Implantable centrifugal blood pump with hybrid magnetic bearings

a centrifugal, magnetic bearing technology, applied in the direction of positive displacement liquid engine, prosthesis, liquid fuel engine, etc., can solve the problems of mechanical work, inapplicability of rolling element bearings to blood pumps, and notorious wear and failure of rotating shaft seals, etc., to achieve low heat dissipation, low attractive force, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Reference will now be made to the drawings in which the various elements of systems and methods of this disclosure will be given numeral designations and in which the invention will be discussed so as to enable one skilled in the art to make and use the invention. It is to be understood that the following description is only exemplary of the principles of the invention as claimed, and should not be viewed as narrowing the pending claims.

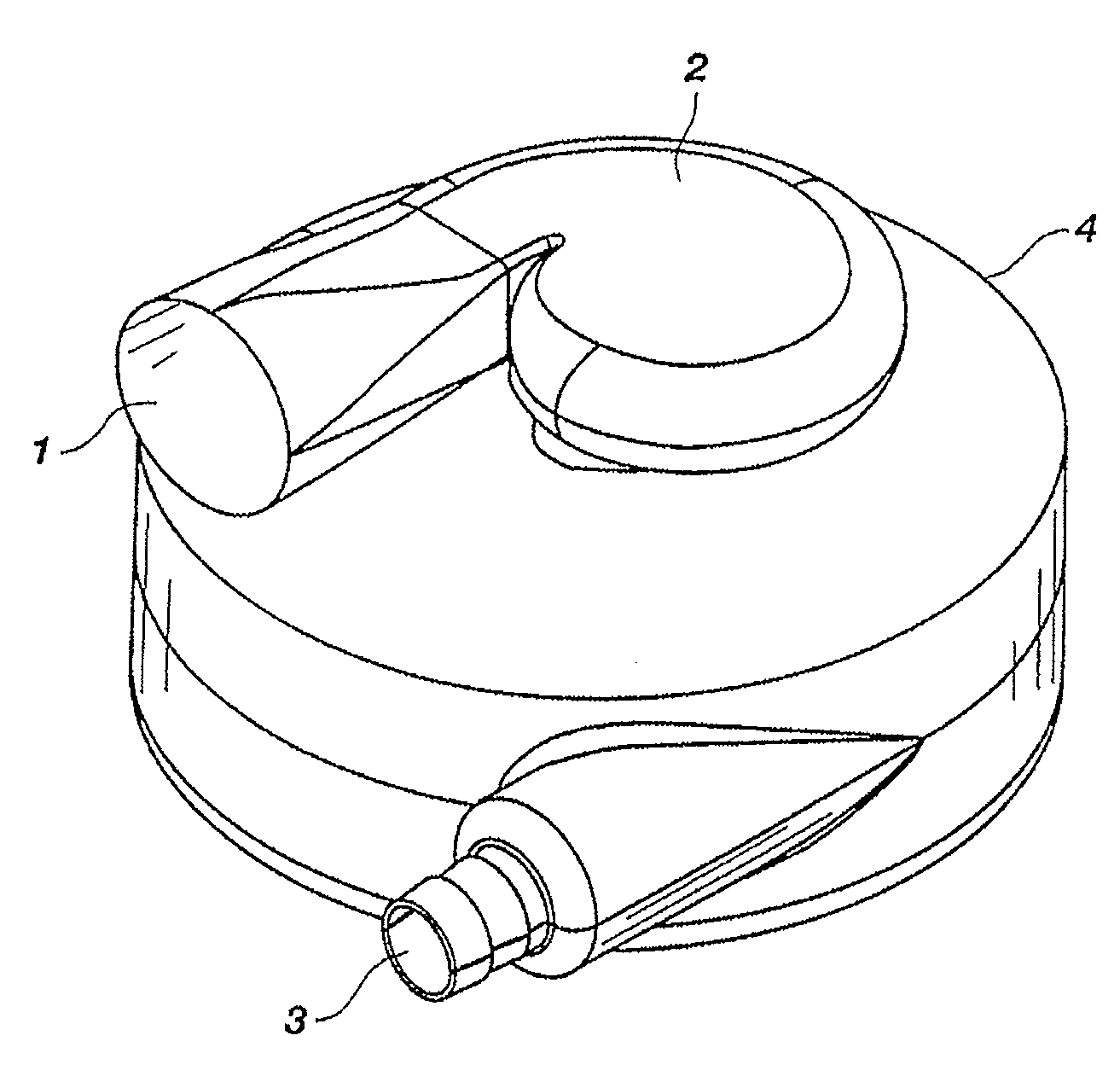

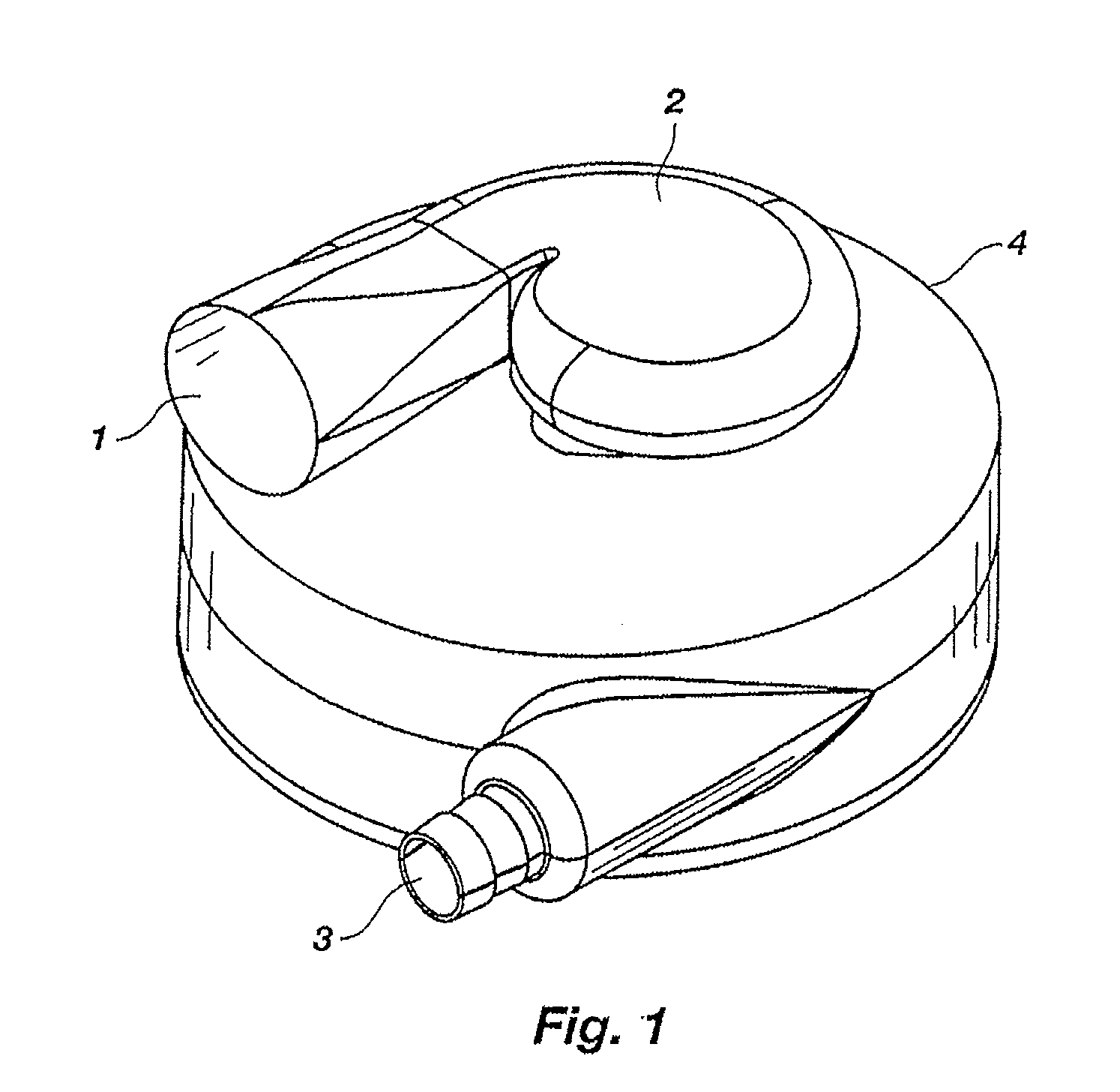

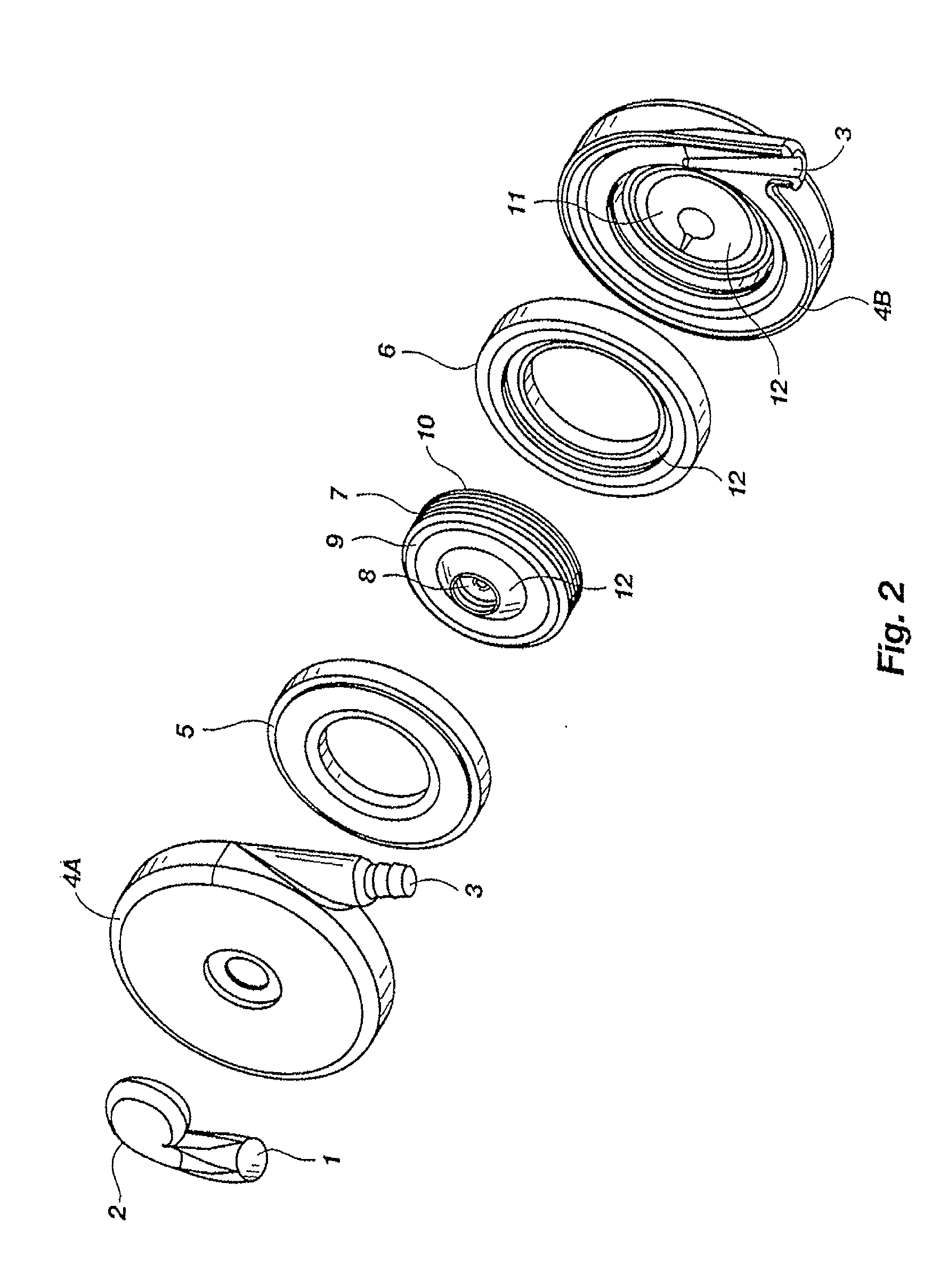

[0038]A perspective view of the assembled pump of the preferred embodiment is shown in FIG. 1. The pump generally comprises a housing 4 with an inlet 1, flow turning structure 2, and outlet 3. The flow turning structure 2 is configured to redirect incoming fluid flow through an acute angle in a gentle, low thermal manner using a compact structure. The turning structure is configured such that flow swirls around the inlet in a logarithmic spiral configuration, equalizing the flow rate and pressure entering the inlet. Additionally, this spiral in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com