Magnetic Convection Heat Circulation Pump

a heat circulation pump and magnetic convection technology, applied in the direction of lighting and heating apparatus, machines using electric/magnetic effects, refrigerating machines, etc., can solve the problems of not being suitable for cooling an object, devices having external heating means only have limited uses, and not being put into commercial use, etc., to reduce the magnitude of saturation magnetization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

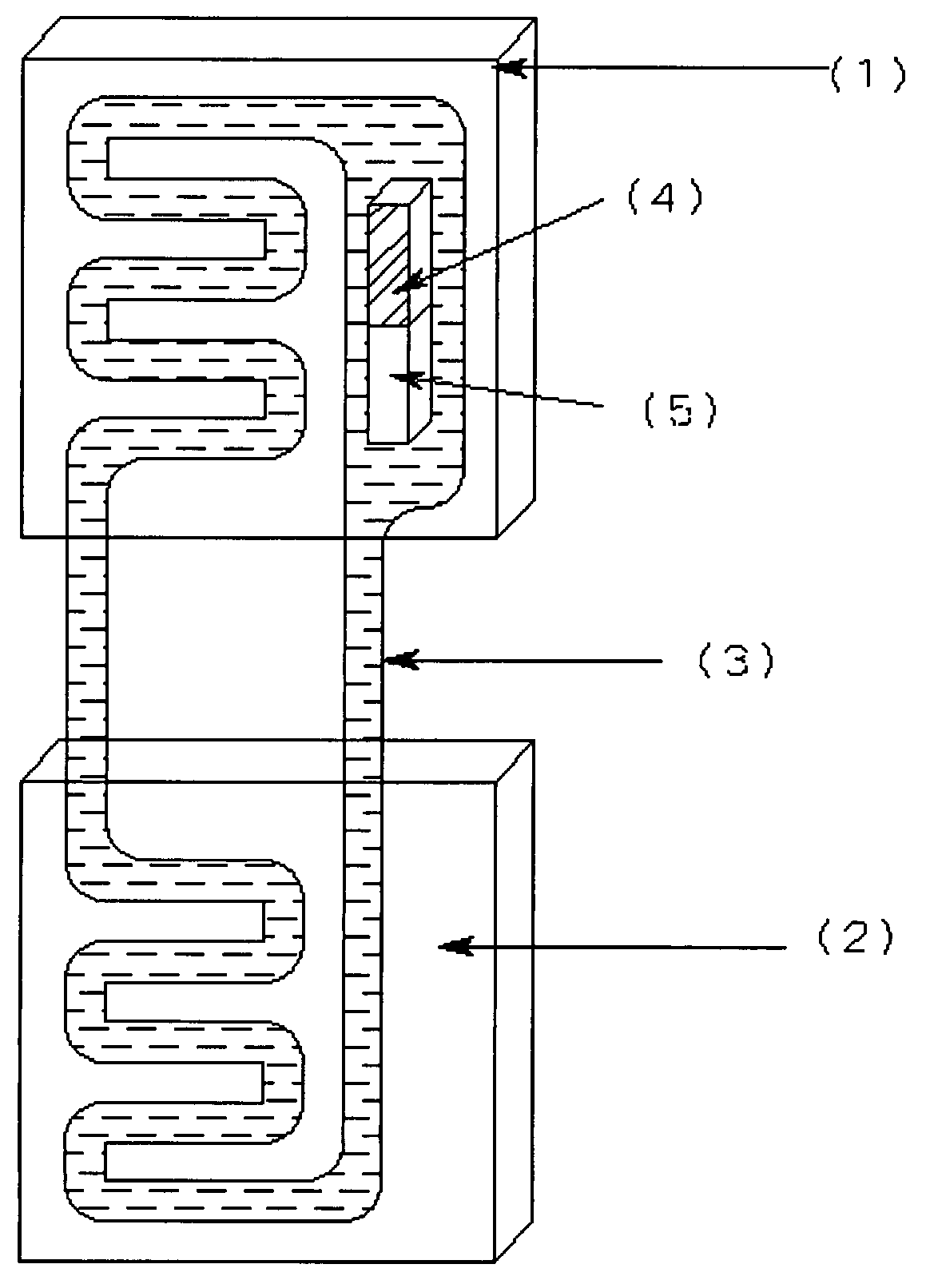

