Carrier, process for producing same, bioreactor, and chip for surface plasmon resonance analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

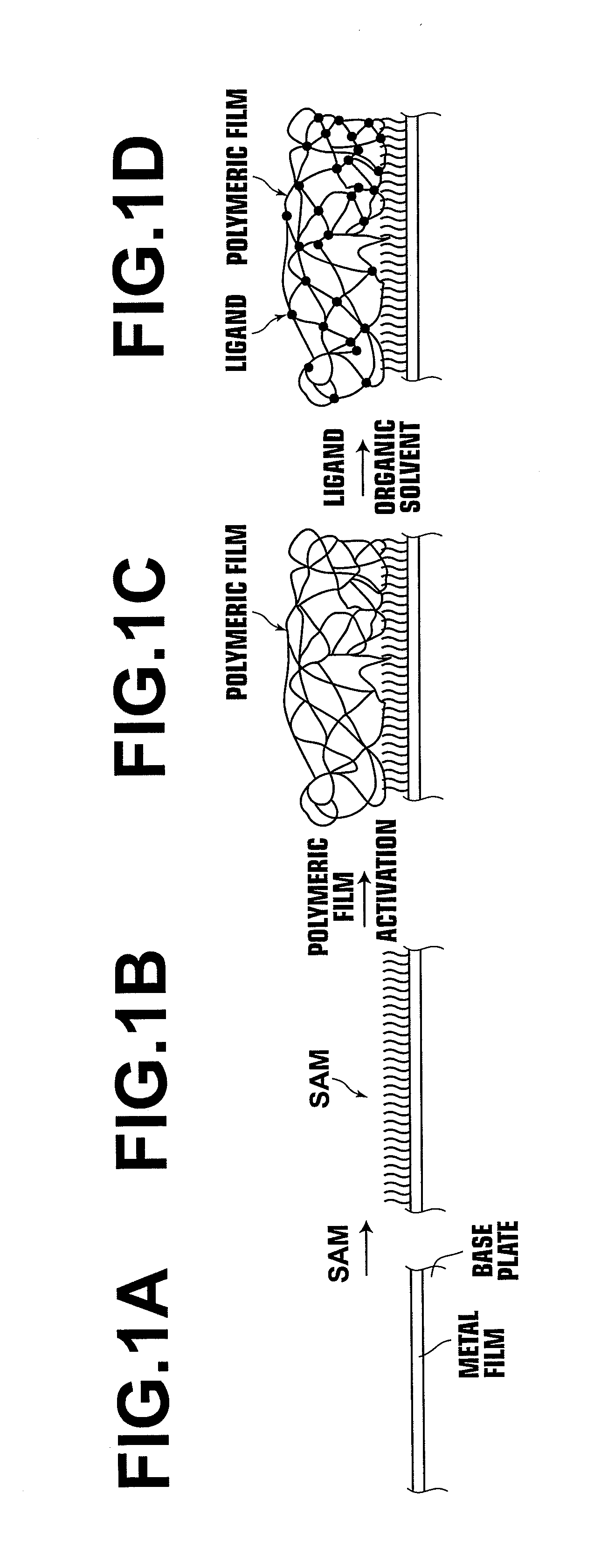

(Preparation of SAM)

[0196]A chromium film having a thickness of 3 nm and a gold film having a thickness of 20 nm were formed on a polystyrene microwell plate (96Well Microwell Plate, supplied by Nunc) by use of a sputtering technique. Thereafter, a solution, which contained 10 μmol of 6-aminohexanethiol (supplied by Aldrich) dissolved in 8 ml of ethanol and 2 ml of ultra pure water, was allowed to undergo reaction with the gold film, which had been formed with the sputtering technique described above, at a temperature of 40° C. for one hour. The resulting SAM was then washed one time with ethanol and was thereafter washed one time with ultra pure water.

