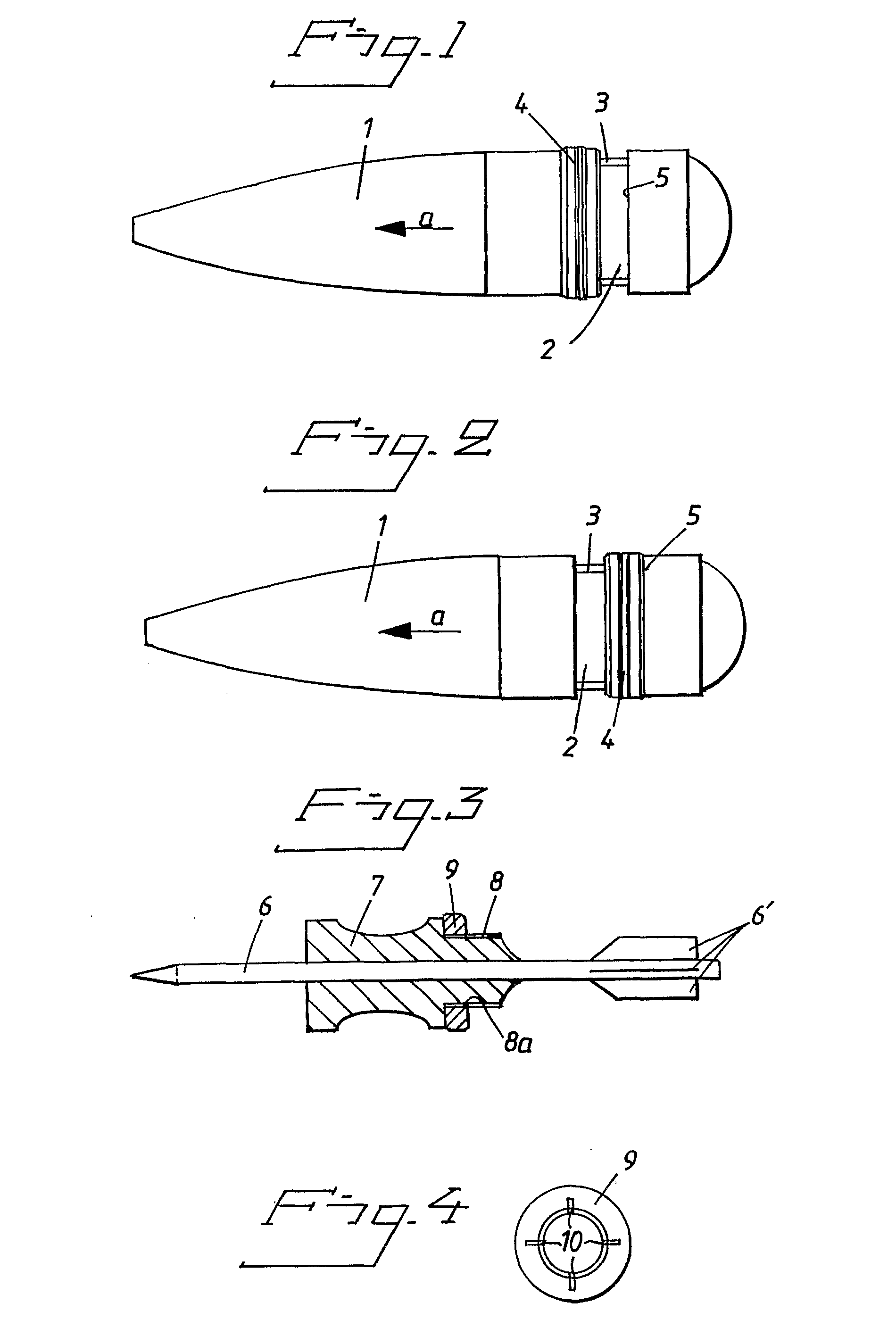

[0020]According to the present invention the band, in its basic its design, instead of being pressed down into a groove in the artillery

projectile, is joined to said projectile by threading it onto the projectile body. Since each banded artillery projectile must normally have the same

diameter in front of the band as behind it, and since in the method according to the invention threading the band onto the projectile body does not simultaneously involve a reduction in the

diameter of the band, the method according to the invention means that artillery projectiles with

