Metal powder for use in an additive method for the production of three-dimensional objects and method using such metal powder

a three-dimensional object and additive technology, applied in the direction of additive manufacturing, process efficiency improvement, transportation and packaging, etc., can solve the problem that the conventional precipitation hardening process does not work for parts, and achieve the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

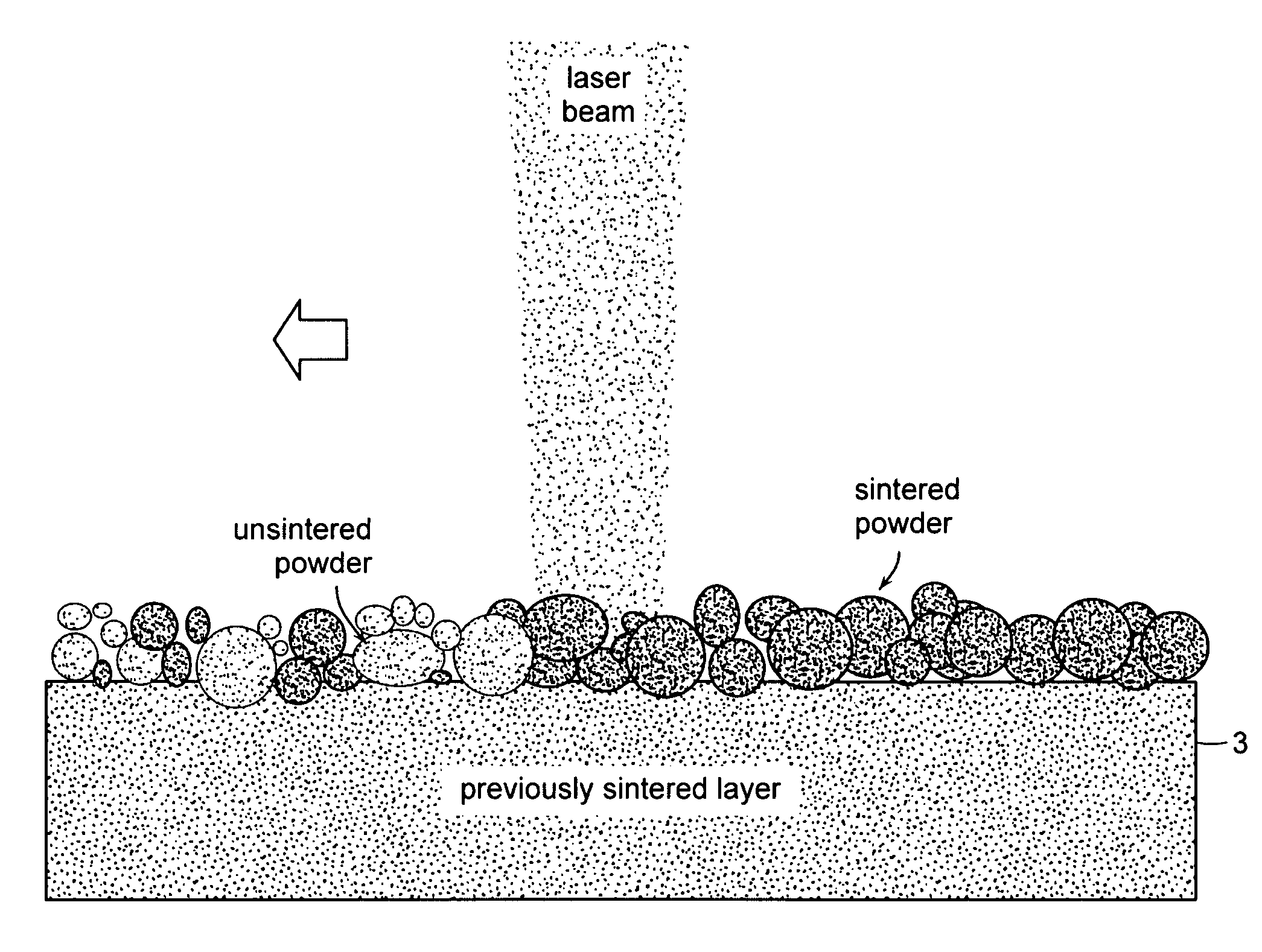

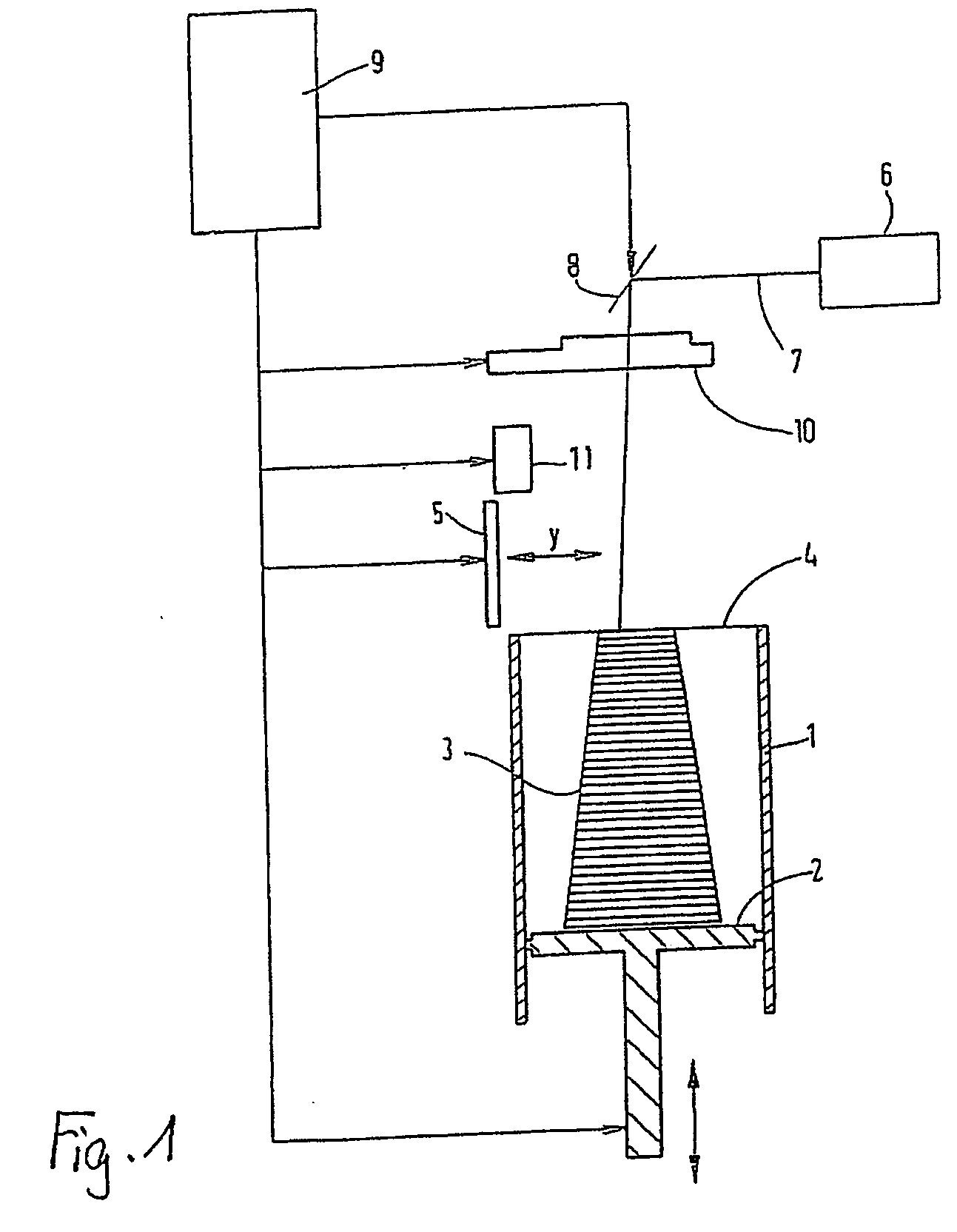

