Method of Manufacturing Sample for Atom Probe Analysis by FIB and Focused Ion Beam Apparatus Implementing the Same

a technology of atom probe and focused ion beam, which is applied in the direction of scanning probe techniques, instruments, vacuum evaporation coating, etc., can solve the problems of difficult to analyze a fine specified site by the ap, transplantation piece in the front from the joint part flies and is lost, and achieves the effect of easy implementation of the transplanting/bonding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

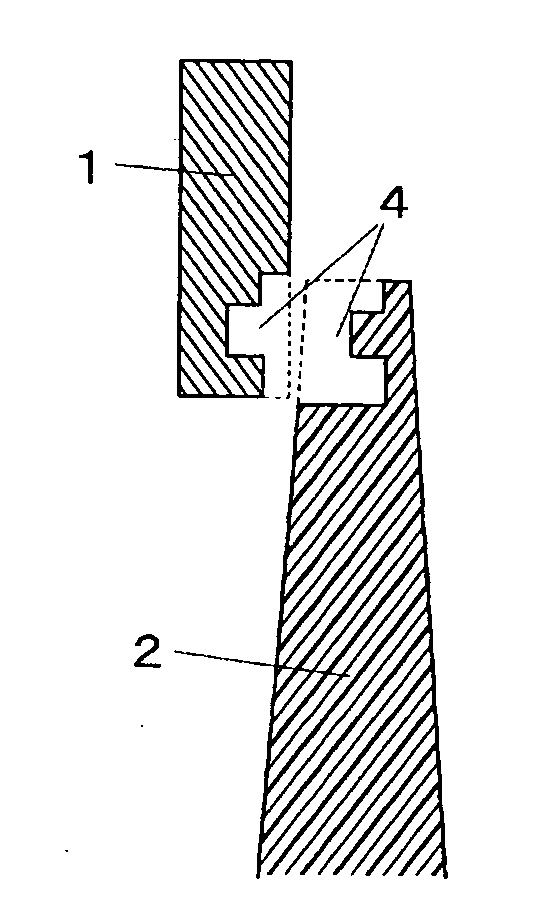

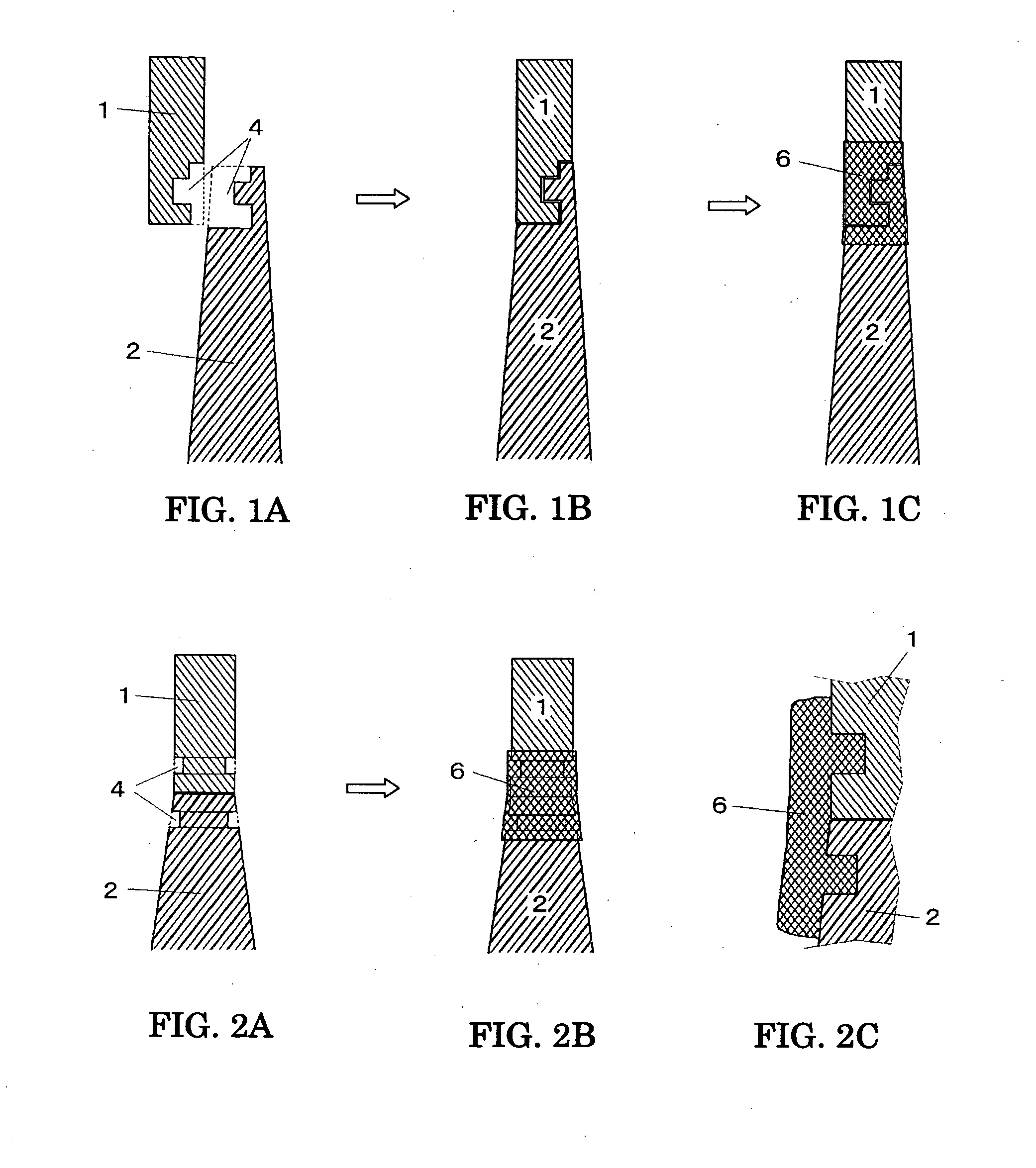

[0025]First, a first bonding / fixing technique concerned with the invention is explained while referring to FIGS. 1A-1C. In the drawing, 1 is a cut-off block-like observation sample piece, and it is carried to a tip portion of a base needle 2 by a fine probe operated by the manipulator similarly to the conventional technique shown in FIG. 6B. Although FIG. 1A is a form at this time, in tip portions of a base part of the observation sample piece 1 and the base needle 2, a mutually meshing concave / convex shape 4 is already engraved. The concave shape 4 is formed by the etching working by the FIB under a state in which the observation sample piece 1 is fixed to a tip of the fine probe by the FIB-CVD. The convex shape 4 is formed by the etching working by the FIB under a state in which a tip portion of the base needle 2 is retained by a base needle retention member attached to an FIB apparatus mentioned later. As shown in FIG. 1B, these both members are fitted with the concave and convex...

embodiment 2

[0028]A second bonding / fixing technique concerned with the invention is explained while referring to FIGS. 2A-2C. A form shown in FIG. 2A is a state in which a flat base part of the observation sample piece 1 is butt-jointed to a flat tip portion of the base needle 2 and, in both members, there is formed a circumference-like groove 4 as the concave / convex shape in a position slightly spaced from the joint face. As to this groove working, similarly to the previous example, the groove shape 4 may be formed by the etching working by the FIB under the state in which the observation sample piece 1 is fixed to the tip of the fine probe by the FIB-CVD, or the groove shape 4 may be formed by the etching working by the FIB under the state in which the tip portion of the base needle 2 is retained by the base needle retention member attached to the FIB apparatus, or there may be made so as to form the groove by temporarily fixing, under a state butt-jointed in raw intact, its joint portion by ...