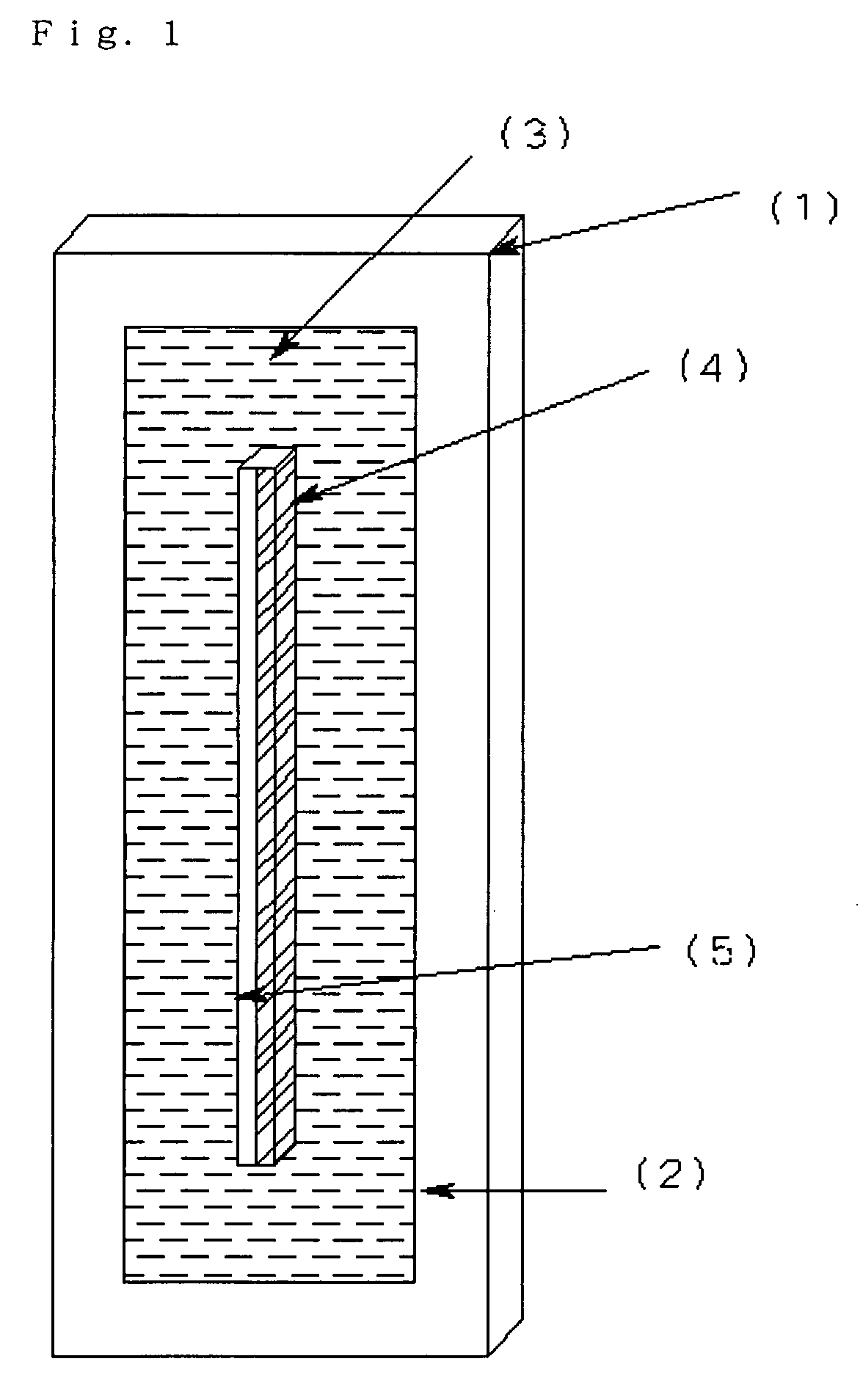

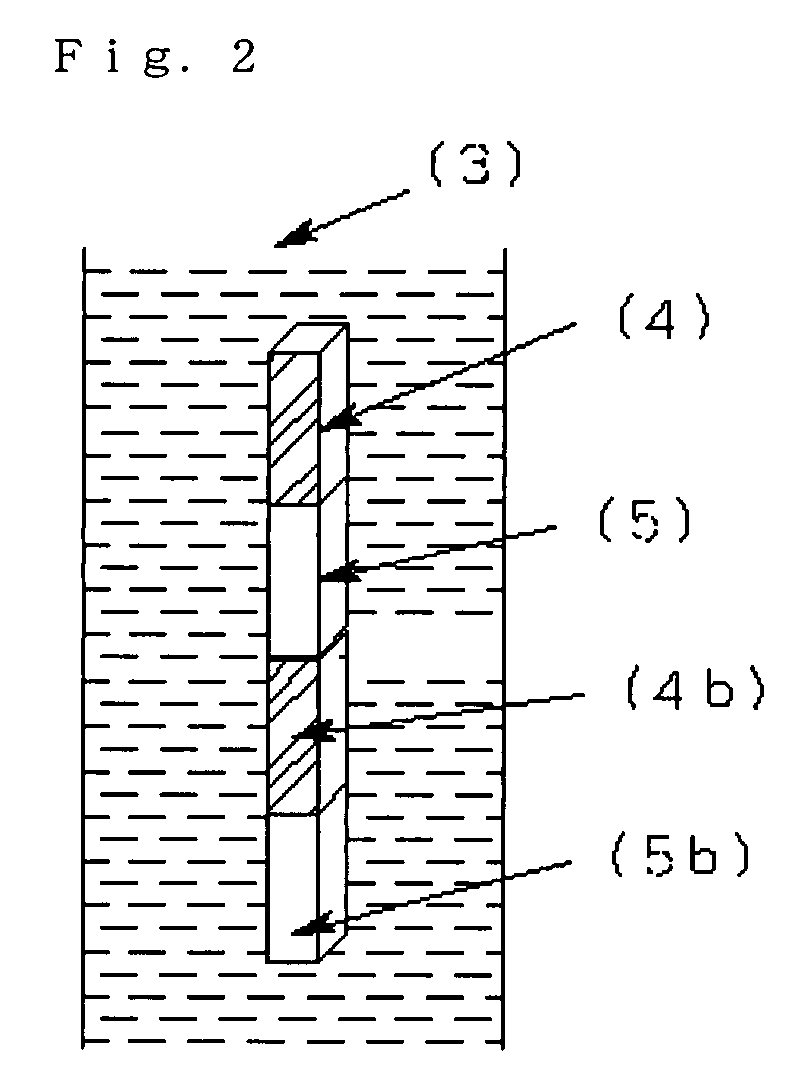

[0018]According to the present invention, one or more magnets are disposed in the circulation path of a magnetic fluid. Alternatively part of the fluid circulation path may be defined by one or more magnets. Preferably, the magnets are plated with nickel or the like on the surfaces directly contacting the magnetic fluid and the plated surfaces are coated with a surfactant having the same ionic charge as the surfactant used for coating the particulate ferromagnetic material dispersed in the magnetic fluid. The above treatment allows direct application of the magnetic field to the magnetic fluid with reduced flow resistance.

[0019]Preferably, a ferromagnetic material having strongly temperature-dependent saturation magnetization such as a ferrite comprising manganese and zinc is employed as the particulate ferromagnetic material of the magnetic fluid. The particulate ferromagnetic material has an average particle size less than about 10 nm, preferably less than 6 nm, most preferably ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com