Resonance driven glow plug torch igniter and ignition method

a glow plug torch and ignition method technology, which is applied in the direction of gaseous heating fuel, combustion types, stoves or ranges, etc., can solve the problems of heavy, complex and cumbersome conventional systems, and achieve the effects of high reliability, easy integration into complex assemblies, and easy extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

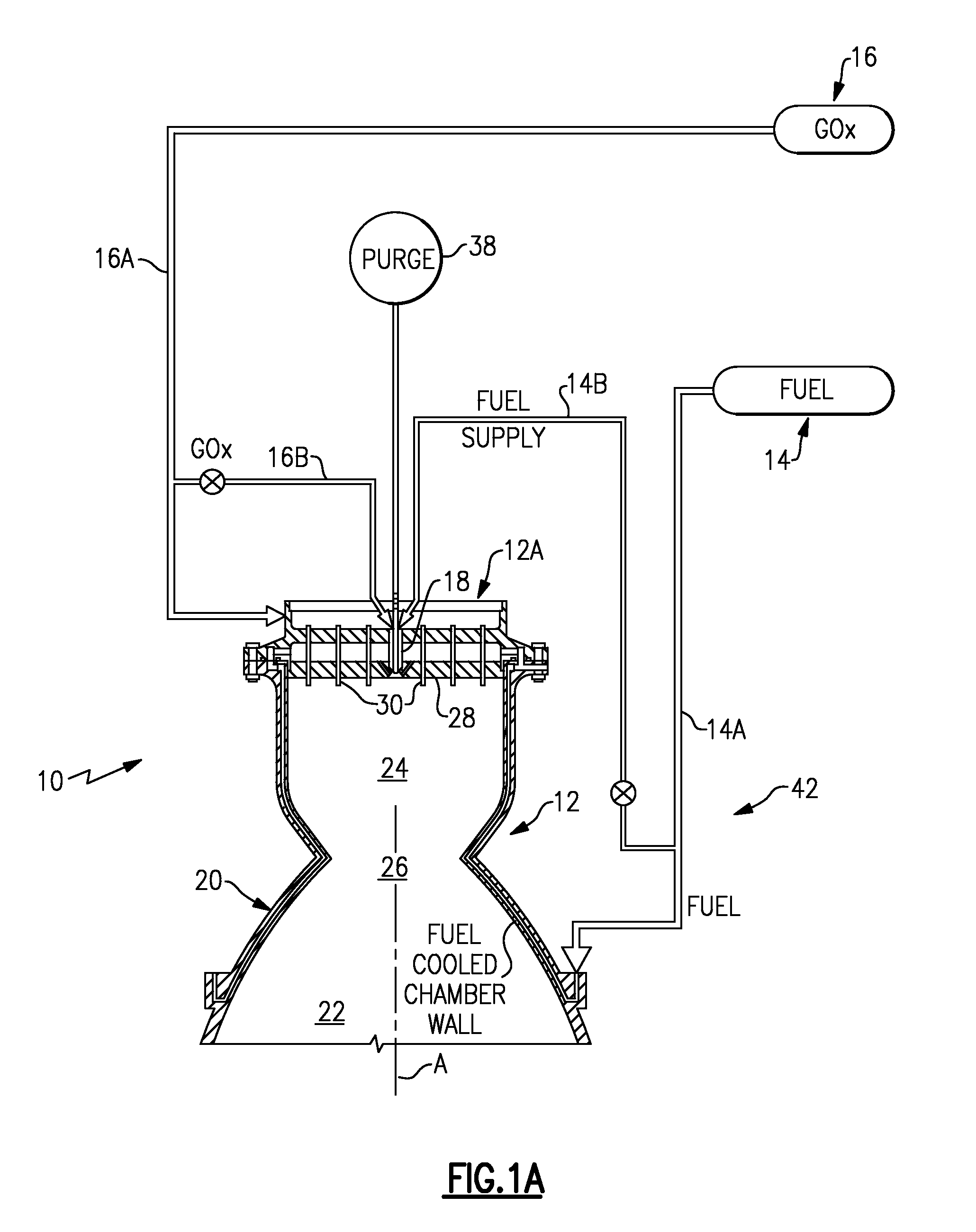

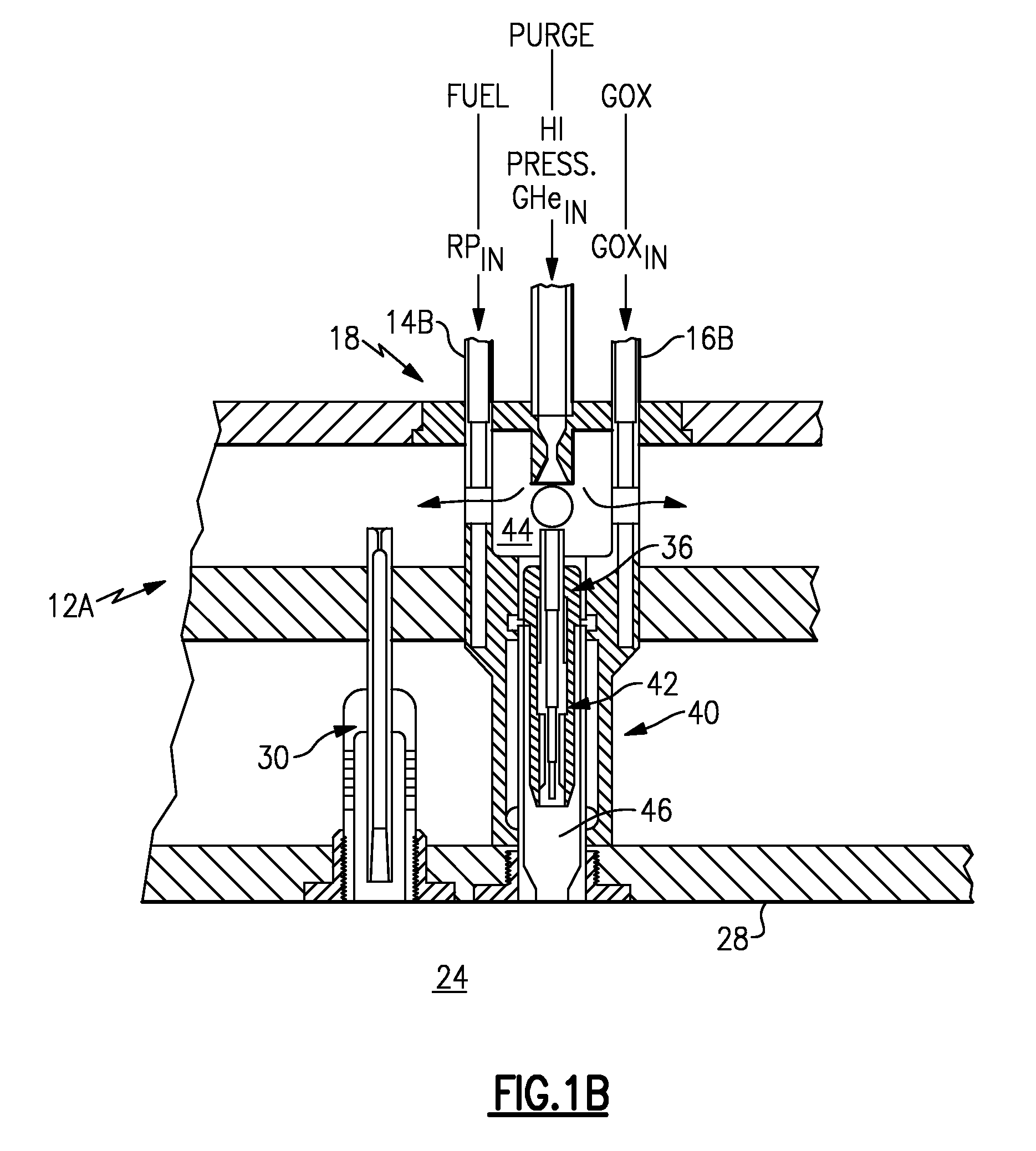

[0013]FIG. 1 illustrates a general schematic view of a combustor 10. A rocket engine combustor is used in this example embodiment. The combustor 10 generally includes a combustion chamber assembly 12, a fuel system 14, an oxidizer system 16 and an ignition system 18. The fuel system 14 and the oxidizer system 16 provide a gaseous ignitable propellant combination to the combustor 10, however, other propellant systems such as liquid will also be usable.

[0014]The combustion chamber assembly 12 is defined by a fluid cooled wall 20 about a center axis A. The fluid cooled wall 20 defines a nozzle section 22, a combustion chamber section 24 upstream of the nozzle section 22, and a combustion chamber throat 26 therebetween. The combustion assembly 12 includes an injector system section 12A with an injector face 28 having a multitude of fuel / oxidizer injector elements 30 (shown somewhat schematically) which receive fuel which passes first through the fuel cooled combustion chamber wall 20 fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com