Blower, housing and wind wheel thereof

a technology of wind turbine and housing, which is applied in the direction of wind turbine with perpendicular air flow, waterborne vessels, machines/engines, etc., can solve the problems of increasing development investment, increasing production cost and manufacturing difficulty, and high cost of aluminum-coated or galvanized steel plates, etc., to achieve short development period, reduce production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

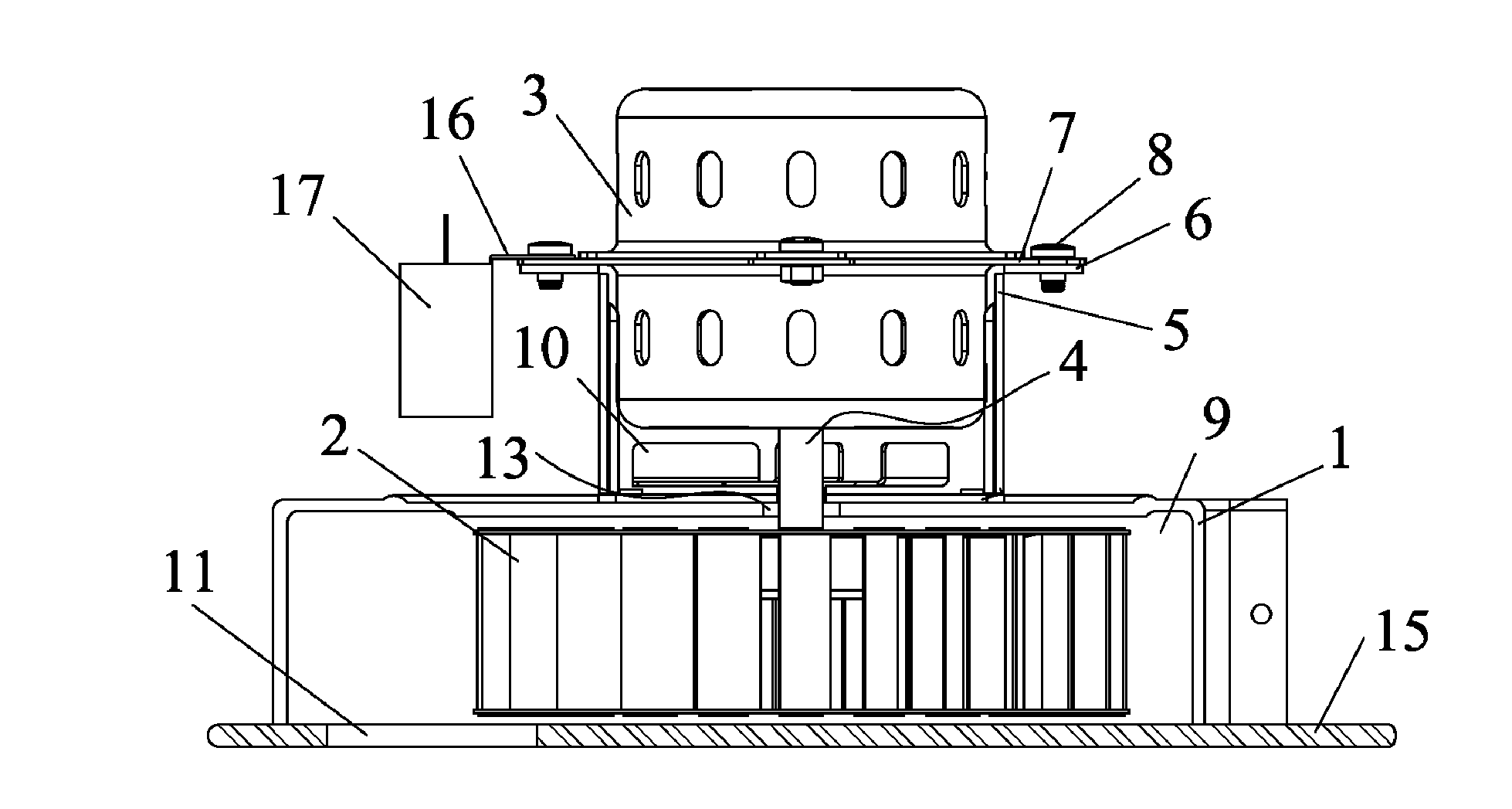

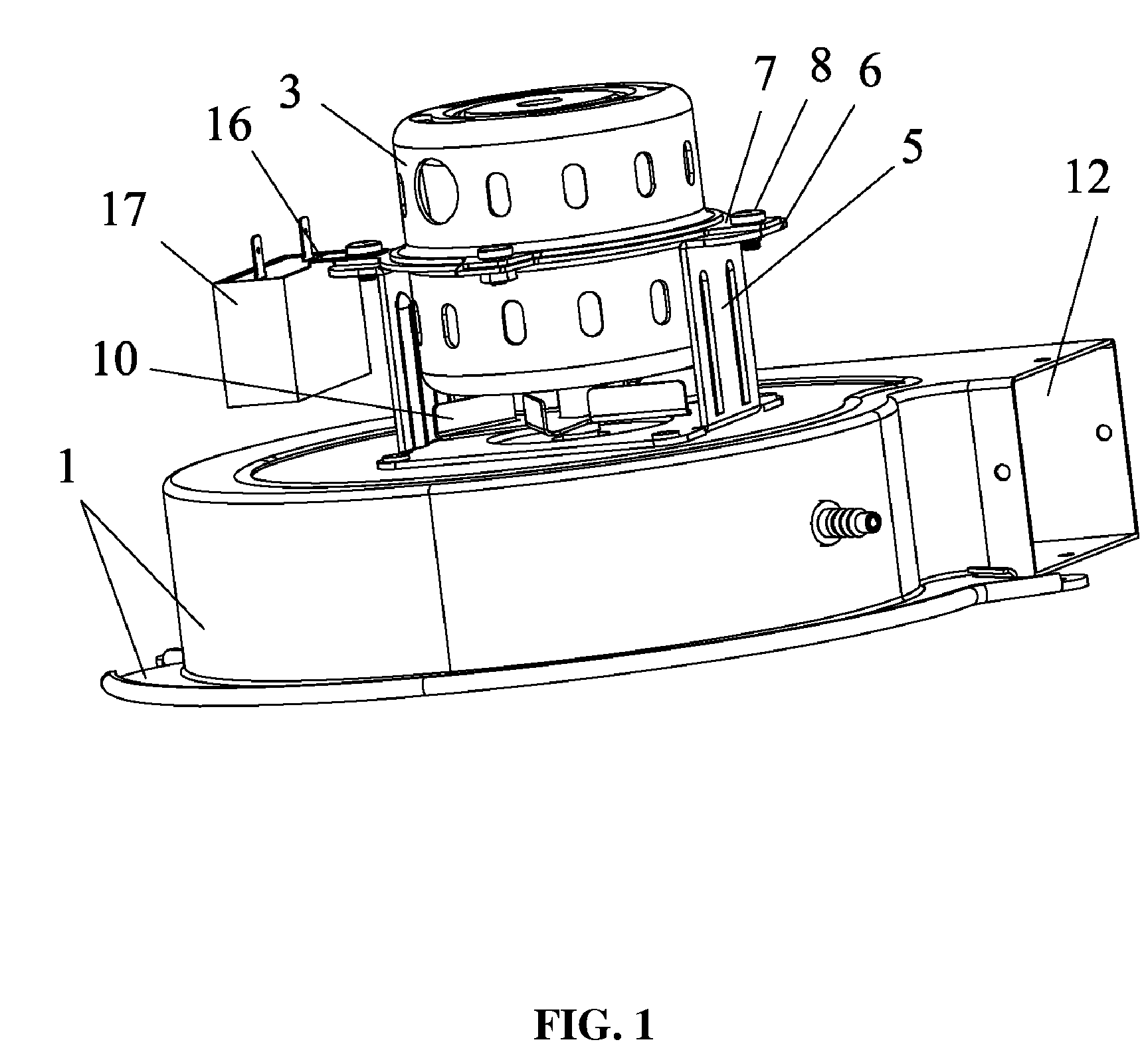

