Photonic crystal structure and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

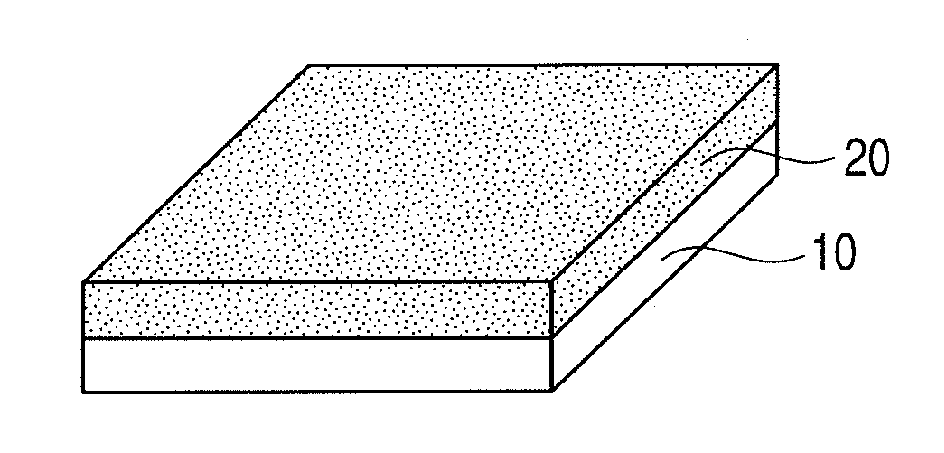

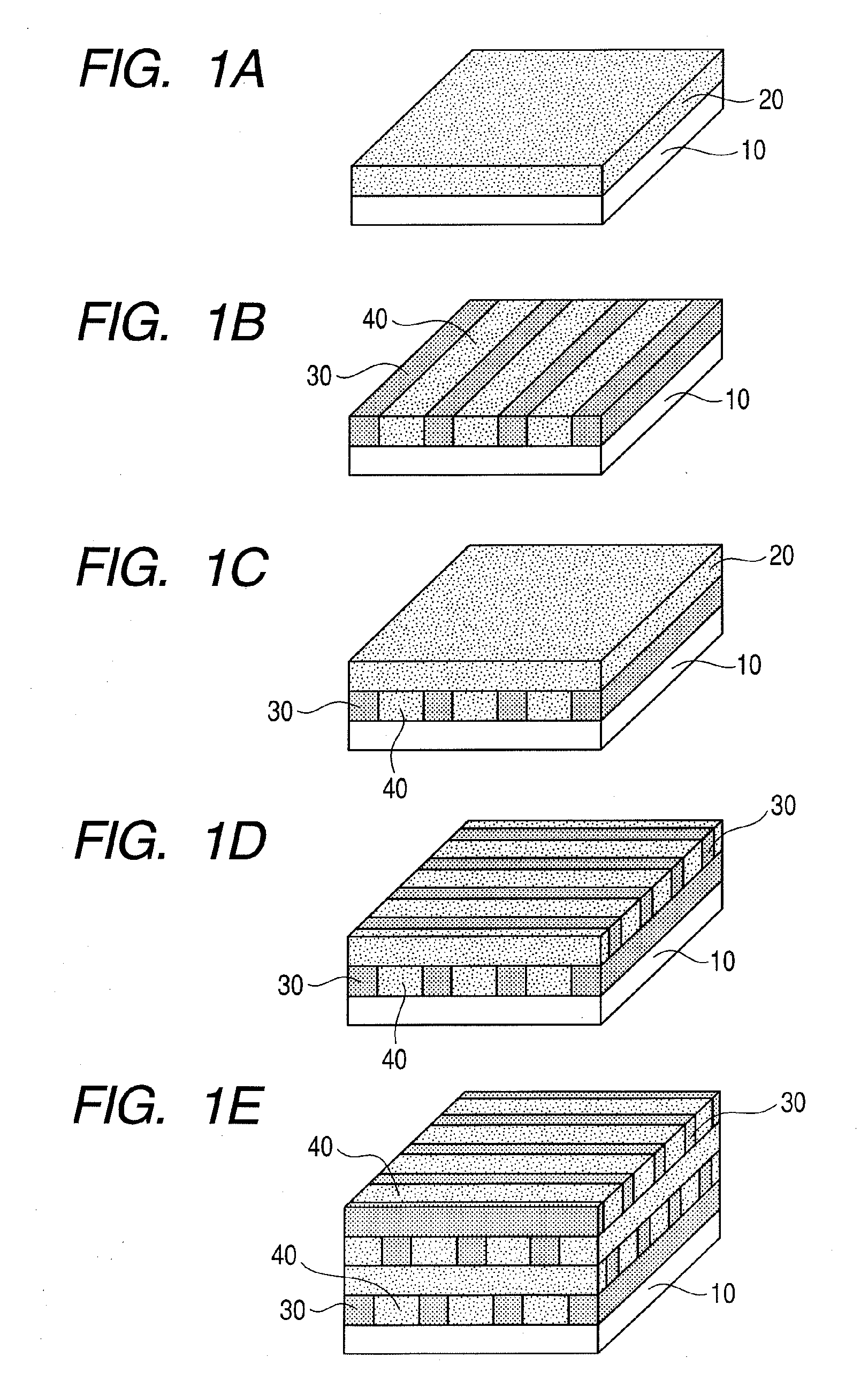

[0052]In exemplary embodiment 1, a description will be made of a method of manufacturing a three-dimensional photonic crystal in which a woodpile structure having a predetermined period is formed by repeating a film-forming step and an ion arrangement step a predetermined number of times. Since the method of manufacturing the three-dimensional photonic crystal in the present exemplary embodiment follows basically the same steps as the method of manufacturing the photonic crystal described in an exemplary embodiment of the present invention, FIGS. 1A to 1E are also used here to describe the present exemplary embodiment.

[0053]In FIGS. 1A to 1E, reference numeral 10 denotes a quartz substrate, and reference numeral 20 denotes the base material of a photonic crystal structure formed of an amorphous Si thin film (hereinafter referred to as the Si thin film).

[0054]First, a thin film is formed in a step of preparing a photonic crystal base material, as described below, as the base material...