embodiment 3

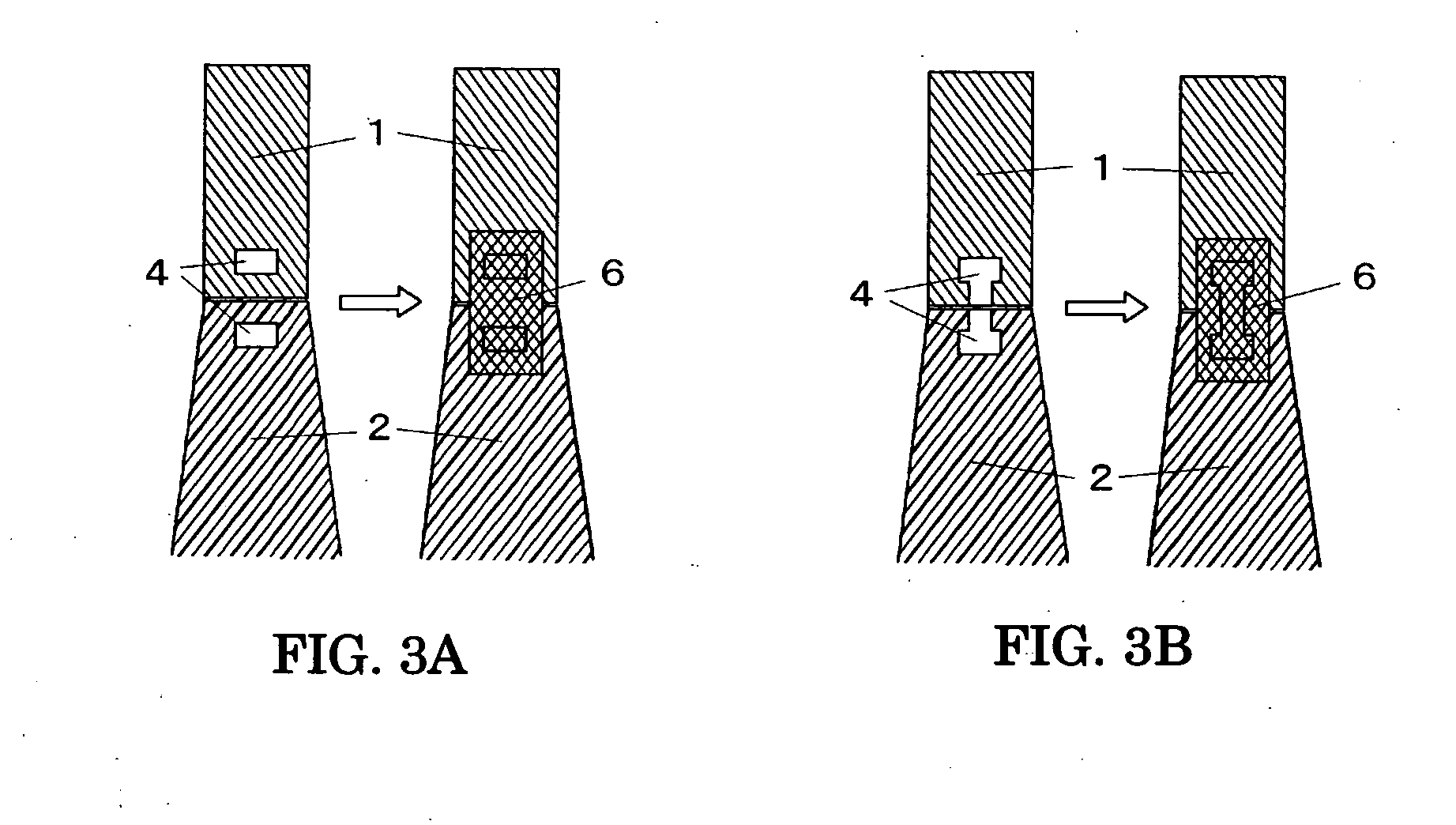

[0029]Two modified examples of the second bonding / fixing technique concerned with the invention are explained while referring to FIGS. 3A and 3B. In the previous example, although it is one which is under the state in which the flat base part of the observation sample piece 1 is butt-jointed to the flat tip portion of the base needle 2 and in which there is formed the circumference-like groove 4 in both-member positions slightly spaced from the joint face by the etching working of the FIB, the modified example shown here is one in which a hole is bored, not the groove. An embodiment shown in FIGS. 3A and 3B is one in which a quadrate hole 4 having faces intersecting perpendicularly to the needle axis is provided in both members by the etching working of the FIB. The deposition layer 6 is formed by the deposition working of the FIB so as to extend over these quadrate holes 4 formed in both members, and they are fixed by a bridge of the clamp form. A left side of FIG. 3A is a view sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com