Master electrode and method of forming it

a technology of master electrodes and master electrodes, applied in the direction of microstructured devices, electrical equipment, printed circuit manufacture, etc., can solve the problems of exponential dependence of current density, increased etching rate or plating rate, and increased problem of exacerbated problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

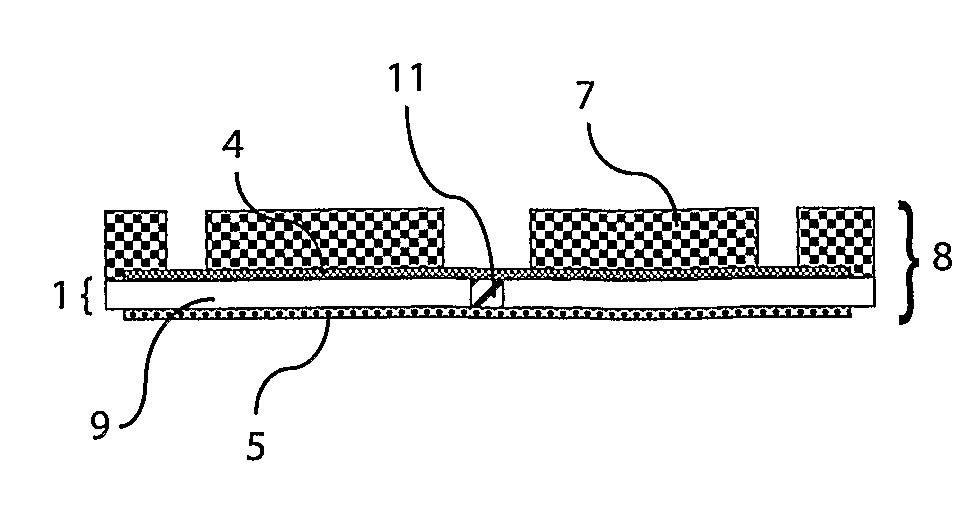

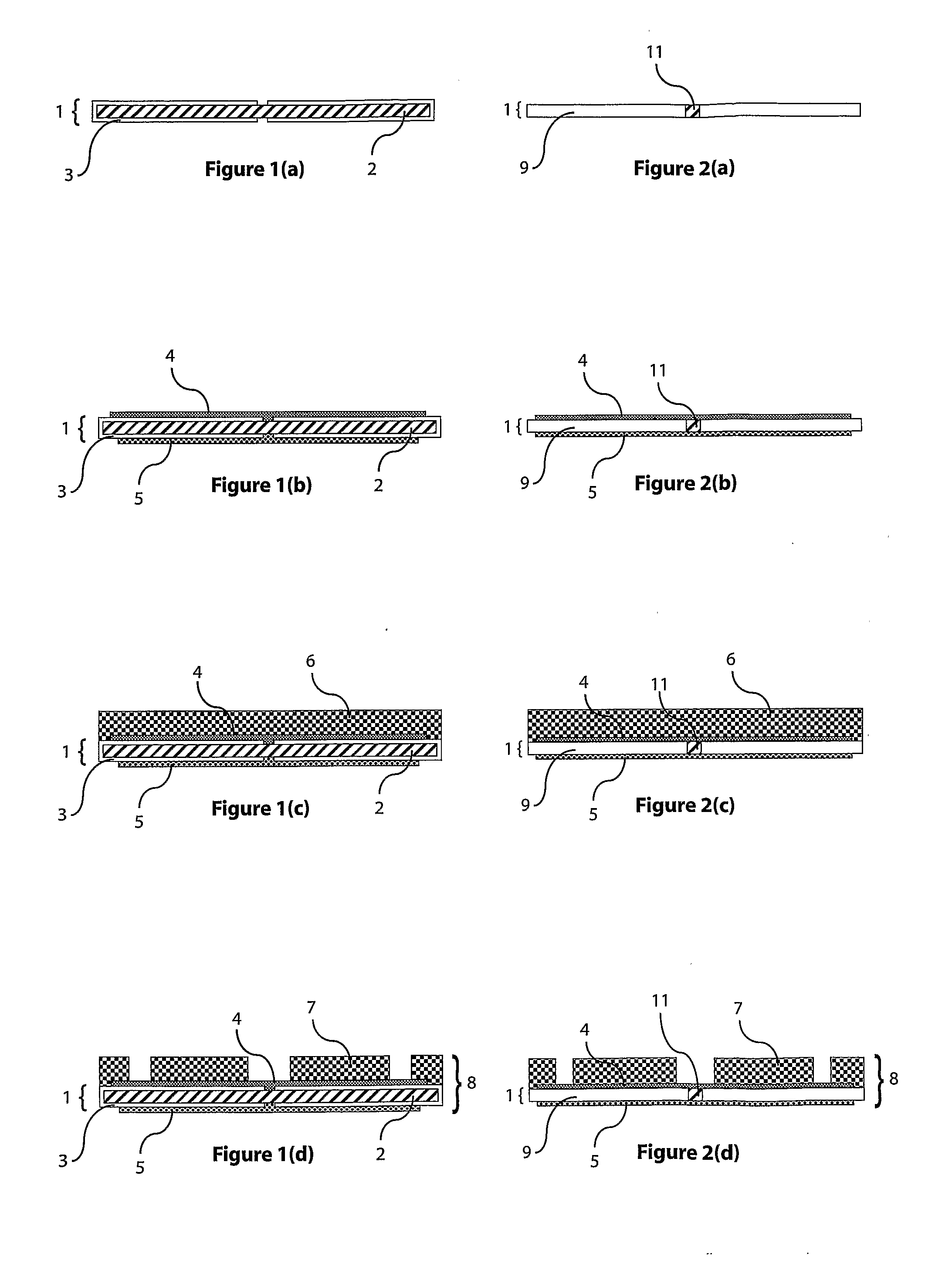

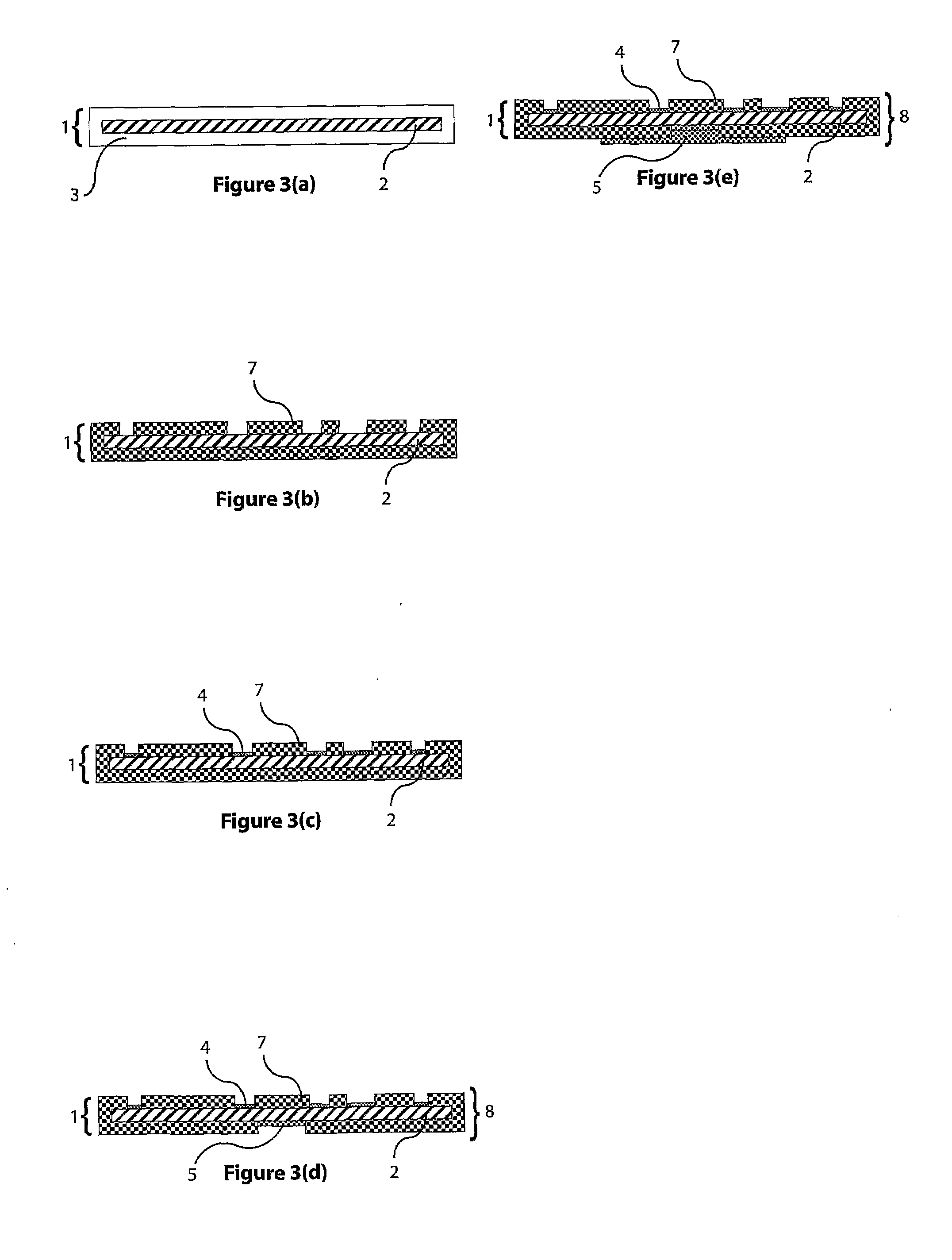

[0046]Below, several embodiments of the invention will be described with references to the drawings. These embodiments are described in illustrating purpose in order to enable a skilled person to carry out the invention and to disclose the best mode. However, such embodiments do not limit the invention, but other combinations of the different features are possible within the scope of the invention.

[0047]When etching and / or plating is performed on a substrate provided with a seed layer, which conducts the current at the substrate, it occurs that a substantial potential difference occurs across the seed layer. This being especially true in thin seed layers and at high etching / plating currents. If a potential difference of more than about 1% is present over the electrochemical cells as a result of a potential difference over the surface of the seed layer, the current densities in the electrochemical cells will vary in such an extent that a height difference is observable in the etched / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current densities | aaaaa | aaaaa |

| current densities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com