Emission control system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

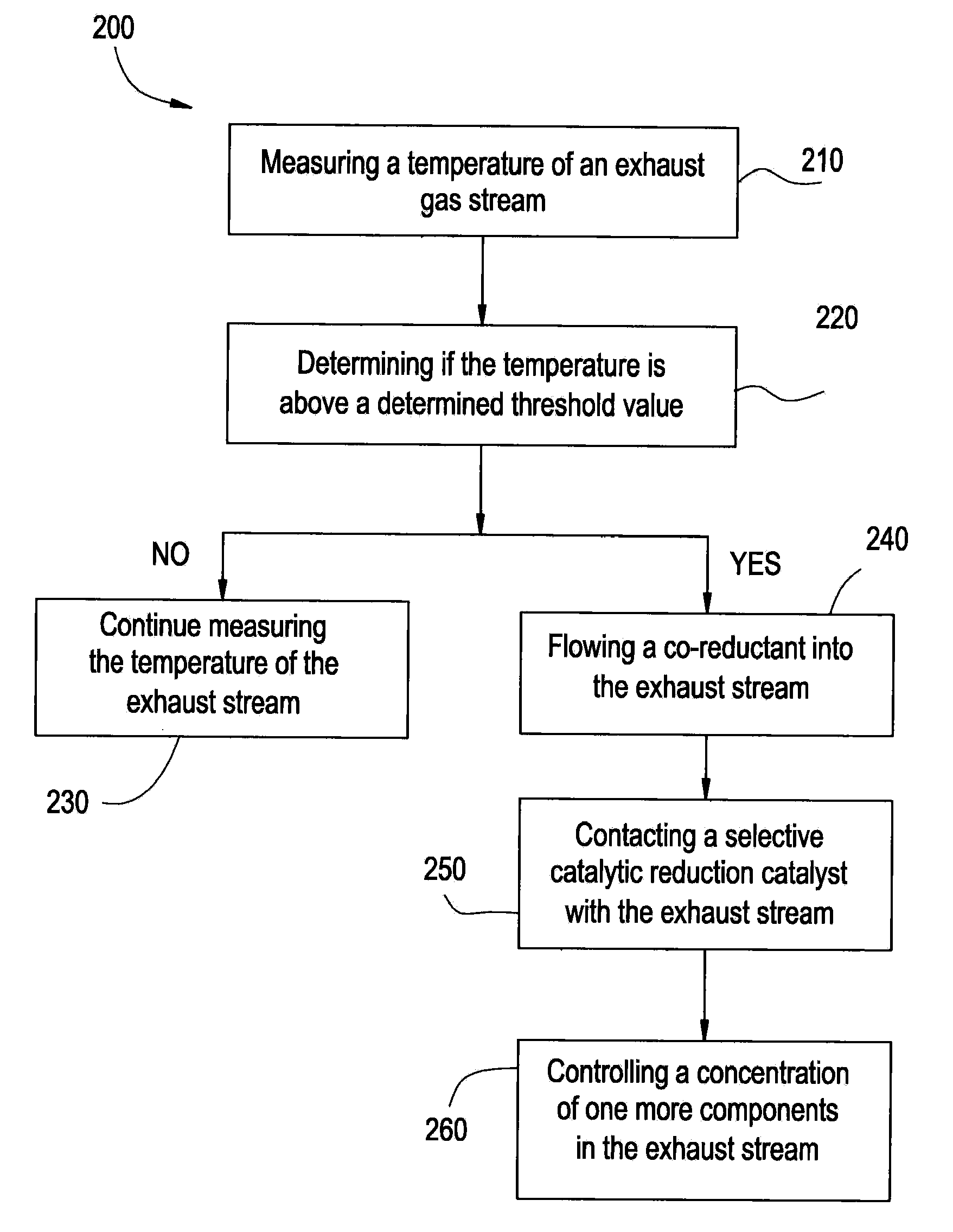

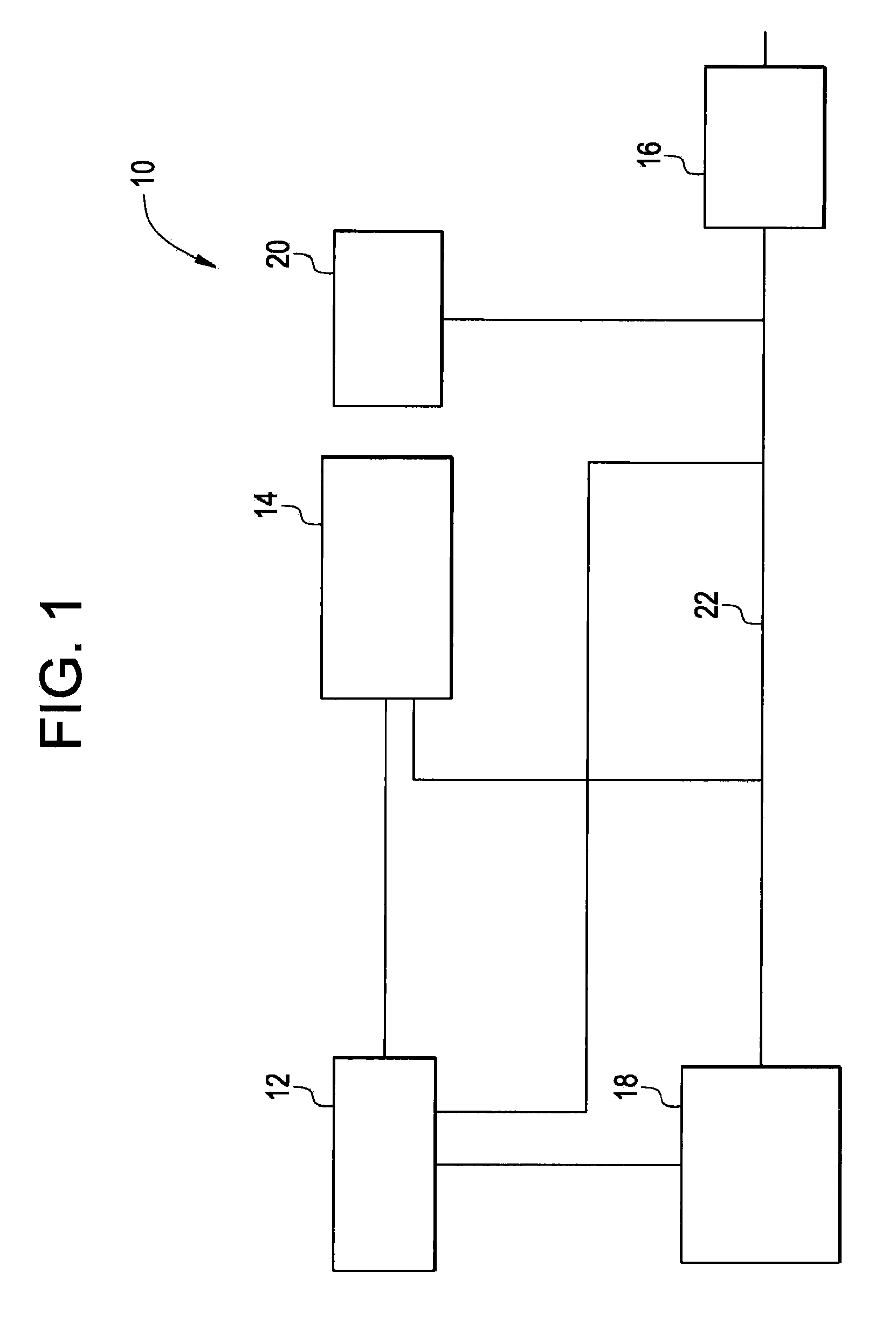

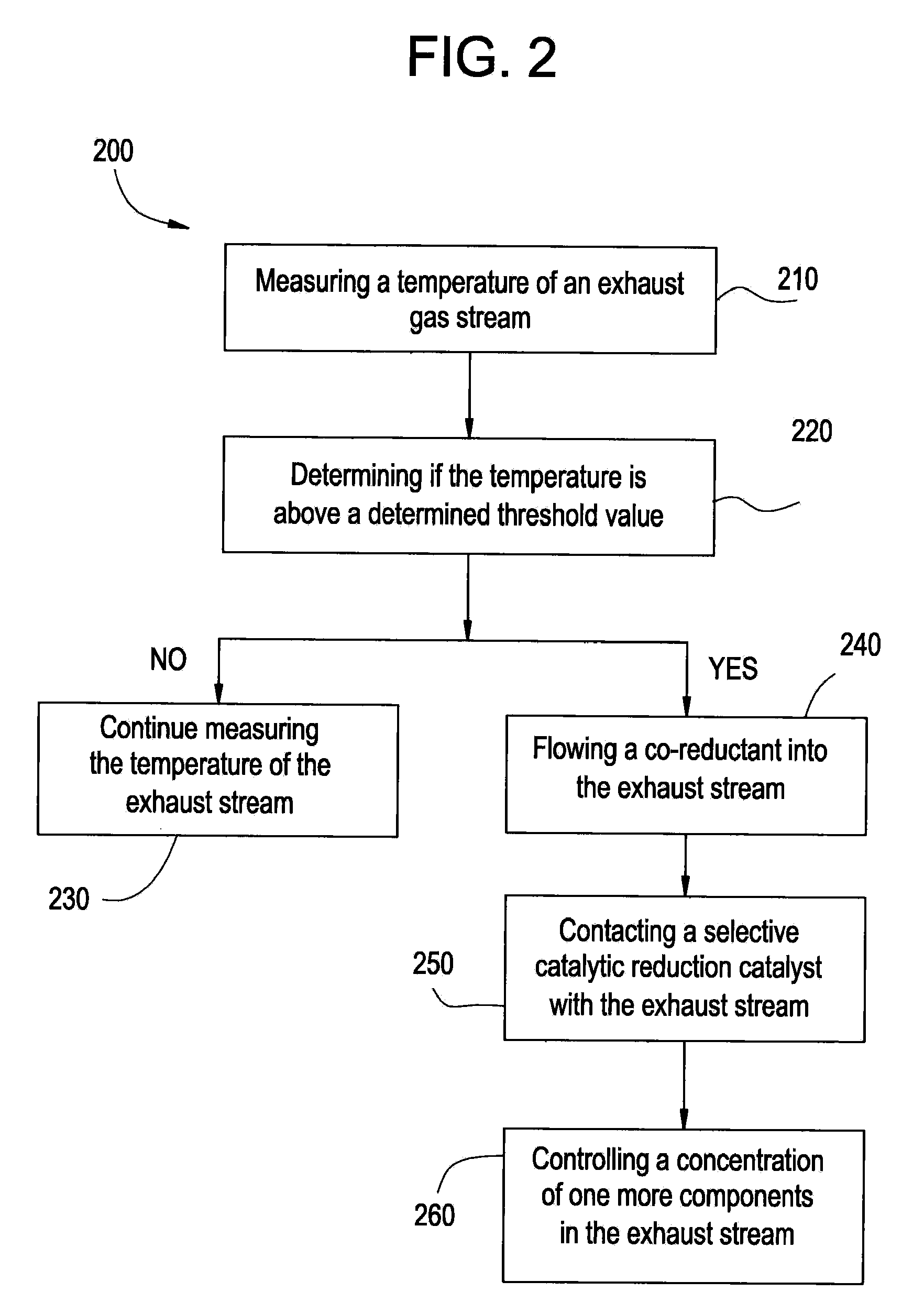

[0013]The present disclosure includes embodiments that relate to a system for controlling emissions. The disclosure includes embodiments that relate to a method for controlling emissions. A system or a method for controlling emissions may reduce the nitrogen oxides (NOx) emissions from the exhaust gas stream of a vehicle or a stationary source. Vehicles may include locomotives, marine vessels, off-highway vehicles, tractor-trailer rigs, and passenger vehicles. Emissions control refers to the ability to affect the compositional make up of an exhaust gas stream. As exhaust gas is a mixture of components, the reduction of one component almost invariably increases the presence of another component. For clarity of discussion, the chemical reduction of NOx is used as a non-limiting example of emission reduction insofar as the concentration of a determined species within the exhaust gas stream is controlled.

[0014]In one embodiment, the system may utilize a fuel source, as well as hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com