Ultra-compact, linear, solar-thermal steam generator

a solar thermal and generator technology, applied in the direction of solar heat generation, solar heat systems, lighting and heating apparatus, etc., can solve the problems of large field required for a given thermal output, less effective, and high convection heat loss of absorbers, so as to achieve the effect of optimizing their position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

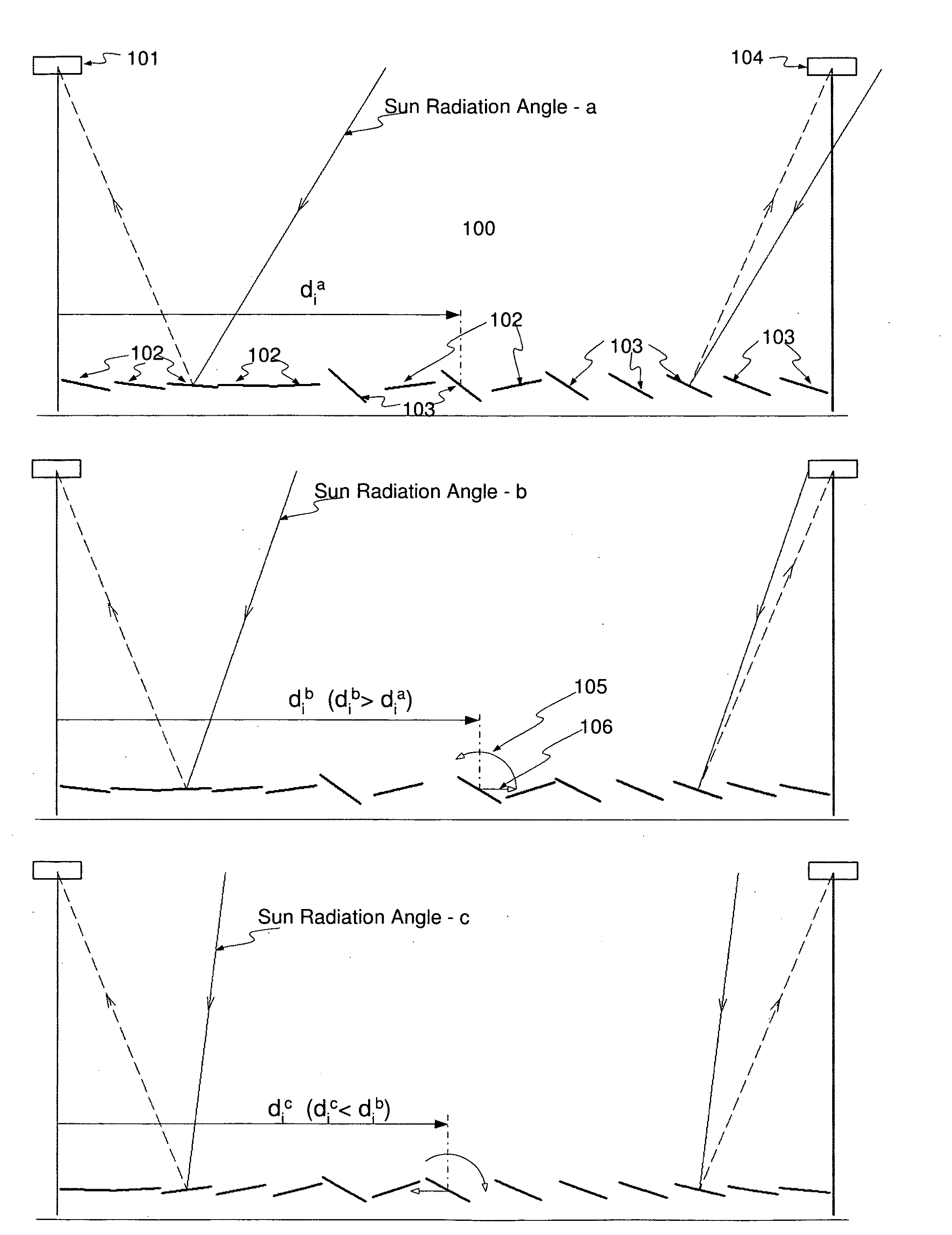

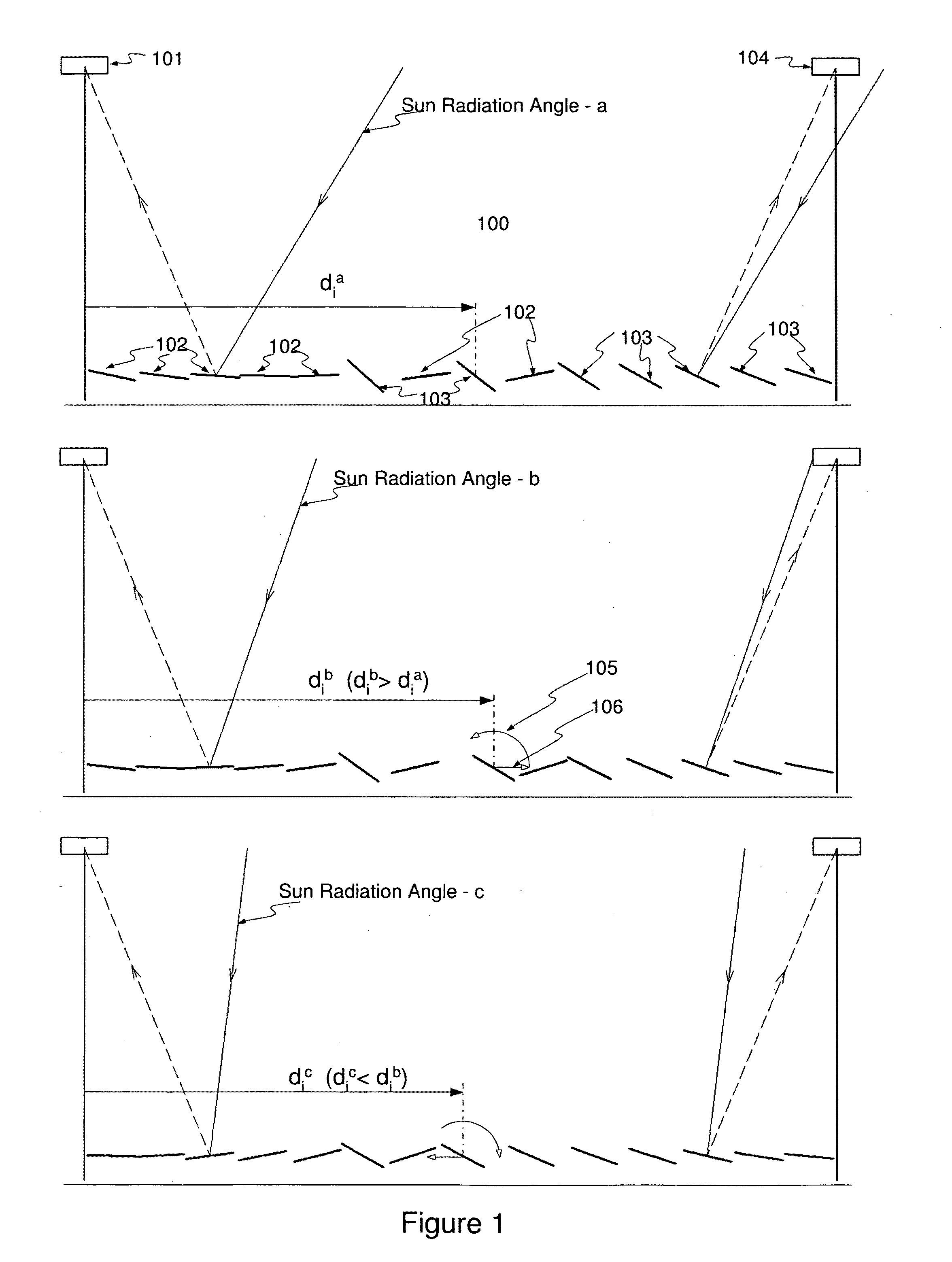