(Activating Esterification of CMD)

[0197]A CMD solution was prepared with processing wherein CMD (molecular weight: 1000,000, supplied by Meito Sangyo Co., Ltd.) was dissolved in ultra pure water so as to have a concentration of 0.5% by weight. Thereafter, a mixed solution, which contained 0.4M of EDC (i.e., 1-(3-dimethylaminopropyl)-3...

example 2

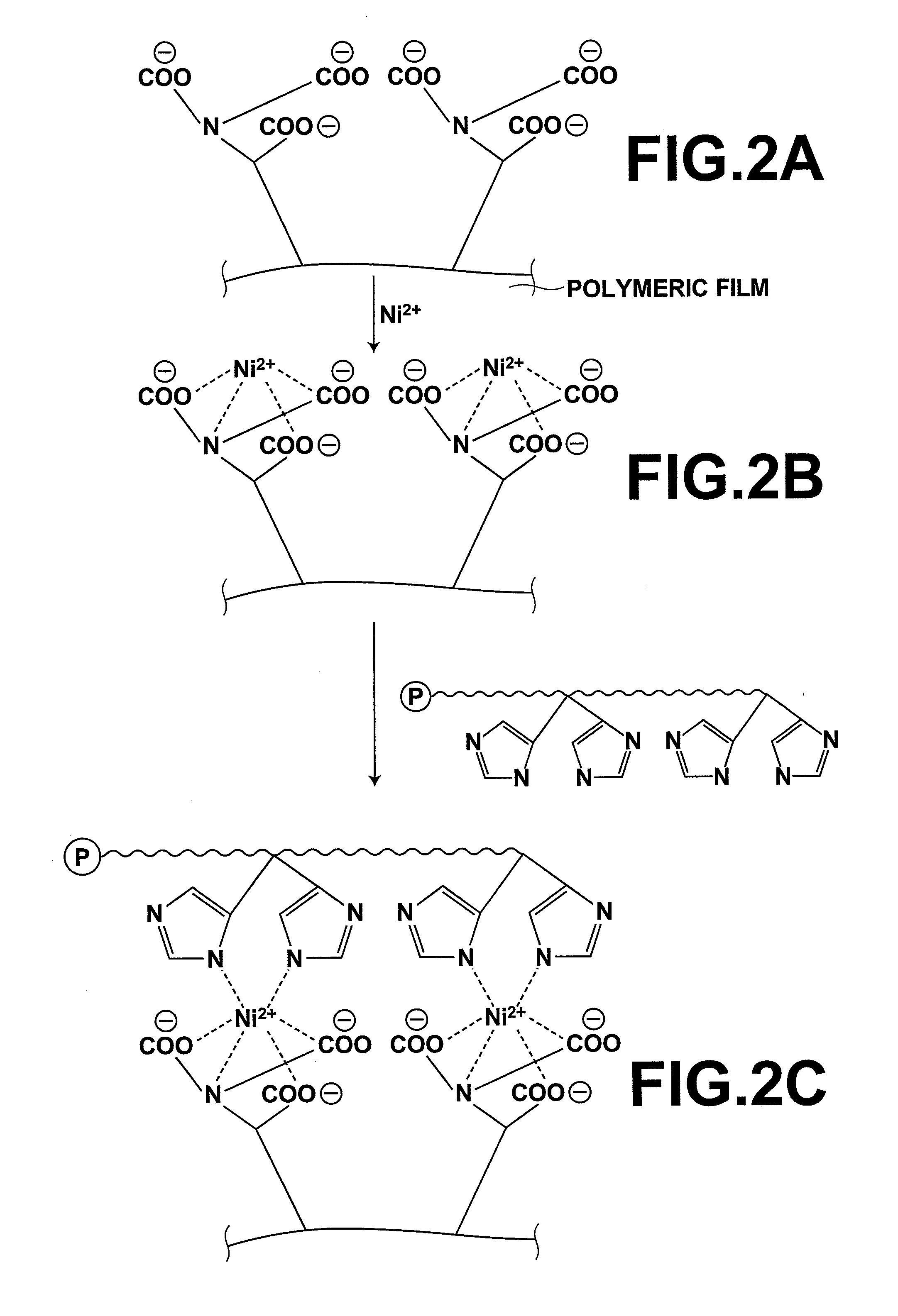

[0201]A carrier was prepared in the same manner as that in Example 1, except that, at the time of the binding of AB-NTA, a solution was prepared by the addition of 0.2 mmol of EDC and 0.04 mmol of NHS to 1 ml of DMSO, 50 μl of the thus prepared solution was added onto the CMD film, and the solution was then allowed to undergo the reaction at the room temperature for 30 minutes.

examples 3 , 4

Examples 3, 4, and 5

[0202]A carrier was prepared in the same manner as that in Example 1, except that the kind of the metal source was changed as listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polarity | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

| Hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com