Rotation detector,wheel bearing equipped therewith and process for manufacturing the same

a technology of rotating detectors and wheel bearings, which is applied in the direction of magnetic sensor geometrical arrangements, instruments, mechanical apparatuses, etc., can solve the problems of inability to expect adhesion between the covering material and the component parts built therein, water proofing property problems, and the like, so as to improve durability, avoid damage to the sensor component parts, and improve water proofing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

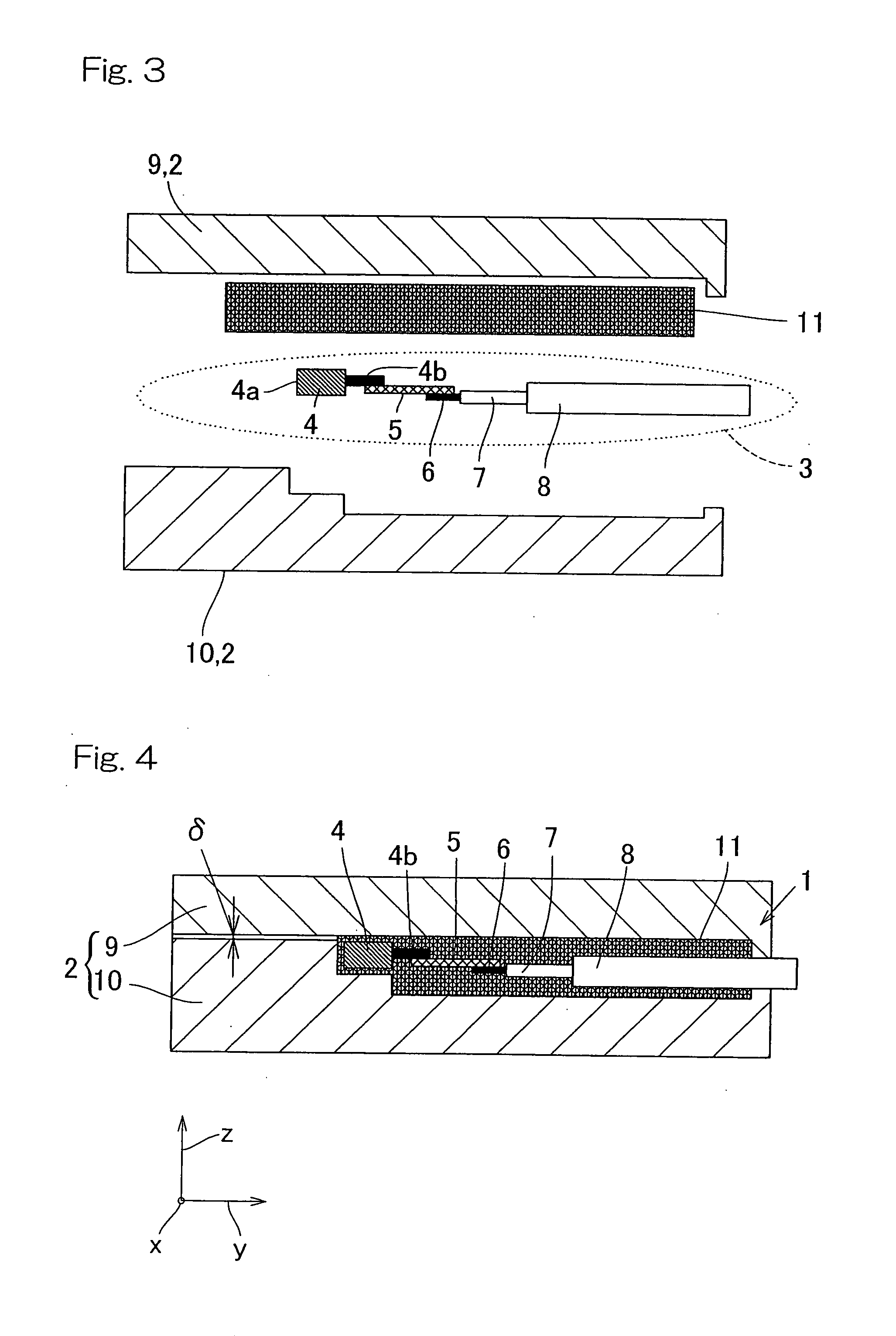

first embodiment

[0092]In the first embodiment described above, the upper mold 9 and the lower mold 10 are so structured as to form a predetermined minute gap δ between the upper mold 9 and the lower mold 10 in a condition in which the pressure is applied to a predetermined object to be pressed. By so designing, at the state in which the pressure is applied to the sensor assembly 3 forming an object to be pressed, it is possible to allow the excessive rubber material 11 to be discharged smoothly to the outside of the mold assembly 2. Accordingly, it is possible to avoid formation of shrinkage cavities inside the elastic member, which would otherwise result from the use of the rubber material 11 in a small quantity. It is possible to avoid such an inconvenience that if conversely the amount of the rubber material 11 is large, the rubber material 11 cannot be accommodated within the mold assembly 2 and the molding cannot therefore be accomplished satisfactorily.

[0093]According to the rotation detectin...

second embodiment

[0105]FIG. 5 illustrates a sectional view of the rotation detecting device according to the present invention. In FIG. 5, the fixing attachment 21 is made of a metallic material such as, for example, steel, aluminum, copper or brass, of a kind having an affinity to bond with the rubber material. In consideration of the corrosion resistance, the use of an austenitic stainless steel, a steel having been surface treated with zinc base alloy or an alumite treated aluminum is preferred. It is, however, to be noted that the metallic material that can be employed is not necessarily limited thereto. The fixing attachment 21 has a function of positioning the sensor 4 and the peripheral component parts. The fixing attachment 21 includes, mainly, a recessed portion 22 representing a concaved shape as viewed from side, a cable fixing portion 23 formed integrally with one side edge of the recessed portion 22 and a sensor fitting portion 24 formed integrally with the opposite side edge of the rec...

third embodiment

[0118]FIG. 7 is a sectional view showing the rotation detecting device according to the Referring to FIG. 7, the connecting member 25 has a rear end face fixed to the first wall area 22b at a lower portion thereof extending from a junction with one surface of the bottom area 22a to the supported cable insulating sheathes 7.

[0119]The connecting member 25 has a front end face, a lower half of which is fixed to the one surface portion of the second wall area 22c. The other surface portion of the second wall area 22c is exposed to the outside. A bottom face of the connecting member 25 is fixed to the one surface of the bottom area 22a of the recessed portion 22. The elastic member 11 A is fixed on one surface portion of the sensor fitting portion 24 and the opposite surface portion of the sensor fitting portion 24 is exposed to the outside. As described in connection with the second embodiment, the fixing attachment 21 serves to position the sensor 4 and the peripheral component parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com