Coplanar waveguide resonator and coplanar waveguide filter using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

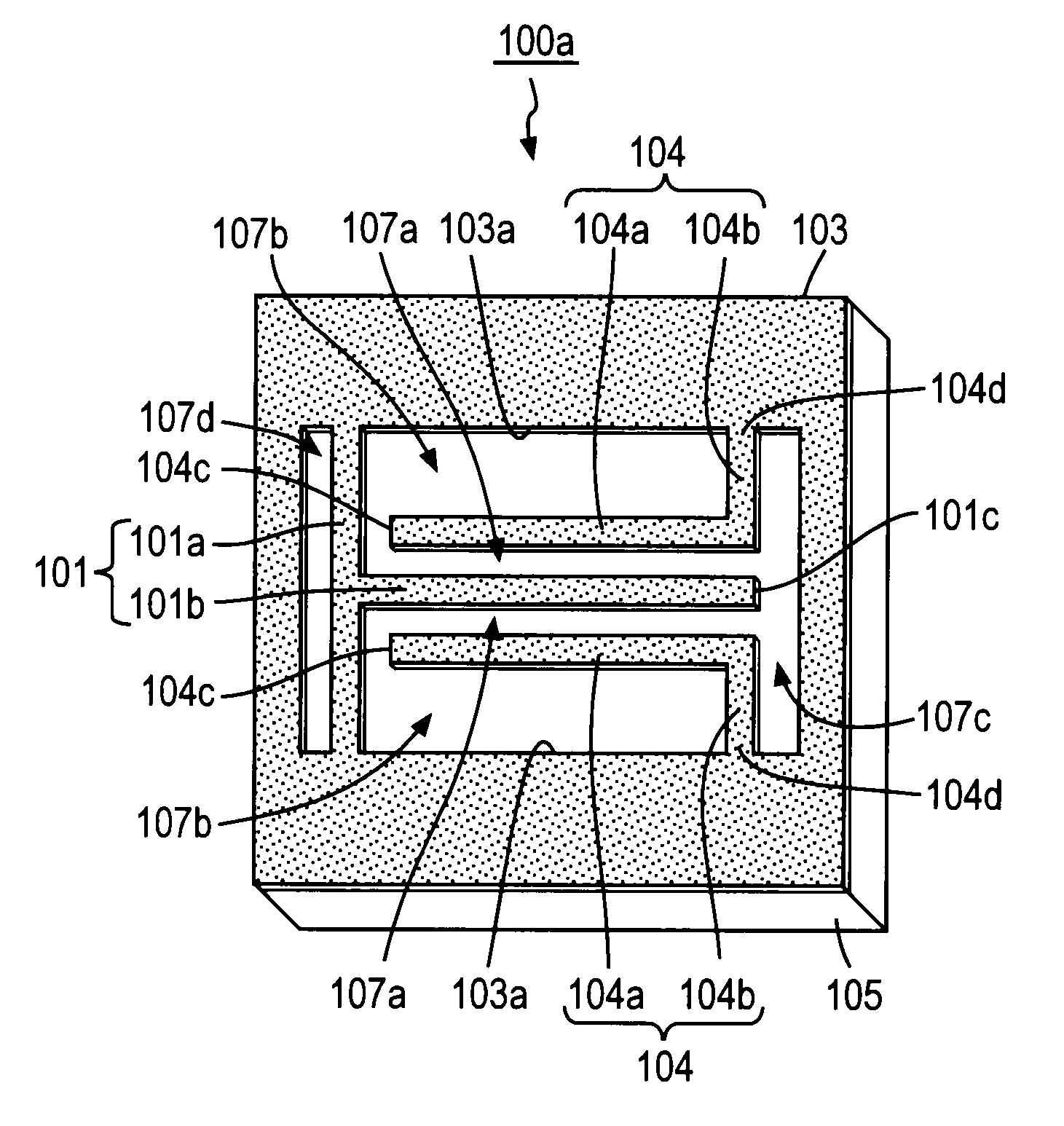

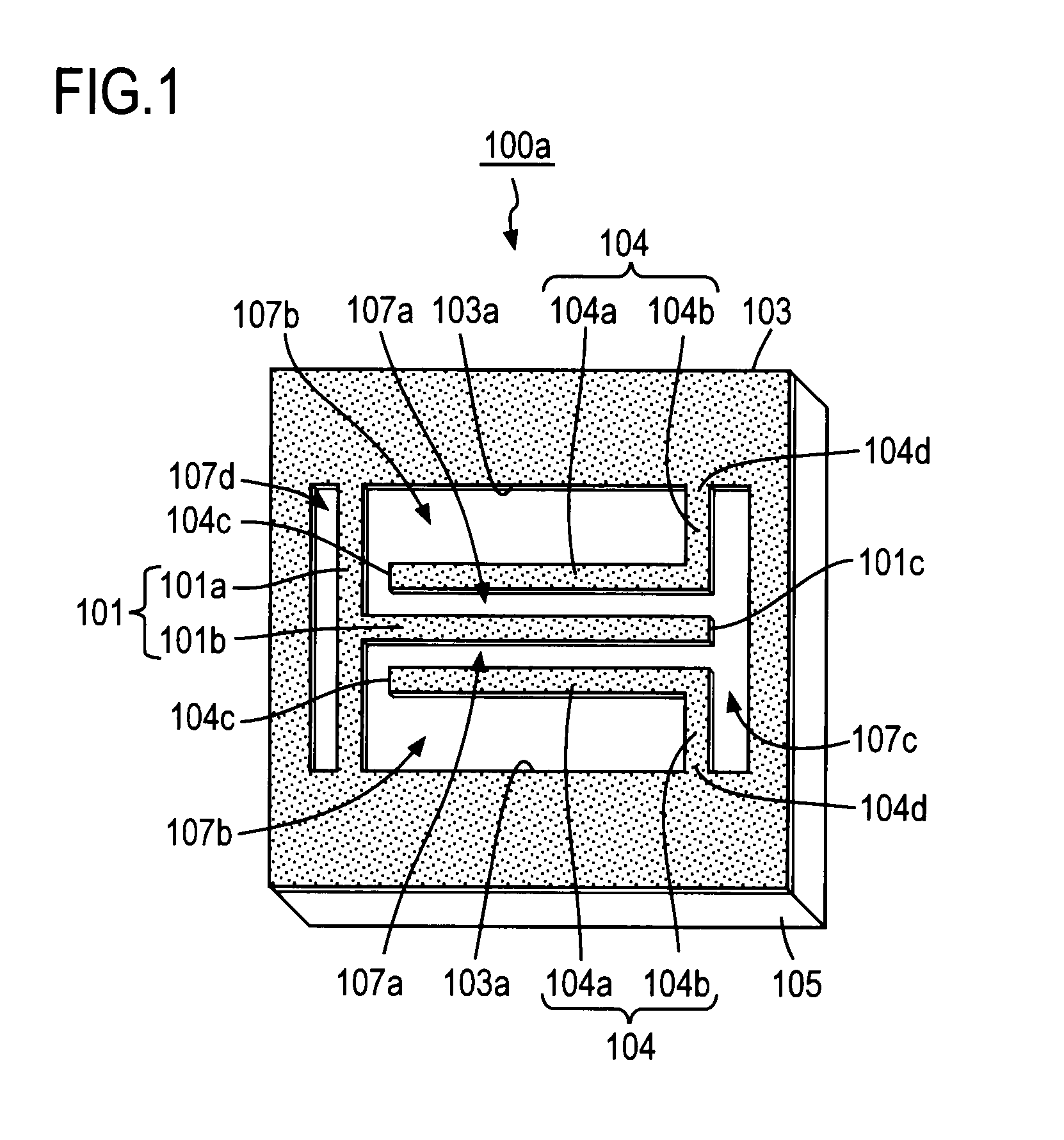

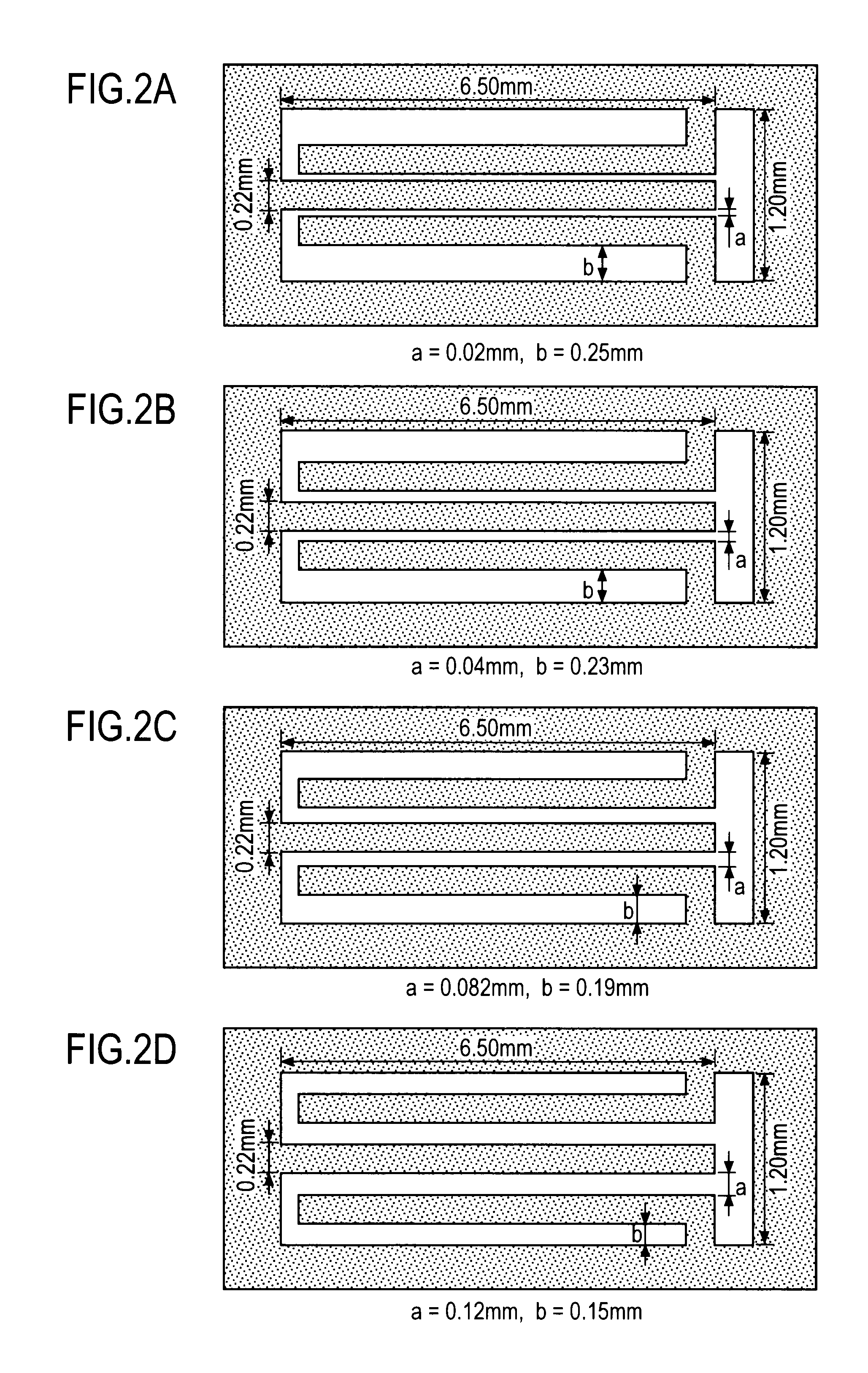

[0069]Embodiments of the present invention will be described with reference to FIGS. 1 to 26. In FIGS. 1, 2A to 2G, 4 to 8, 9A to 9I and 11 to 13, illustration of input / output terminals actually disposed on the opposite ends of the coplanar waveguide resonator shown in each drawing (the left and right ends of the coplanar waveguide resonator when each drawing is viewed straight from the front) is omitted. In all the drawings except for FIG. 1, illustration of a dielectric substrate 105 is omitted.

[0070]FIG. 1 shows a coplanar waveguide resonator according to an embodiment of the present invention. In this embodiment, the coplanar waveguide resonator is a quarter-wavelength coplanar waveguide resonator. A quarter-wavelength coplanar waveguide resonator 100a shown in FIG. 1 comprises a ground conductor 103 disposed on a surface of a dielectric substrate 105 illustrated as a rectangular shape, and a center conductor 101 and two line conductors 104 formed by patterning the ground conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com