exemplary embodiment 2

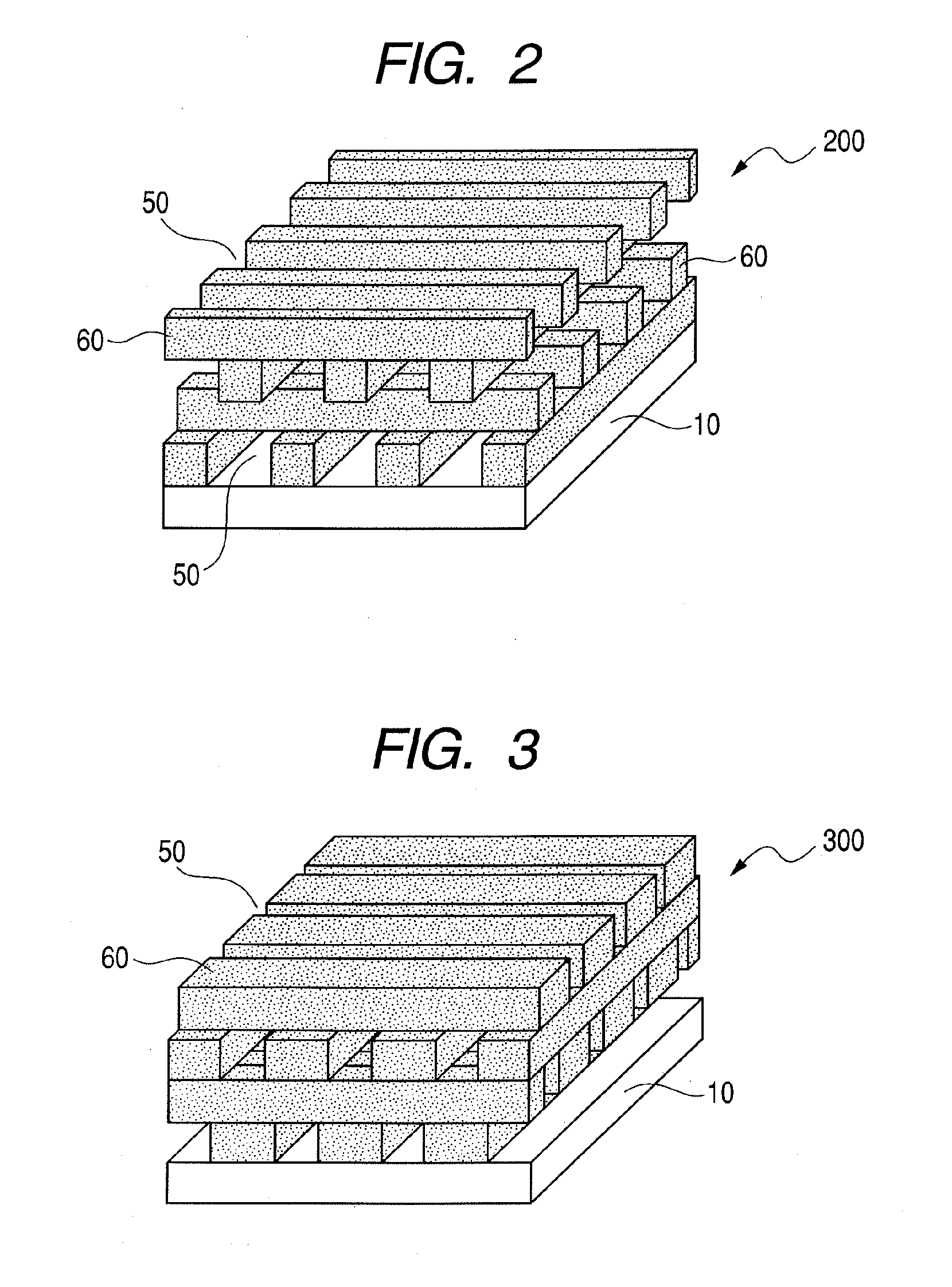

[0059]In exemplary embodiment 2, a description will be made of a constitutional example of a photonic crystal structure to be newly fabricated using the photonic crystal formed in exemplary embodiment 1. Since the present exemplary embodiment is based on a structure basically the same as the photonic crystal structure illustrated in FIG. 2 in the above-described exemplary embodiment of the present invention, FIG. 2 is also used here to describe the present exemplary embodiment. As described with reference to the photonic crystal structure illustrated in FIG. 2 in the above-described exemplary embodiment of the present invention, this photonic crystal is equivalent to the photonic crystal illustrated in FIG. 1E from which the base material part 40 is removed. That is, the rods 60 correspond to the base material part 30 in FIGS. 1A to 1E, and at least one of molecules, atoms and ions different from the constituent element of the base material is arranged in the photonic crystal base m...

exemplary embodiment 3

[0063]In exemplary embodiment 3, a description will be made of a constitutional example of a photonic crystal structure which is newly fabricated using the photonic crystal formed in exemplary embodiment 1 and is different from the photonic crystal structure of exemplary embodiment 2. FIG. 3 illustrates a schematic view used to describe the photonic crystal structure of the present exemplary embodiment. In the present exemplary embodiment, there is used a step which further includes a step of selectively removing the region in which ions have been implanted, following the above-described step of implanting ions. For example, the base material part 30 in FIG. 1E, i.e., a part of Si containing Ga ions, is selectively removed using a solution. Any solutions, including a hydrochloric acid, which dissolve Ga but not Si can be used. First, the photonic crystal structure illustrated in FIG. 1E is placed in the solution and a wait is made until the base material part 30 completely dissolves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com