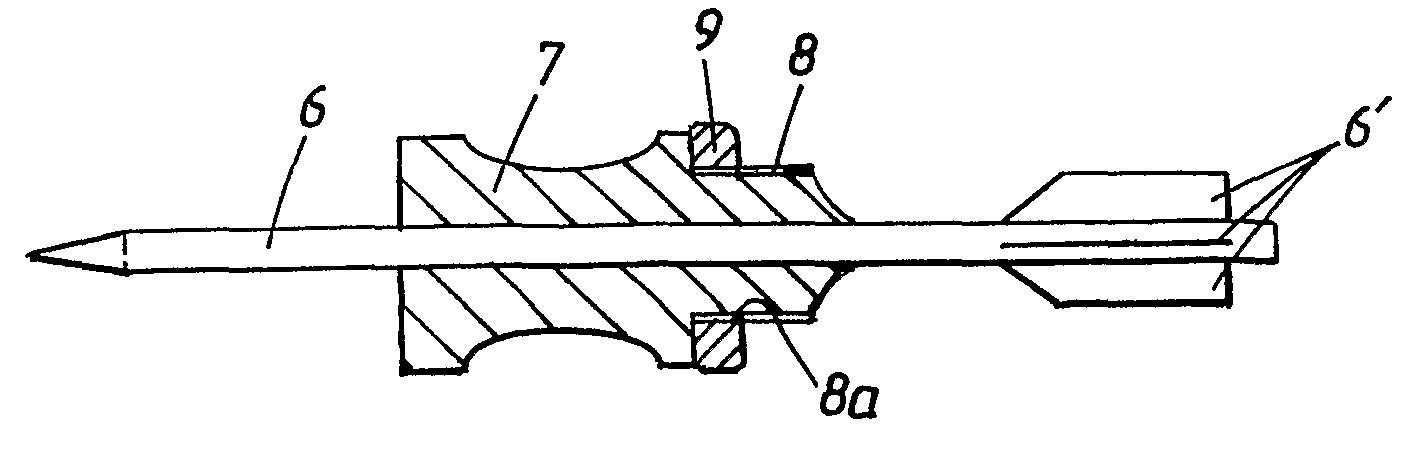

metal bands threaded on are normally manufactured in the form of at least two parts joined together. According to this variant of the invention, one of these two parts is formed with a reduction-turned and threaded end section, against the inner part of which the band is threaded on and the outer part of which is screwed into a similarly threaded recess in the other part of the projectile. In the case of banded projectiles manufactured in the manner outlined above, the band once threaded on will come to rest in a sunken groove, which towards one end of the projectile is defined by the end edge of the reduction turning and towards the other end of the projectile is defined by the end edge of the other projectile part.

[0021]A special case, which will be discussed in more detail below, are banded so-called discarding sabots on sub-calibre hard-core projectiles.

[0022]In its simplest form, therefore, the present invention comprises a method for fixing the internally threaded band on artillery projectiles by means of an external

screw thread arranged on the latter, instead of pressing the band into a groove in the projectile. This new method holds several advantages.