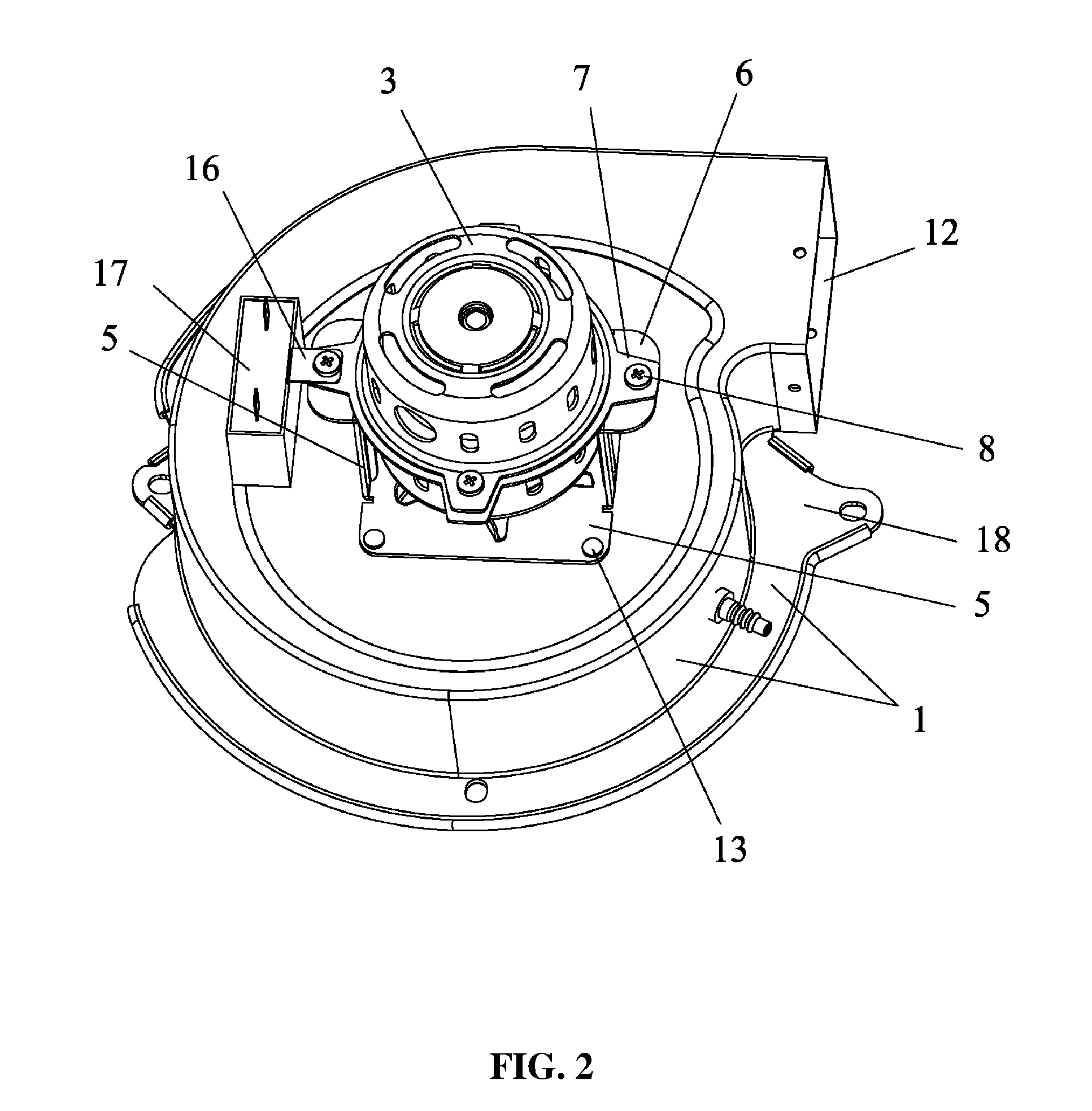

[0035]As shown in FIGS. 1-4, blower of the invention comprises a housing 1, a wind wheel 2, a motor 3, an air inlet 11, and an air outlet 12.

[0036]The housing 1 comprises a cavity 9, a body 14 and a bottom plate 15.

[0037]The housing 1 and the wind wheel 2 are made of steel plates, and enamel materials are coated on surfaces of the steel plates. In another embodiment, the wind wheel 2 is made of BMC resin.

[0038]The wind wheel 2 is disposed in the cavity 9 of the housing 1.

[0039]A hole is disposed at the top of the housing 1.

[0040]The motor 3 is disposed at the top of the housing 1 via a U-shaped supporter 5 and has a rotating shaft 4, and the rotating shaft 4 passes through the hole and is connected to the wind wheel 2 in the housing 1.

[0041]A bottom portion of the U-shaped supporter 5 is connected to the housing 1 via a rivet 13.

[0042]A flange 18 is extended from the cavity 9 and connected to the edge of the bottom plate 15.

[0043]A cooling fan 10 is disposed on the rotating shaft 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com