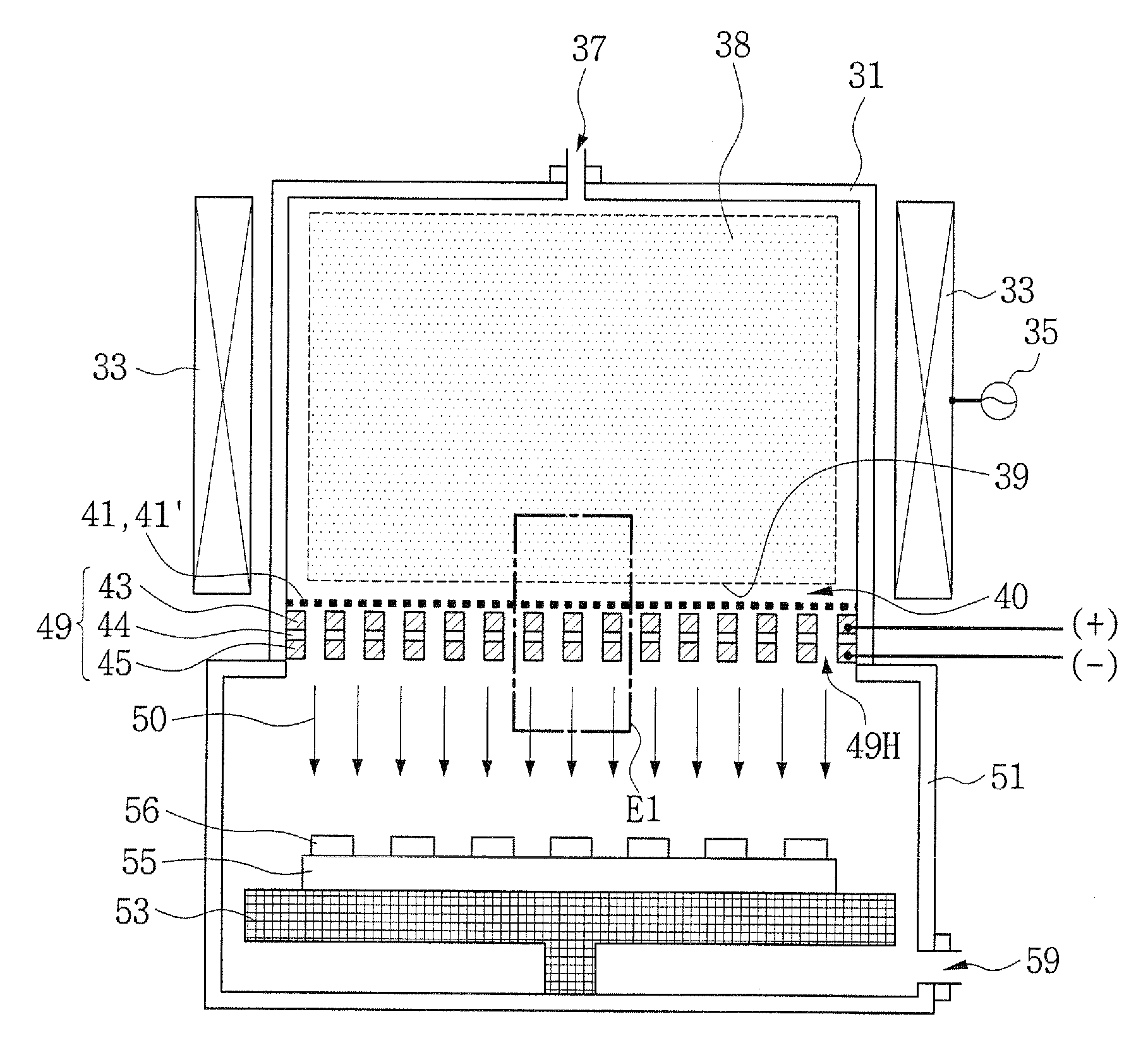

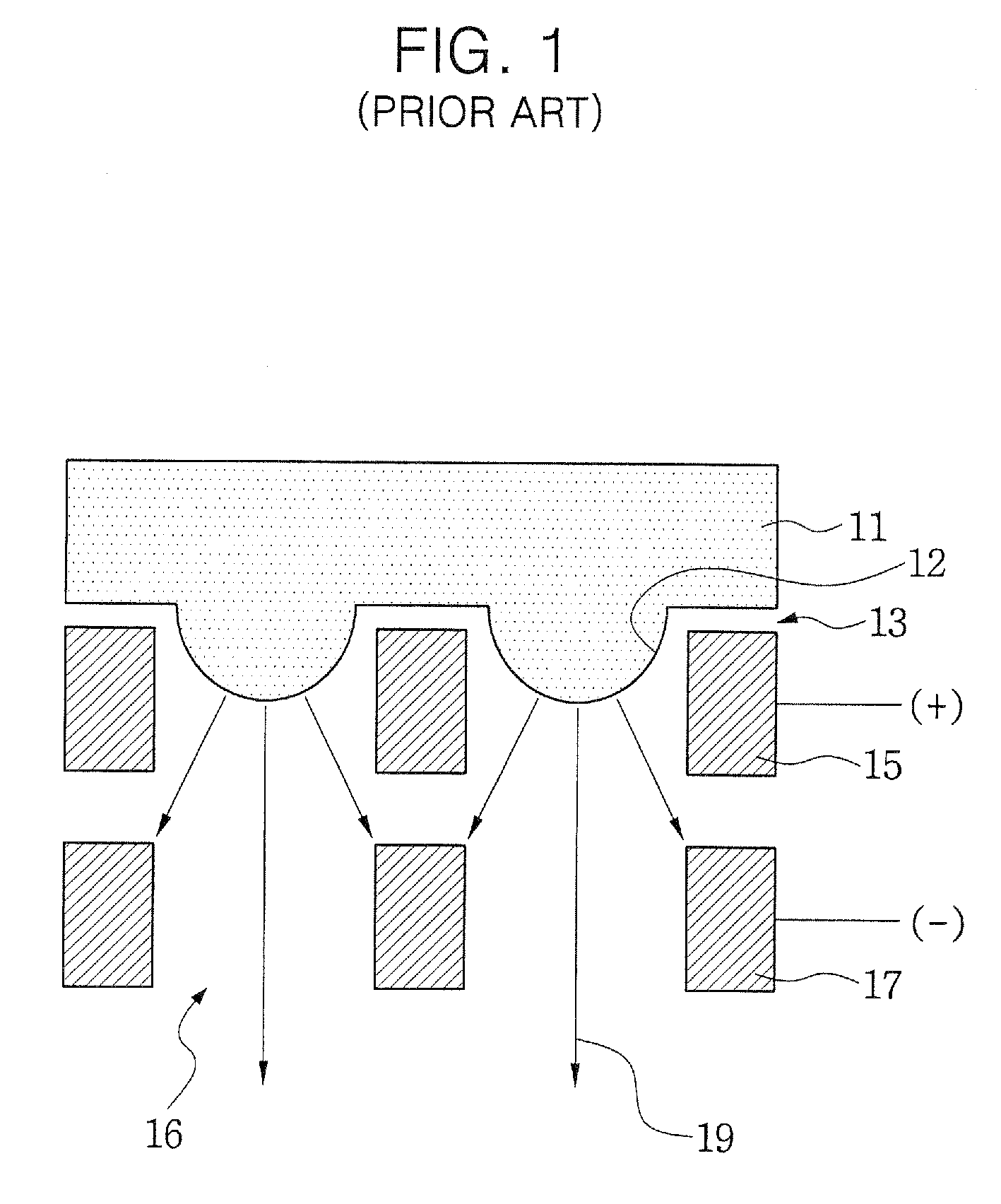

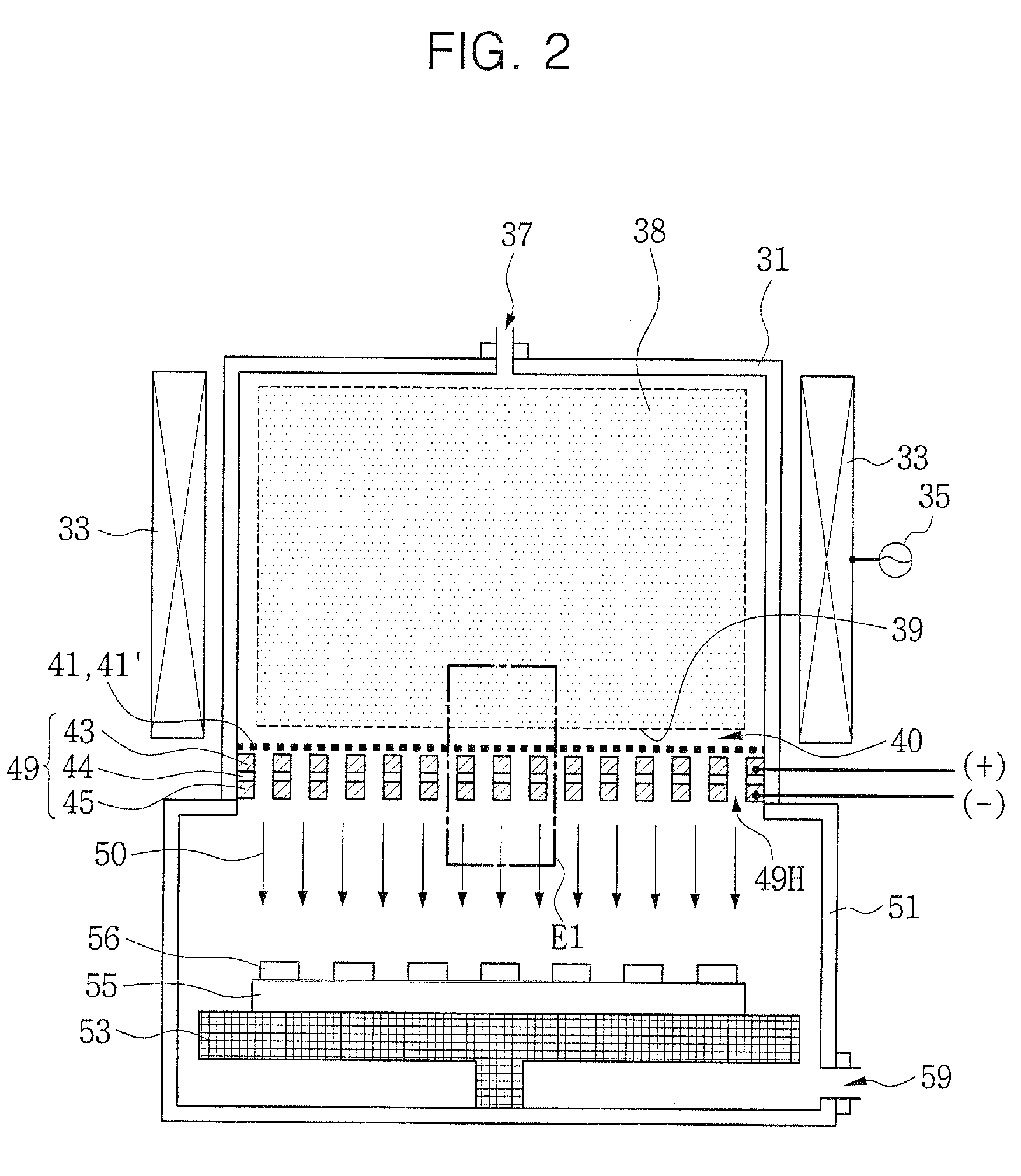

[0086]A gas used in the experiment is argon (Ar). A grid assembly including a first ion extraction grid, a second ion extraction grid, and a third ion extraction grid was used. +150V, −100V and 0V were applied to the first ion extraction grid, the second ion extraction grid, and the third ion extraction grid, respectively. The grid assembly had first ion extraction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com