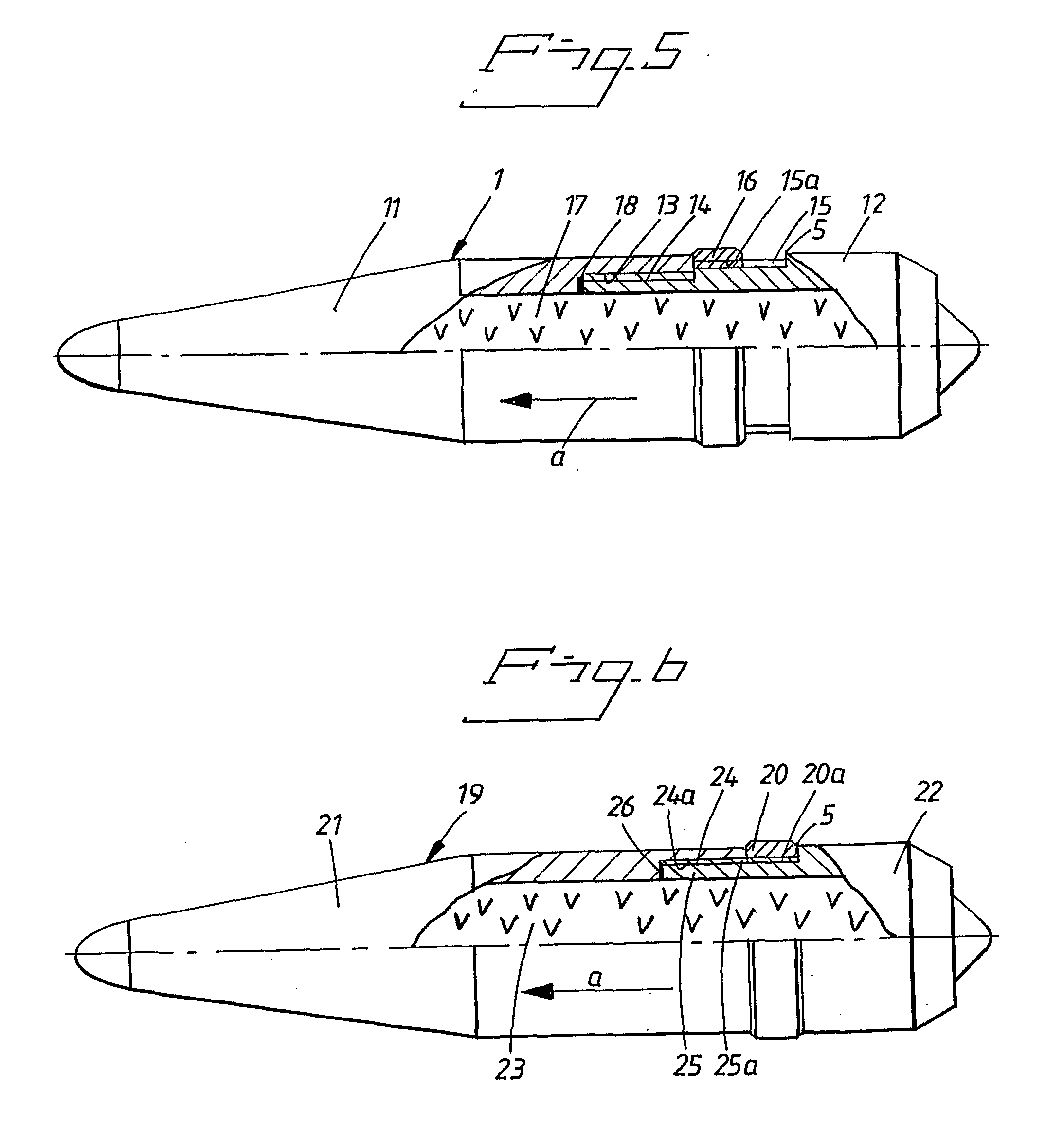

[0023]In its basic form, therefore, the invention means that manufacturing becomes less expensive, since there is no longer any need for high-pressure pressing of the band. This is achieved despite the fact that the method according to the invention necessarily involves manufacturing the artillery shells in two parts that are joined together. These two shell parts can in fact be readily manufactured on the same automatic machines previously used for manufacturing shells in one piece. Moreover, according to further developments of the invention it is possible, according to the same basic principle, to manufacture artillery projectiles which can alternatively be launched from a rifled

barrel with or without spin, whilst it is also possible, according to a new method, to launch spin-free projectiles from rifled barrels without the use of so-called slipping plastic bands which, as will be apparent from the following, has many disadvantages.

[0024]If it is intended to launch a fin-stabilized projectile from a rifled barrel without the barrel

rifling causing the projectile to spin, it is necessary in the prior art to use a projectile provided with a so-called slipping band. Basically the slipping band, which on projectiles intended for spin-free firing replaces the

copper band of the conventional spin-stabilized projectile, has approximately the same shape as the

copper band, but the slipping band is made from polyacetal or other plastic material. However, the slipping band is not quite the

ideal solution to the problem, even though its use has become very widespread. The slipping plastic band, for example, does not afford the same effective seal against the rifled inside of the barrel as a non-slipping copper band and it thereby tends to reduce the

muzzle velocity Vo of the projectile, and it is furthermore not uncommon to get so-called “blow by” with slipping plastic bands, which means that sufficient quantities of

propellant gases leak past the band to damage the forward part of the projectile, which can lead to serious problems in the case of so-called “intelligent ammunition”. Other disadvantages of the so-called slipping band include the fact that because it has to be made from a relatively soft material, up to the point of firing it is always very susceptible to external damage. In addition it is very tricky to design slipping plastic bands with the right slipping characteristics. The testing of new types of projectiles with slipping bands therefore always proves very costly. Finally the slipping bands are difficult to fit in that they easily acquire permanent deformations when fitting, in as much as the fitting normally involves pressing the closed band ring over a guide bead on the full-calibre shell or on the discarding

sabot in the case of the sub-calibre,

solid core projectile.

[0025]The present invention now provides a solution to the aforementioned problems, which means that in future it will also be possible to used

metal bands, for example copper bands, when firing non-

spinning projectiles from rifled barrels. The invention also means that, even at a

late stage right up to a point just prior to firing and without any actual conversion, it will be possible to adapt one and the same projectile from one which in a first variant or mode leaves a rifled barrel as a non-

spinning projectile, which, provided that it contains the necessary control functions from the outset could, after shedding the stabilizer fins, also be guided towards the intended target, to one which in its other variant, when fired from the same barrel, functions as an entirely conventional,

spinning projectile, without the constituent fins of the profile being allowed to fall off. The latter variant is therefore suitable over short ranges, for example, which do not allow for shedding of the fins and in which it is not possible to make use of control functions. The present invention therefore makes it possible to use one and the same shell type for two different types of target, each of which previously required a different type of shell.

Login to View More

Login to View More  Login to View More

Login to View More