Modular Shower Cabin For Aircrafts

a shower cabin and module technology, applied in the field of modules for aircraft shower cabins, can solve the problems of high cost, large effort, and inability to individually replace, and achieve the effect of reducing the manufacturing cost of the shower cabin and being easy to access for being repaired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The indications of location and direction in the following description of the modular shower cabins always relate to a shower cabin in the upright position.

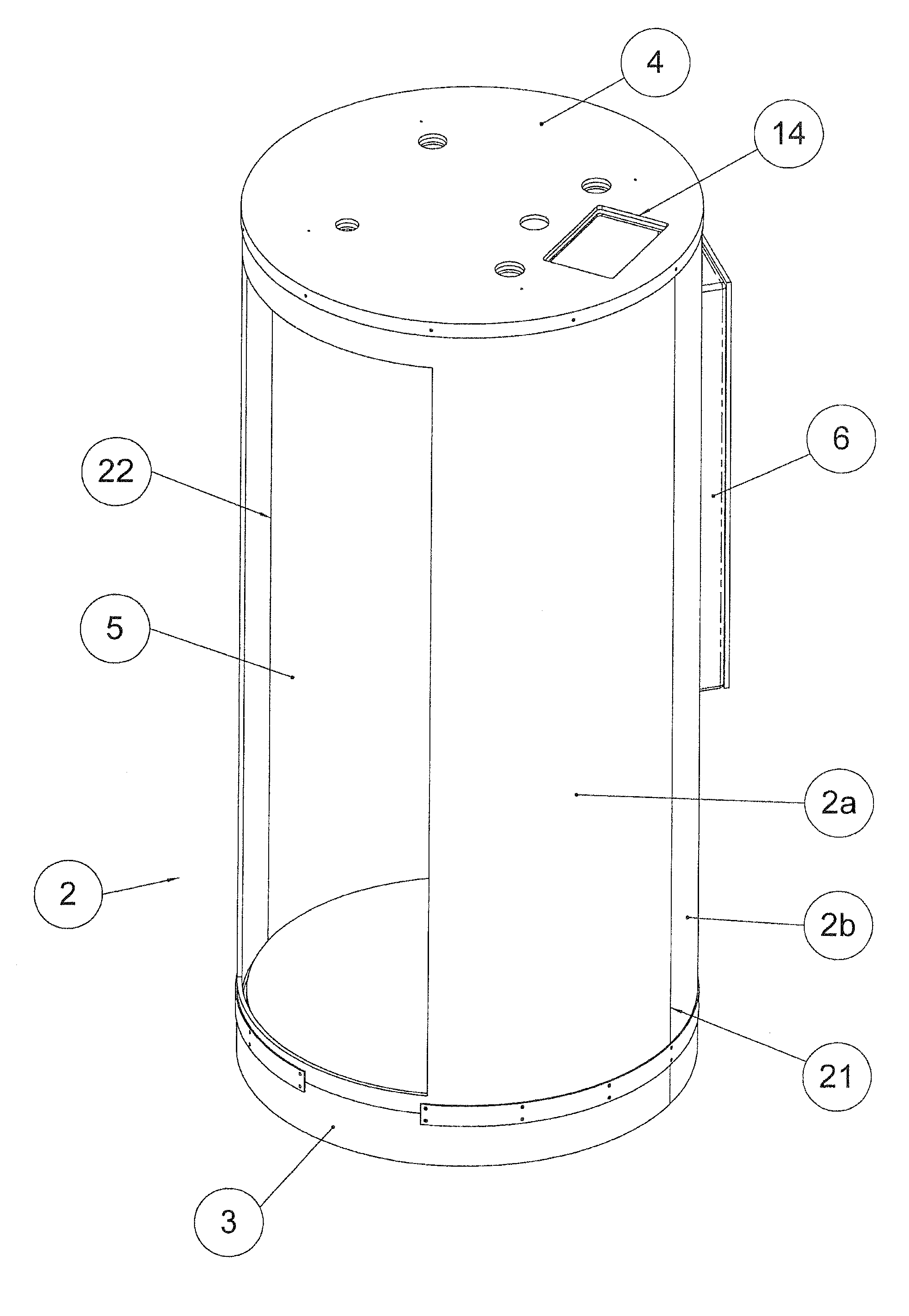

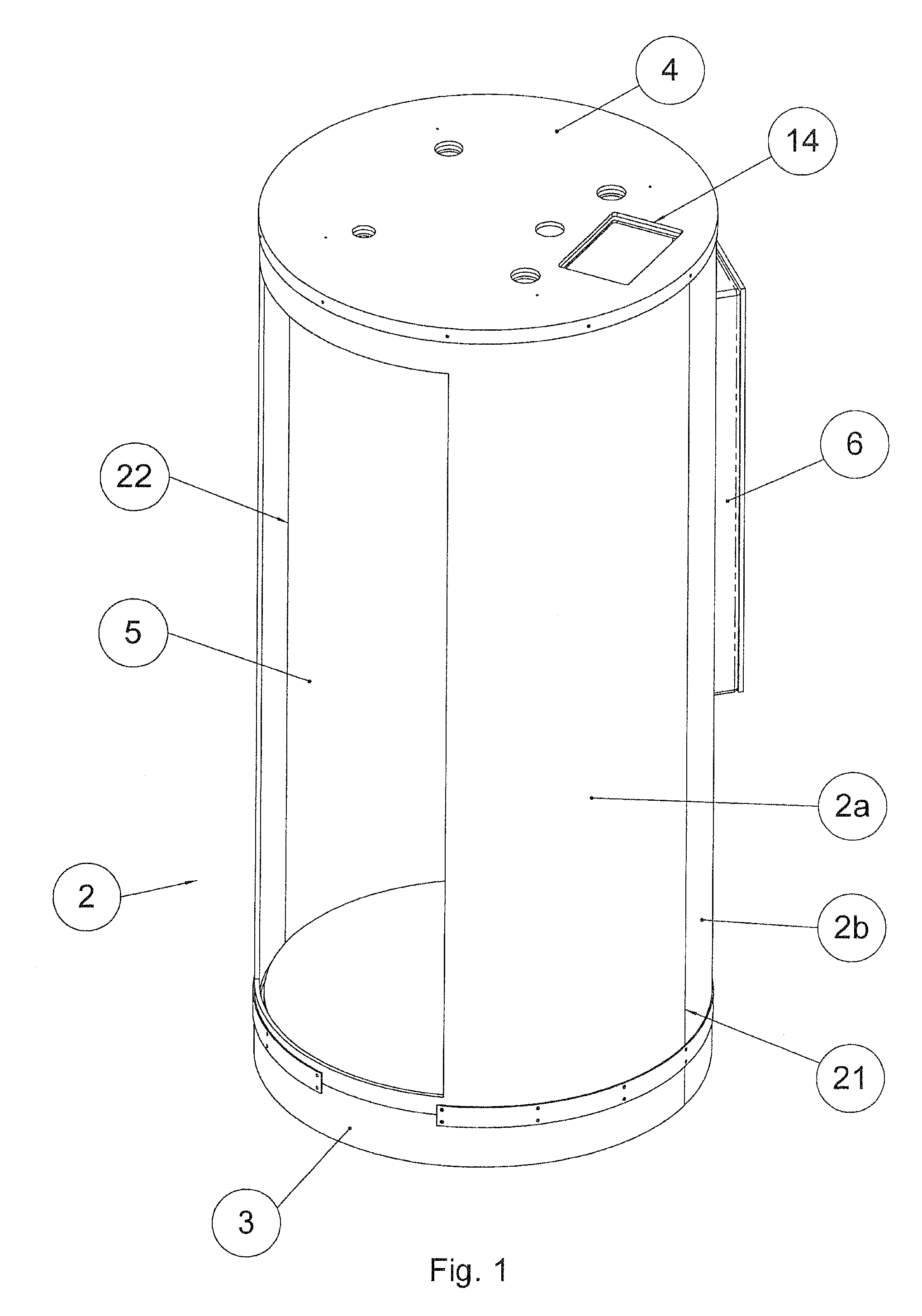

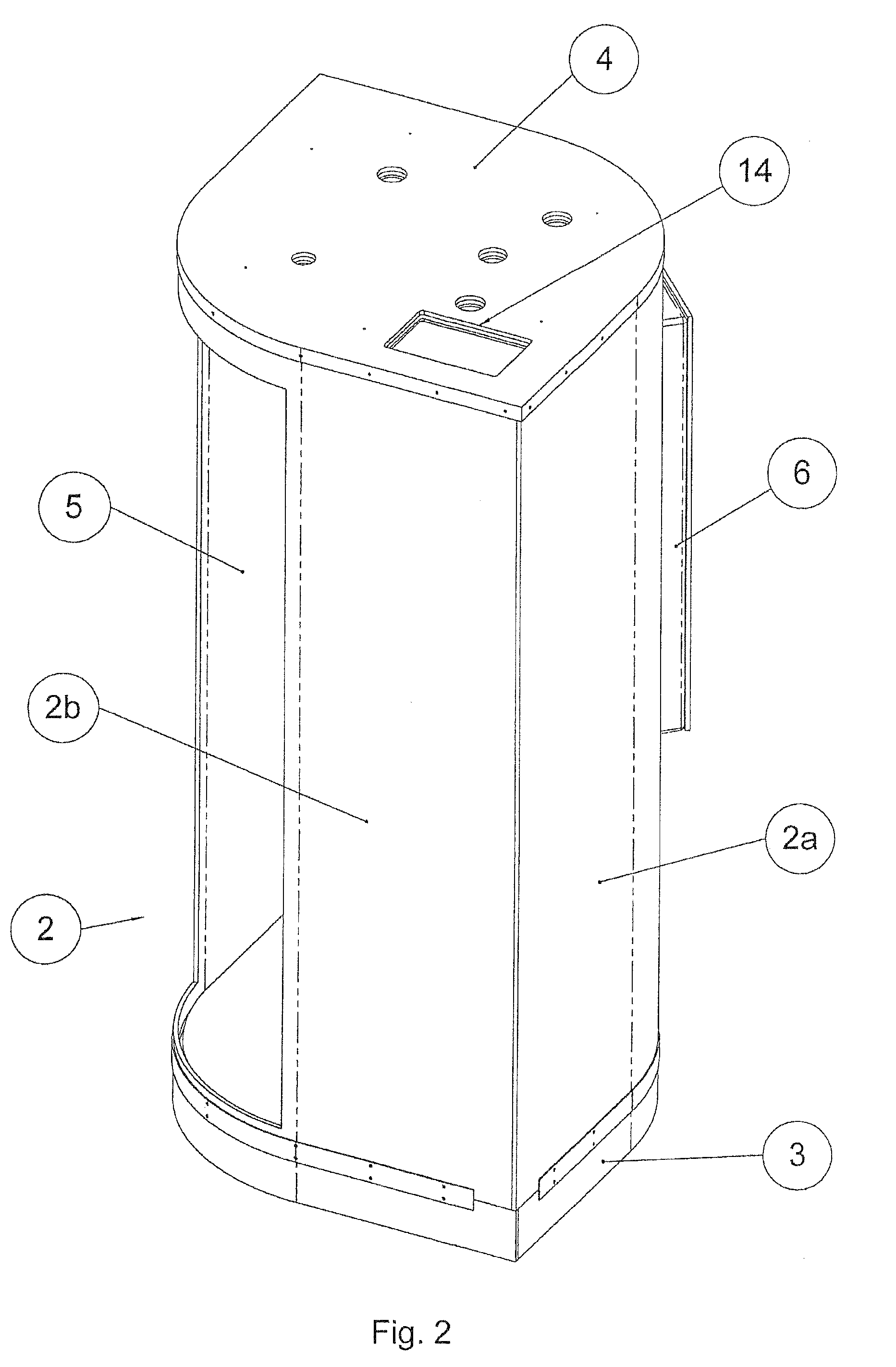

[0033]First of all, FIG. 1 shows a modular shower cabin comprising a barrel-shaped center portion 2. The barrel-shaped center portion 2 is limited towards the top by the ceiling portion 4 and towards the bottom by the bottom portion 3, and is formed by two structural components 2a and 2b having been joined together. The structural components 2a and 2b are designed to have the shape of a divided circle and are joined together at their vertical side edges 21 and 22 so that the cross-section of a full circle takes shape, as can also be seen in FIG. 6 in the viewing direction from the bottom to the bottom portion 3 with the drain 15 located in the center. A recess 5 is provided in the structural component 2a, which recess forms the entrance area and due to the design of the shower cabin according to the invention now is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com