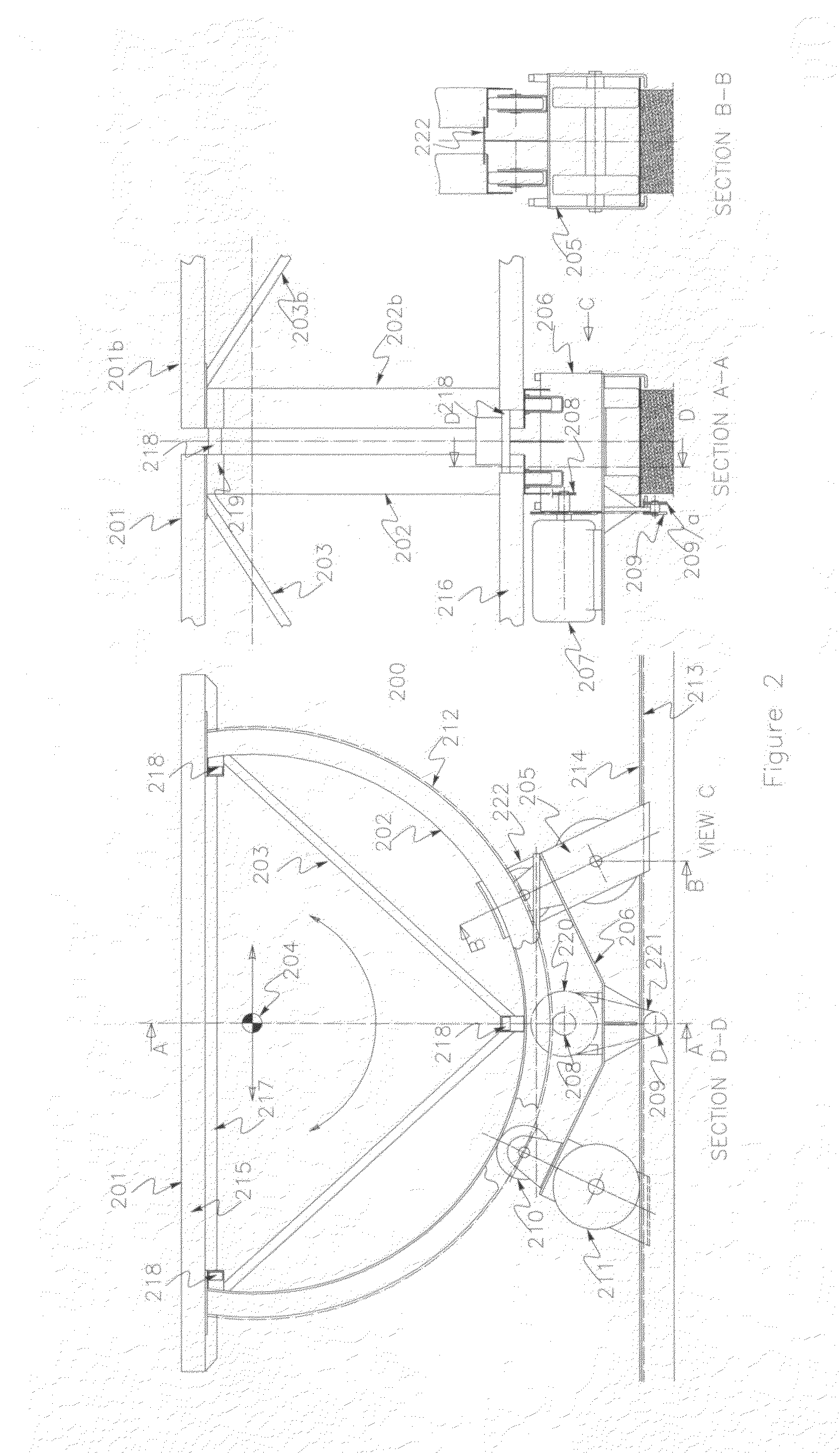

[0017]Referring now to the drawings, in which like numerals indicate like elements throughout the several views, FIG. 1 shows a schematic view of Basic Field Unit 100, comprised of multiple rows of reflectors 102 and 103, between two adjacent collectors 101 and 104 elevated on columns, located above the reflectors. A multitude of BFUs aligned parallel with the reflector rows, and connected to one common steam generation loop comprises one Steam Generation Module (SGM). Multitude of SGMs comprises the Solar Thermal Steam Generation (STSG) Field.

[0018]Based on optimization strategies, the reflectors may target either of the two collectors on the edges of the BFU. Pending on which side of the targeted collector the reflector is, compared to Sun's position; there are Pro-Solar 102 and Contra-Solar 103 reflectors. The Pro-Solar ones are on the same side of the collector as the Sun. The Contra-Solar ones are on the opposite side of the collector compared to the Sun. Similarly the collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com