Water production system and method with auxiliary refrigeration cycle

a technology of water production system and refrigeration cycle, applied in the direction of defrosting, domestic cooling apparatus, application, etc., can solve the problems of water production system, condensation is considered undesirable, and atmospheric water vapor is essentially untapped sour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

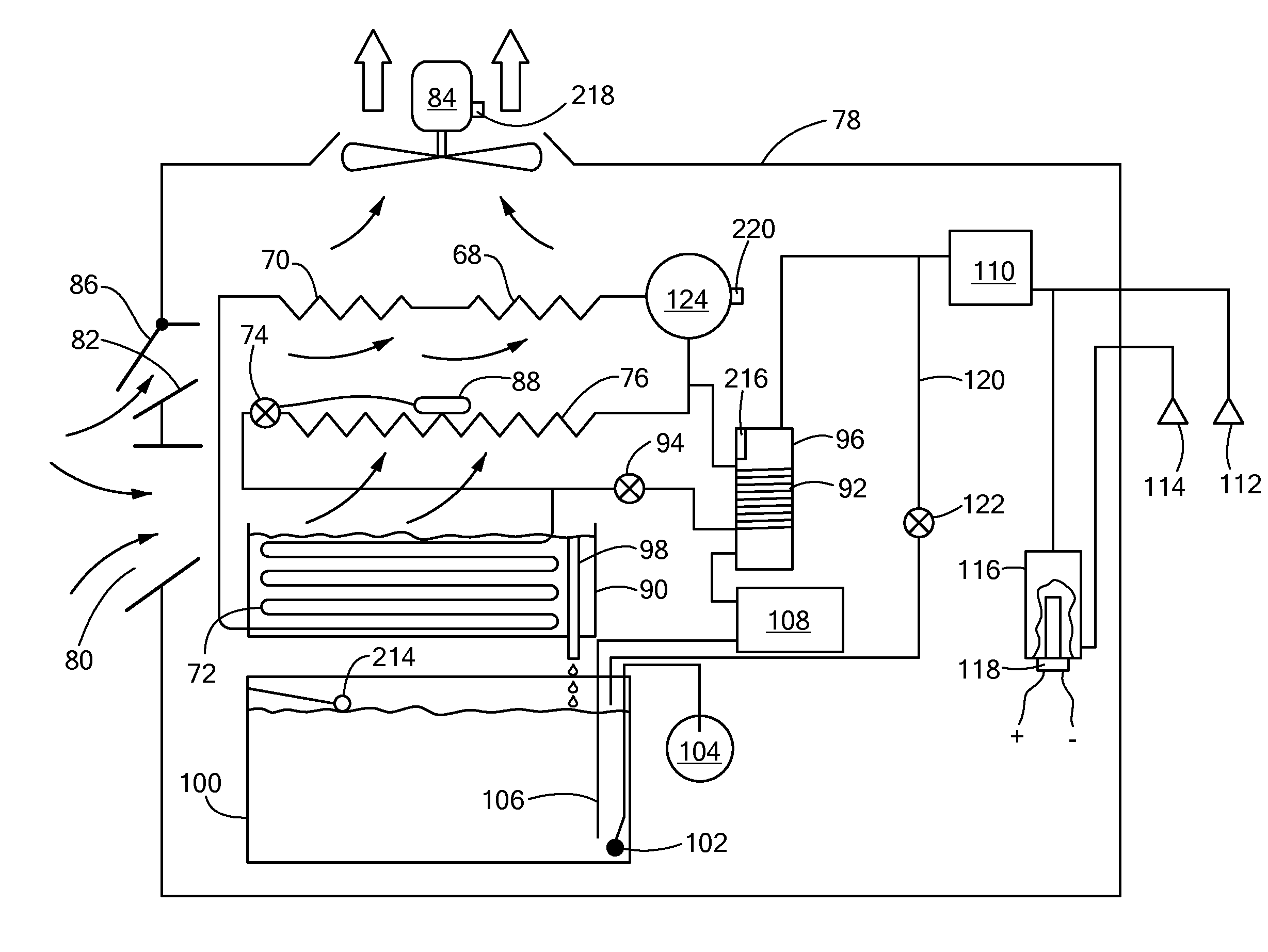

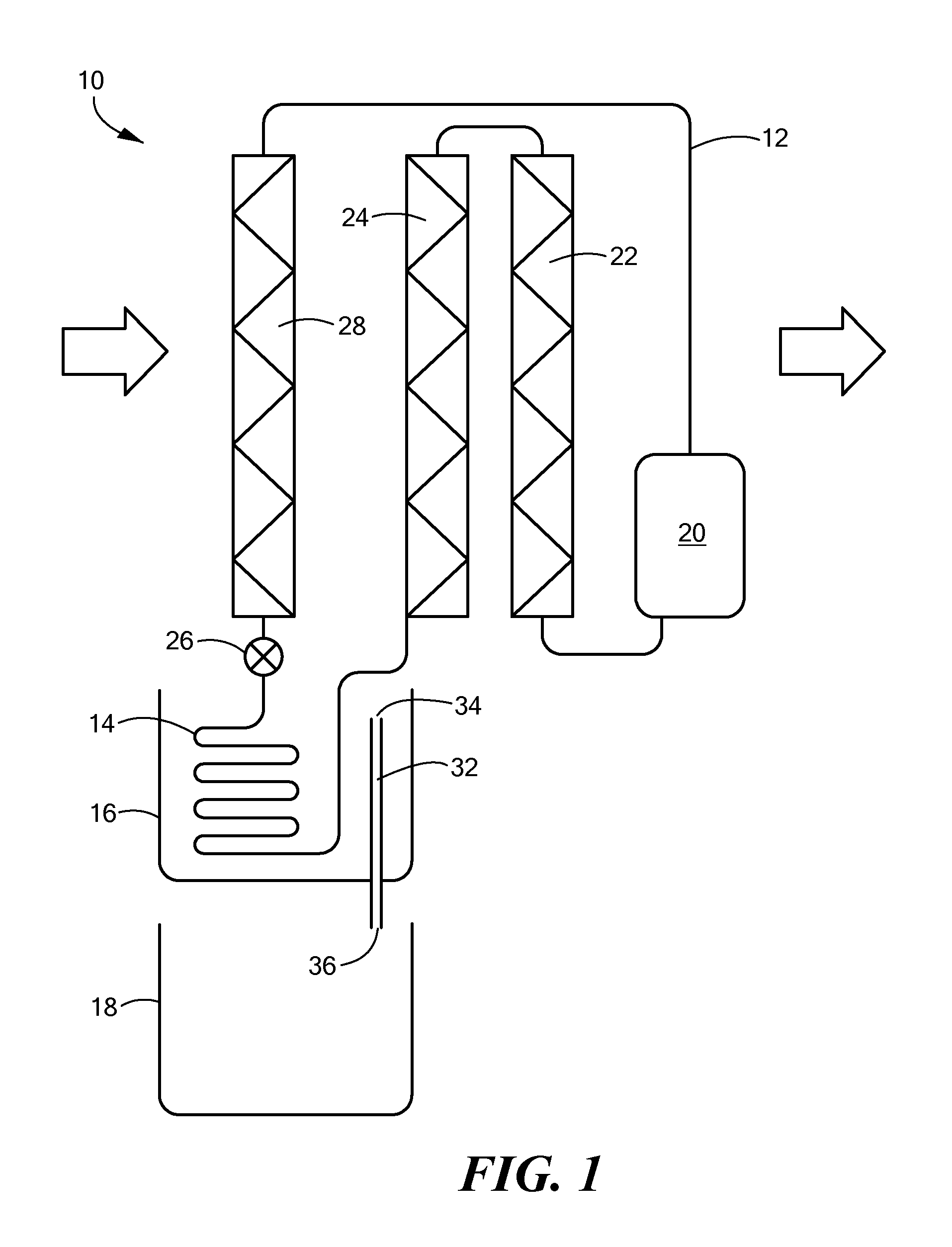

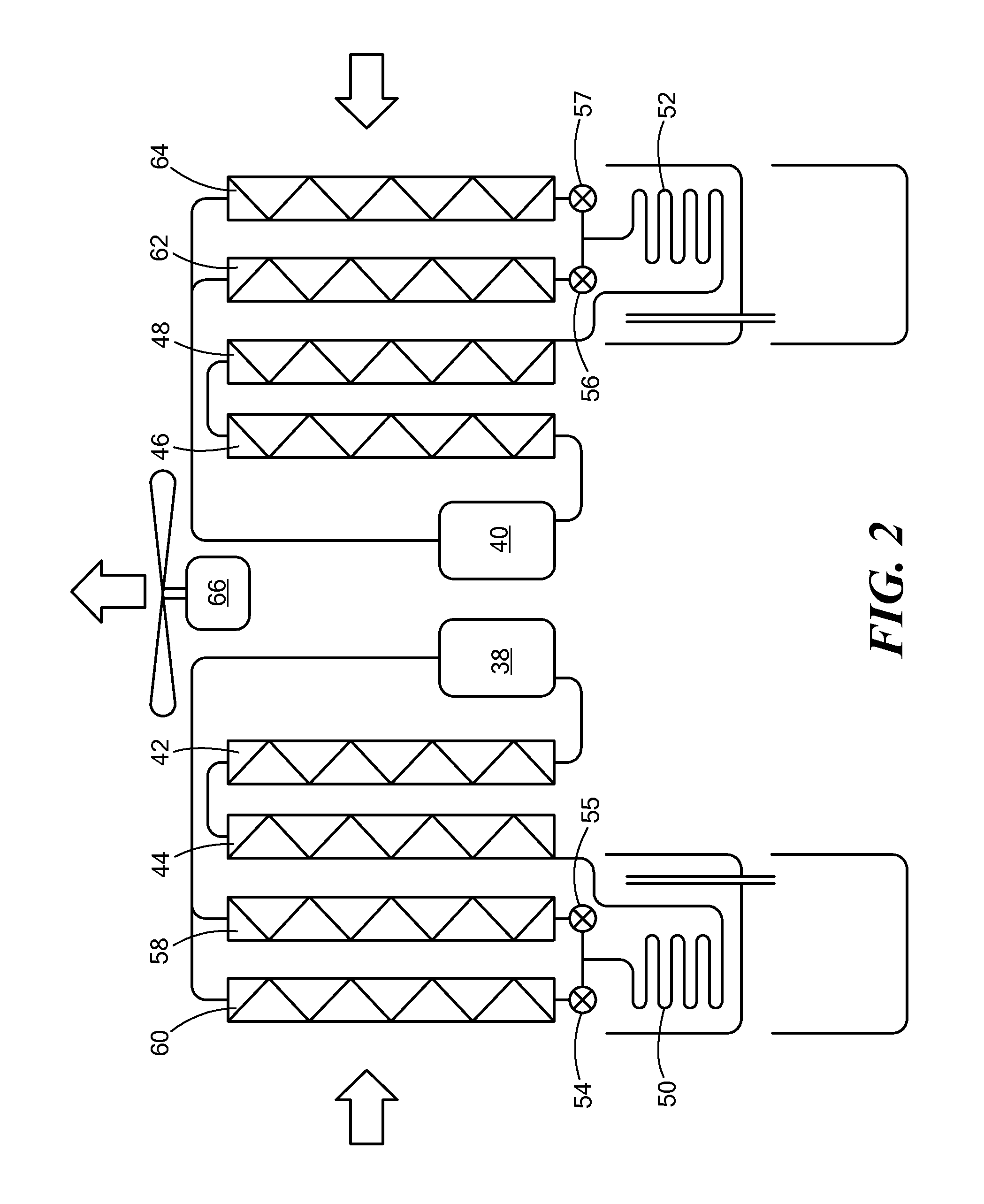

[0032]The present invention advantageously provides an improved system and method for extracting water from water vapor, for example from the atmosphere. The water production system of the present invention may have various sizes, arrangements and features.

[0033]Some aspects of the present invention relate to combinations of components and method steps for implementing systems and methods to improve the efficiency and operation of water production systems. Accordingly, some components have been represented where appropriate by conventional symbols in the drawings, showing only those specific details that are pertinent to understanding the embodiments of the present invention, so as to avoid details that will be readily apparent to those of ordinary skill in the art having the benefit of this description.

[0034]Relational terms, such as “first” and “second,”“top” and “bottom,” and the like, may be used solely to distinguish one entity or element from another entity or element, without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com