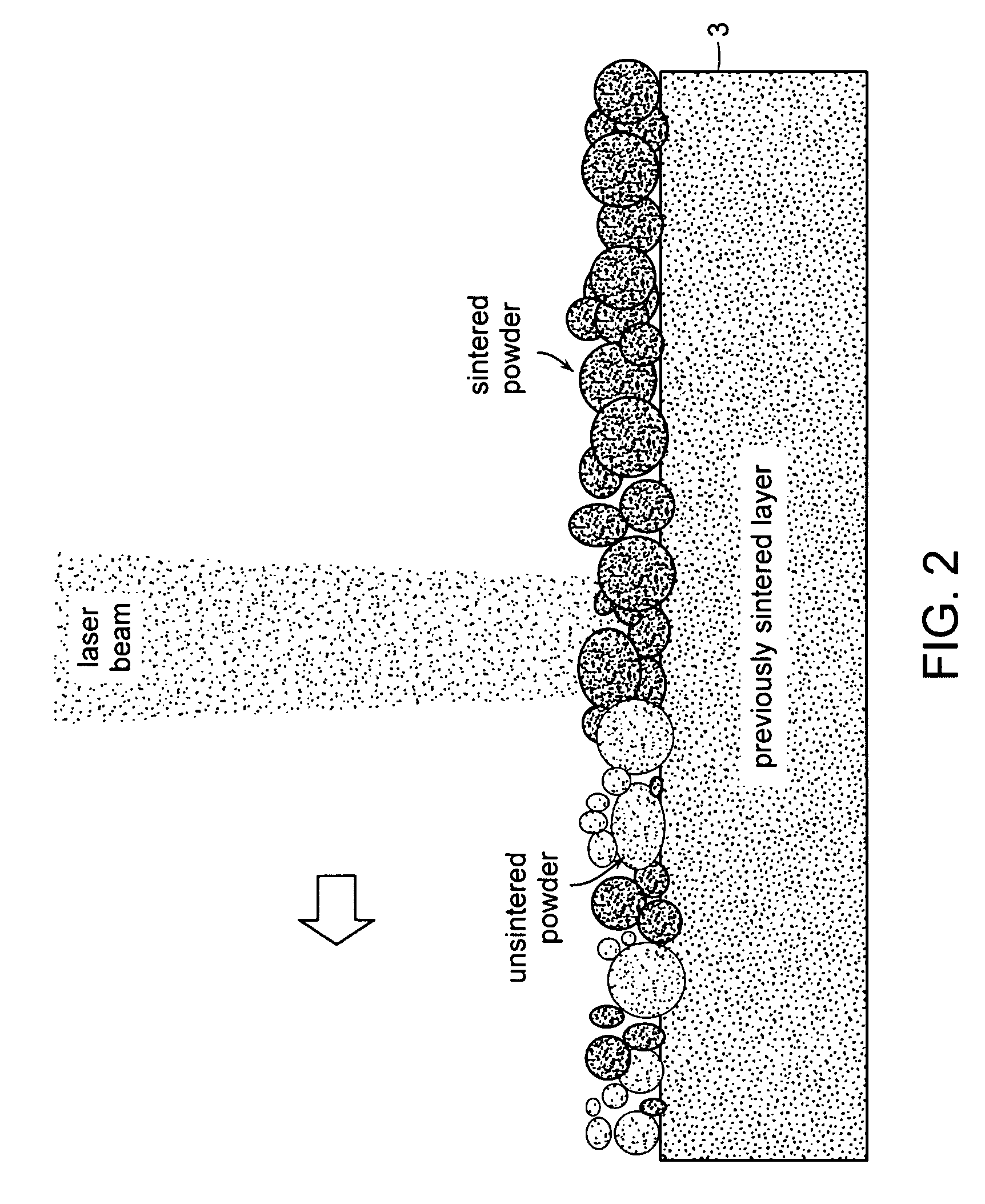

[0072]The invention will now be described with reference to the direct metal laser sintering process as an example for an additive manufacturing method. As shown in FIG. 1 the laser sintering apparatus comprises a build container 1 open at the top with a support 2 carrying the object 3 to be built. The support 2 is movable in the build container 1 in a vertical direction and is adjusted in such a way that the layer of the object which is to be solidified defines a working plane 4. A layer generating device 5 for generating a layer of pulverulent build material on the support or on a previously applied layer is provided. The laser sintering apparatus further comprises a laser 6 emitting a laser beam 7 which is deflected by a deflection unit 8 and passes through an optical unit 10 which focuses the laser beam onto the working plane 4. A control unit 9 controls the deflection unit 8 and the optical unit 10 in such a way that the laser beam 7 can be focussed to any position in the worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com