A preparation method of three-frequency high-density plasma-assisted magnetron sputtering thin film

A technology for plasma and sputtering thin films, which is applied in the field of plasma-assisted magnetron sputtering thin film preparation, can solve the problems of inability to meet the performance requirements of thin films and low plasma density, and achieves high plasma density and high ion flux. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

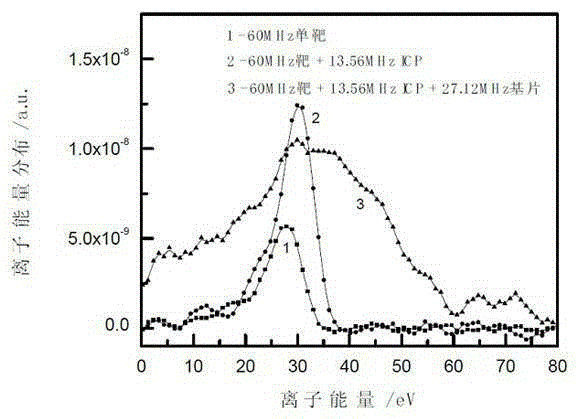

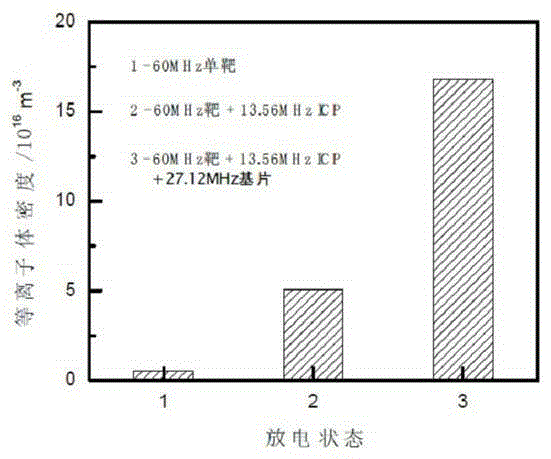

[0024] Magnetron sputtering plasma performance of embodiment one triple-frequency discharge

[0025] Adopting the high-density plasma magnetron sputtering thin film preparation method driven by triple frequency provided by the present invention can realize independent control of plasma density, ion flux and ion energy, forming high plasma density, high ion flux and Broad ion energy.

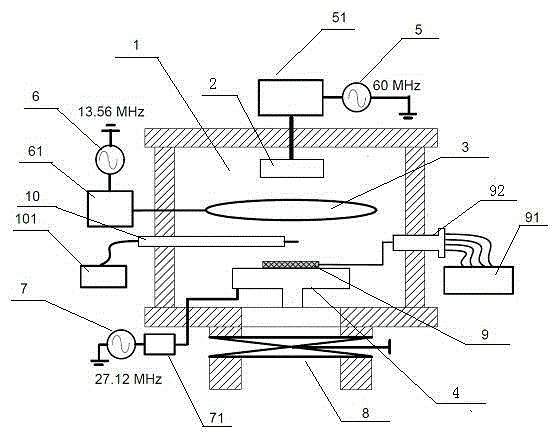

[0026] attached figure 1 Schematic diagram of the structure of the thin film device prepared for high-density plasma magnetron sputtering driven by triple frequency; according to the attached figure 1 , three-frequency driven high-density plasma magnetron sputtering device for preparing thin films includes a vacuum chamber 1, a sputtering target 2, an ICP coil 3, a substrate stage 4, a 60MHz power supply 5 connected to the target 2 and a corresponding matching regulator 51 , a 13.56MHz power supply 6 connected to the ICP coil 3 and a corresponding matching regulator 61, a 27.12MHz power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com