Cooling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Operation of Embodiment

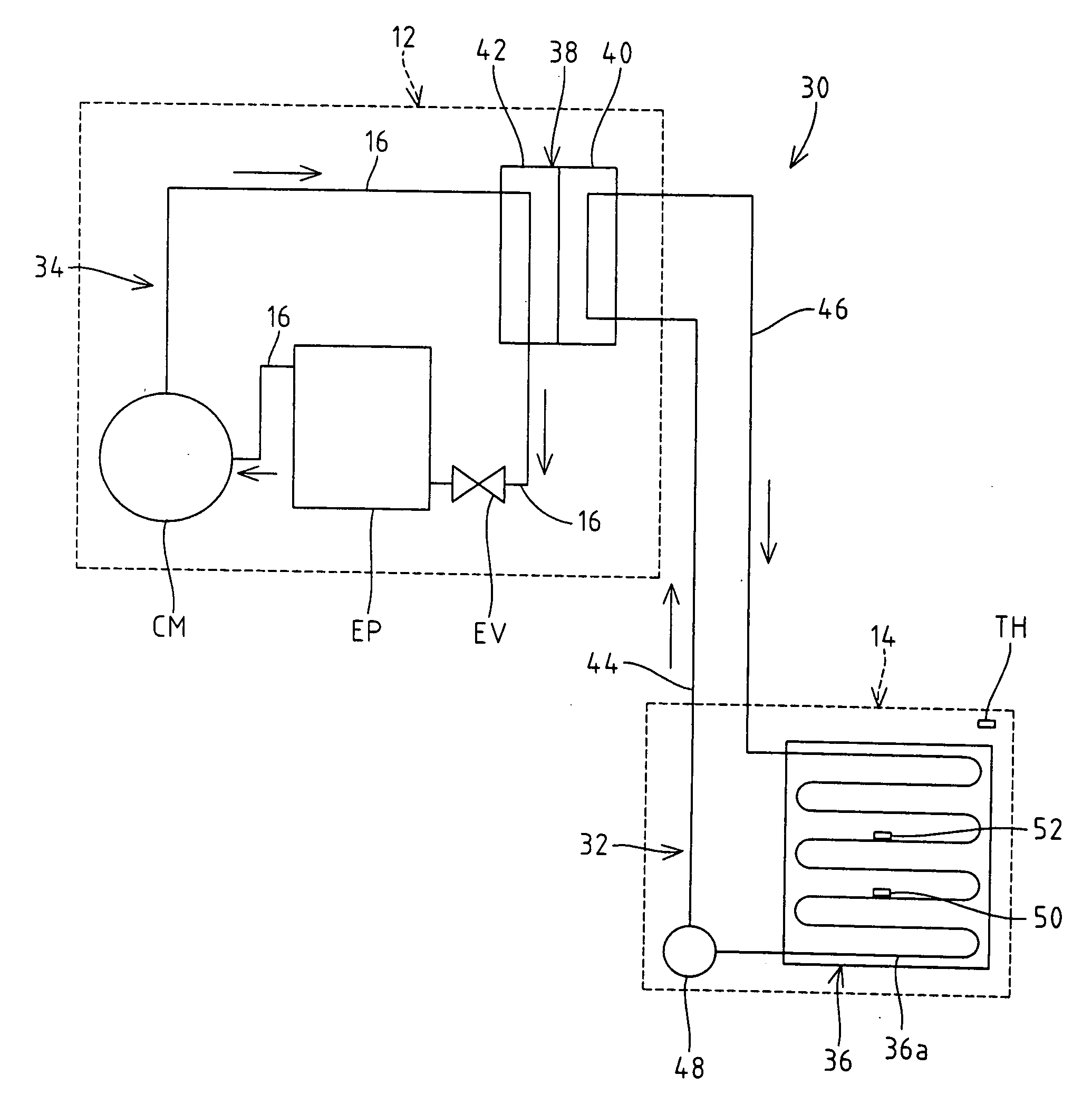

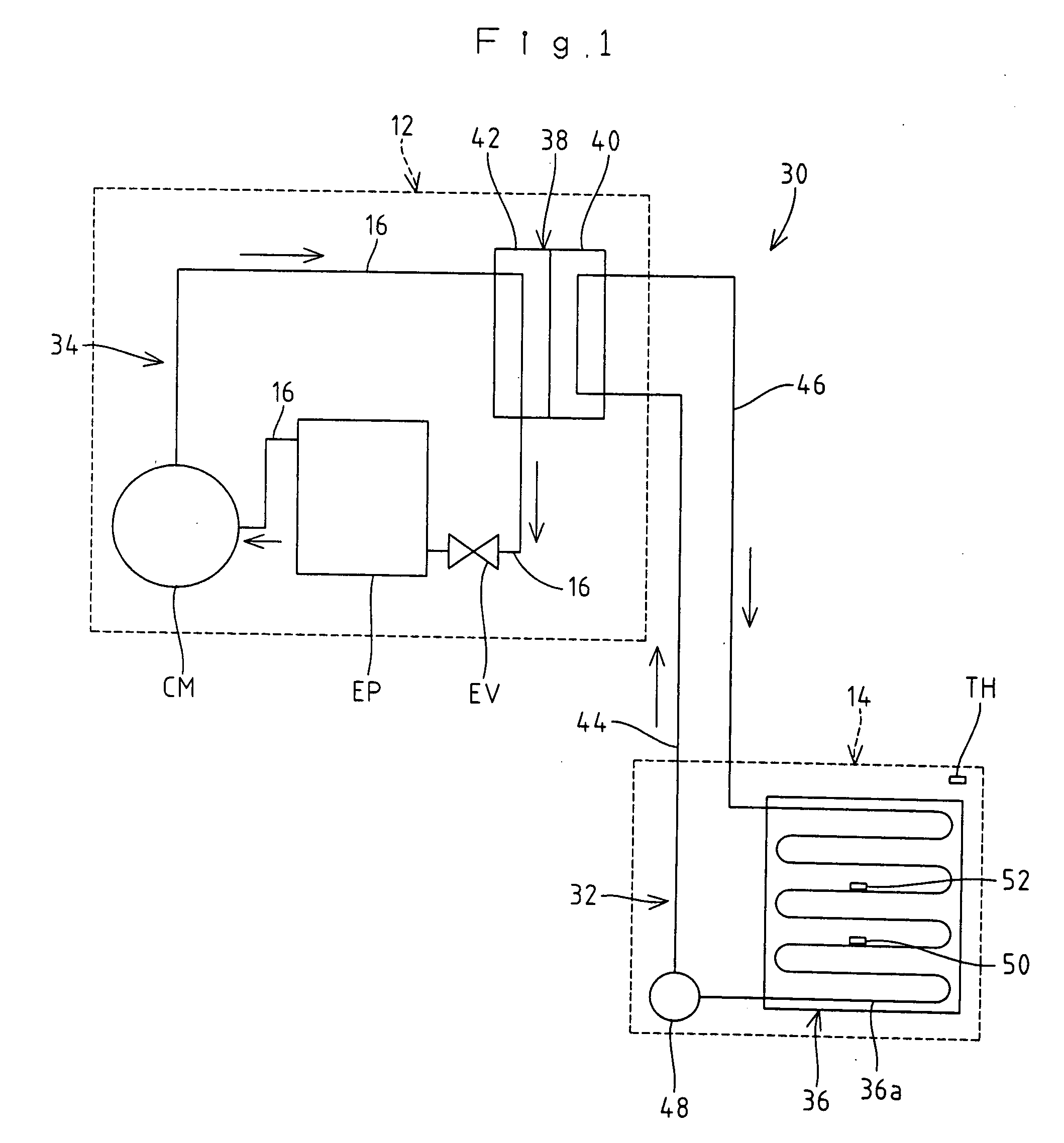

[0029]The operation of the cooling apparatus 30 according to the embodiment will be described next. In the primary circuit 32 of the cooling apparatus 30, a gas-phase primary coolant discharges heat to be liquefied while flowing through the heat discharge duct 36a of the condenser 36 to have phase transition from a gas-phase primary coolant to a liquid-phase primary coolant. The liquid-phase primary coolant is pumped out from the pump 48, flows into the first heat exchanging section 40 through the liquid piping 44, is vaporized by heat exchange with the gas-phase secondary coolant flowing through the second heat exchanging section 42 to have phase transition from a liquid-phase primary coolant to a gas-phase primary coolant. Then, the gas-phase primary coolant flows into the condenser 36 through the gas piping 46. In this manner, the circulation cycle of the primary coolant between the condenser 36 and the first heat exchanging section 40 is repeated.

[0030]Mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com