Preparation method and application of chlorosulfonated polyethylene-based cation exchange membrane for diffusion dialysis

A chlorosulfonated polyethylene and cation exchange membrane technology, applied in the field of membrane separation, can solve the problems of limited cation exchange membrane separation and recovery applications, single type of cation exchange membrane, strict requirements on stability and separation performance, etc. performance, good film formation, high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of chlorosulfonated polyethylene-based cation exchange membrane

[0026] Pour 4g of chlorosulfonated polyethylene rubber and 80mL of toluene solution into a 100mL three-necked flask and raise the temperature to 80°C, swell and stir until completely dissolved, add 2g of methacrylic acid and 0.006g of triacryl isocyanurate mixed liquid, Stir at 80°C, blow nitrogen for 20 minutes; add 0.02g initiator azobisisobutyronitrile dissolved in 5mL toluene solution, initiate polymerization for 5 hours, stir and cool to room temperature, add 0.2g dipentylthiuram tetrasulfide, After stirring for 20 minutes, it was poured onto a horizontal glass plate, and the solvent was naturally volatilized in a fume hood to form a film; it was hot-pressed in a vulcanizing machine at 185°C and 10 MPa for 10 minutes to obtain the final required chlorosulfonated polyethylene-based cation exchange membrane.

[0027] 2. Performance test

[0028] Chlorosulfonated polyethylene-based catio...

Embodiment 2

[0033] The preparation method and performance testing method of the film in this example are the same as those in Example 1, except that the addition amount of the crosslinking agent tripropenyl isocyanurate (TAIC) in this example is 0.01 g.

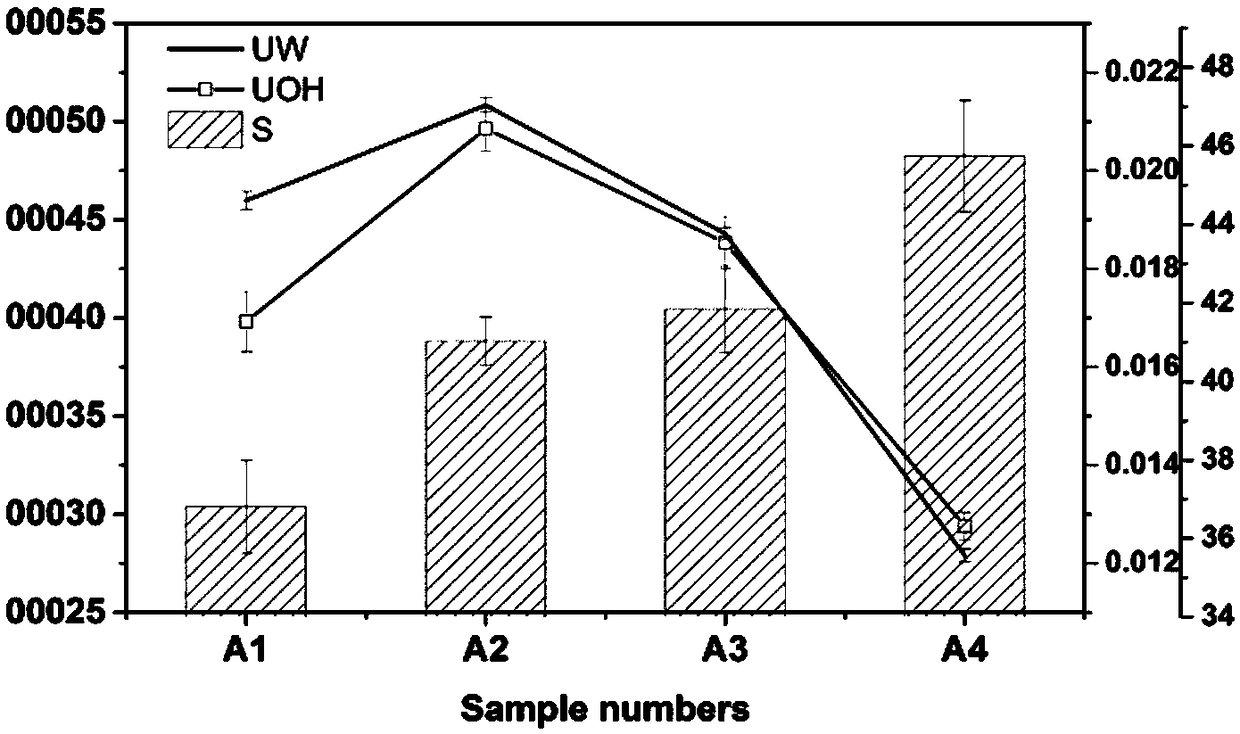

[0034] After testing, the performance parameters of the cationic membrane obtained in this embodiment are: the permeability coefficient (U OH ) is 0.0209m / h, the permeability coefficient of tungstate (U W ) is 0.000508m / h, the separation coefficient (S) is 41.0; the water content of the membrane (W R ) is 46.7%.

Embodiment 3

[0036] The preparation method and performance testing method of the film in this example are the same as those in Example 1, except that the addition amount of the crosslinking agent tripropenyl isocyanurate (TAIC) in this example is 0.014 g.

[0037] After testing, the performance parameters of the cationic membrane obtained in this embodiment are: the permeability coefficient (U OH ) is 0.0185m / h, the permeability coefficient of tungstate (U W ) is 0.000443m / h, the separation coefficient (S) is 41.8; the water content of the membrane (W R ) is 46.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com