System, Apparatus and Method for Monitoring Accumulation of Fluids in a Containment Tank

a technology for containment tanks and fluid accumulation, which is applied in the direction of liquid handling, instruments, packaged goods types, etc., can solve the problems of insufficient inspection and testing, and insufficient monitoring of fluid accumulation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

operation example

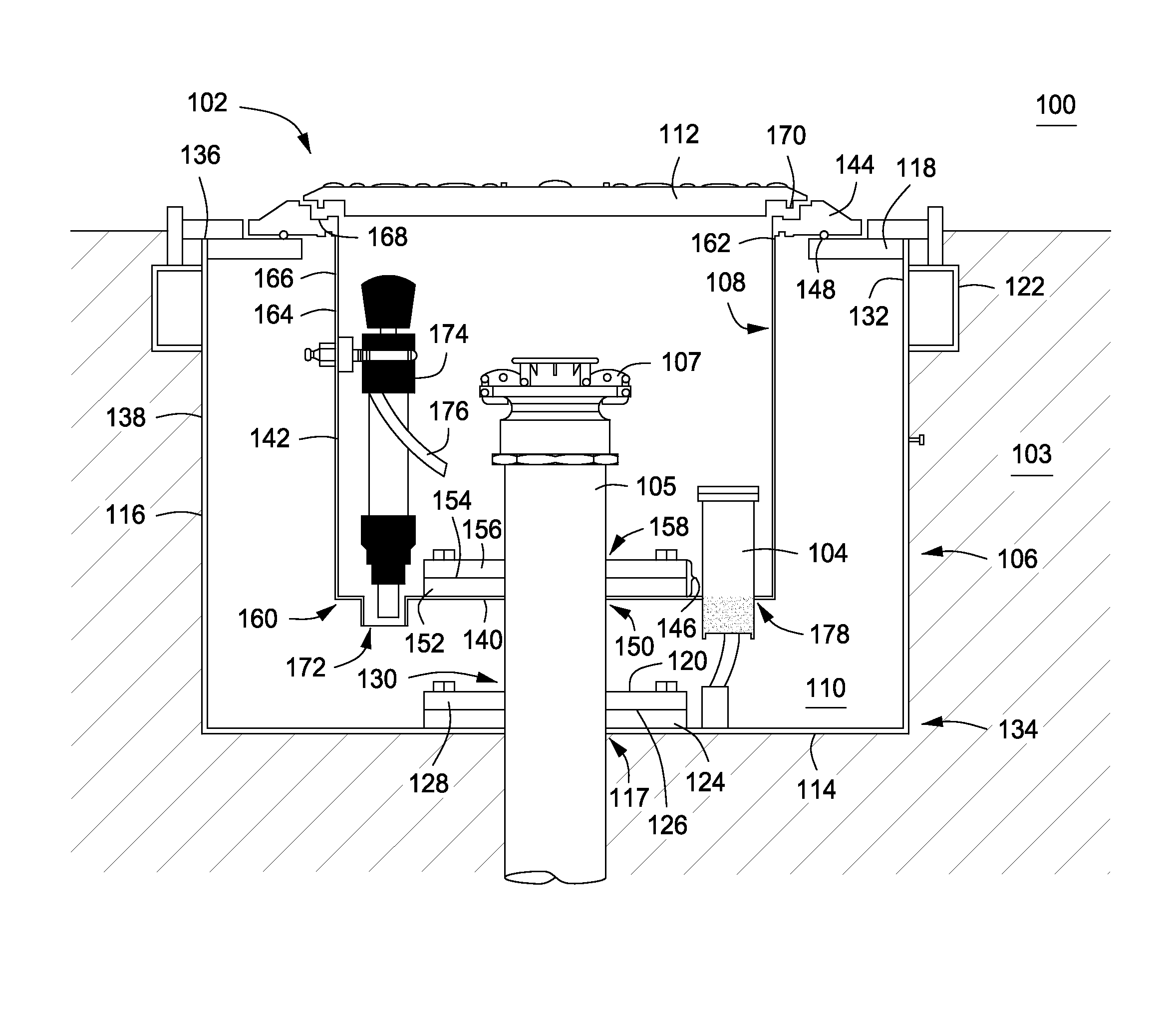

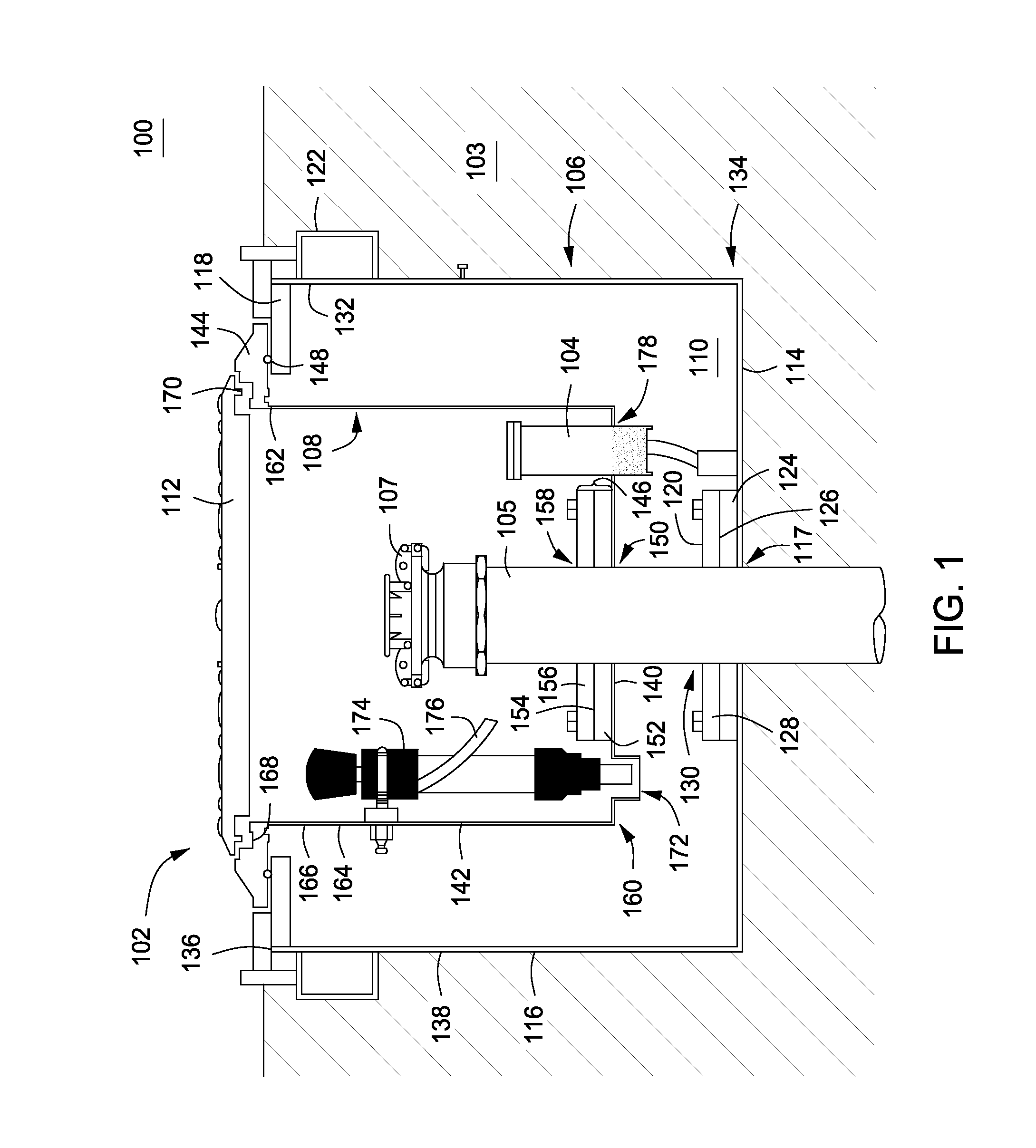

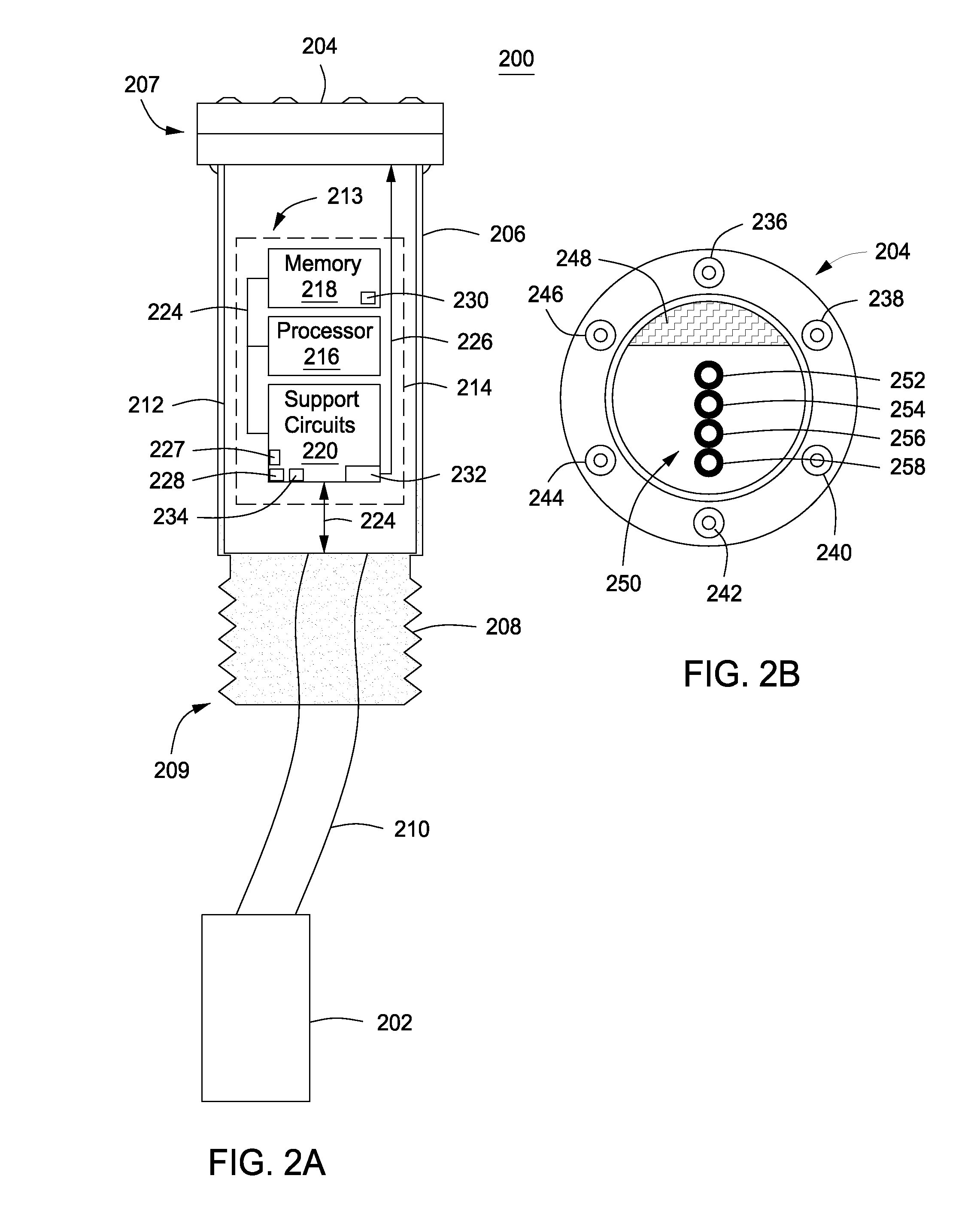

[0082]FIG. 3 is a flow chart illustrating an example of a flow 300 for detecting an accumulation of fluids that may accumulate in an accumulation zone of the containment tank. For convenience, the flow 300 is described with reference to the system 100 of FIG. 1 and the monitoring device 200 of FIG. 2. The flow 200, however, may be carried out using other architectures as well.

[0083]The flow 300 starts at termination block 310, after the monitoring device 200 is installed in containment tank 102. After termination block 310, the flow 300 transitions to process block 320.

[0084]At process block 320, the timing and / or clock circuitry 227 wakes up the processor 216 by issuing an electrical signal to the processor 216. This electrical signal may be issued on a periodic basis, and as such may indicate a predetermined amount of period (“time period”) has passed. This predetermined time period may be, for example, about 24 hours. Alternatively, the predetermined time period may ranges from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com