Tobacco Smoke Filter and Methods of Making the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0065 Filter Manufacture

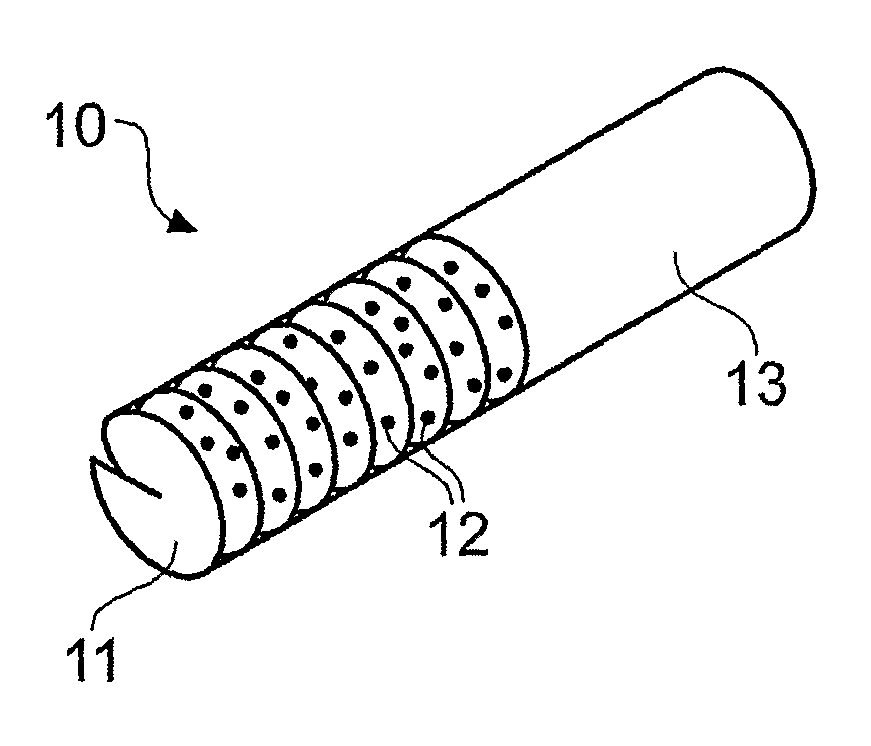

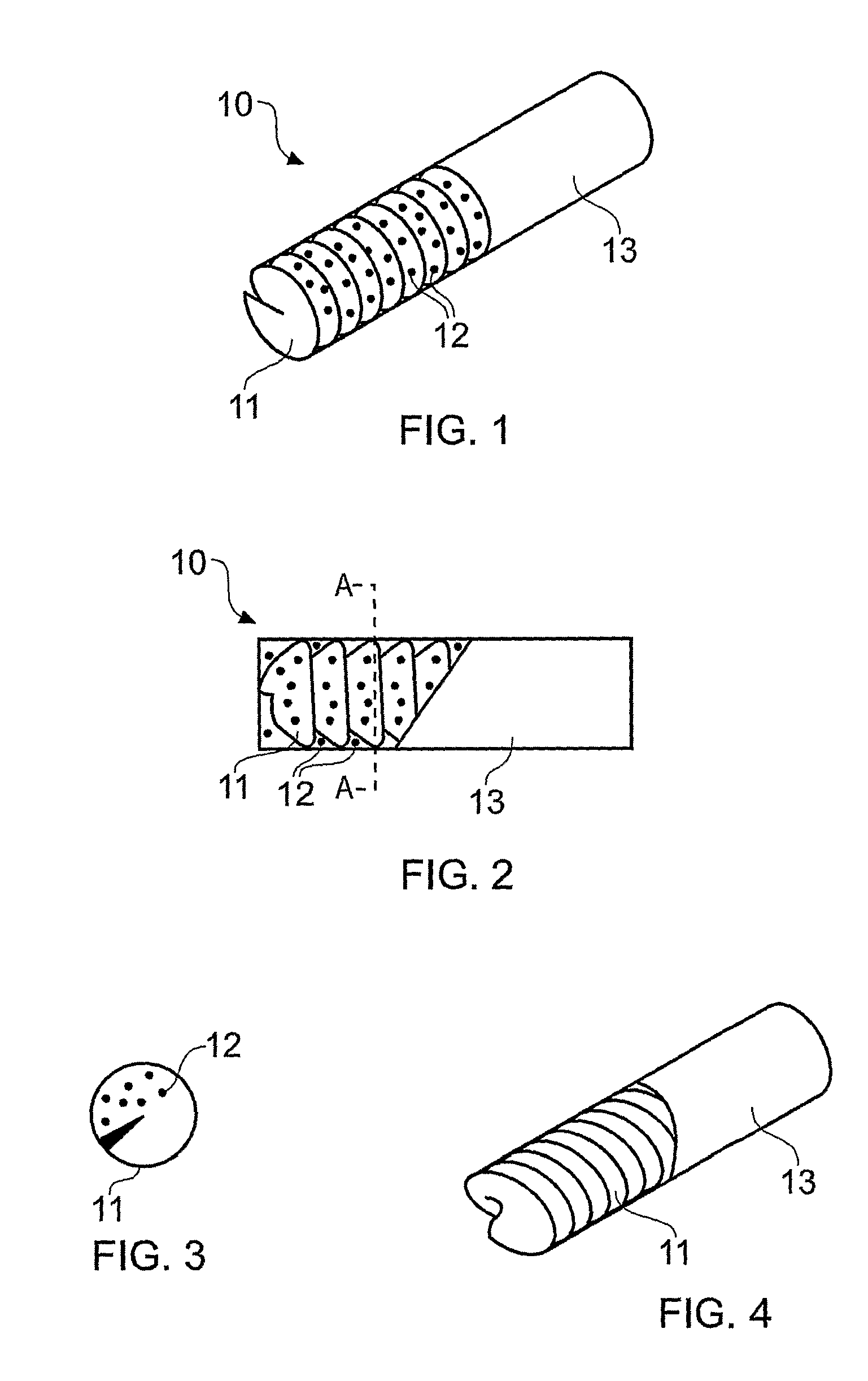

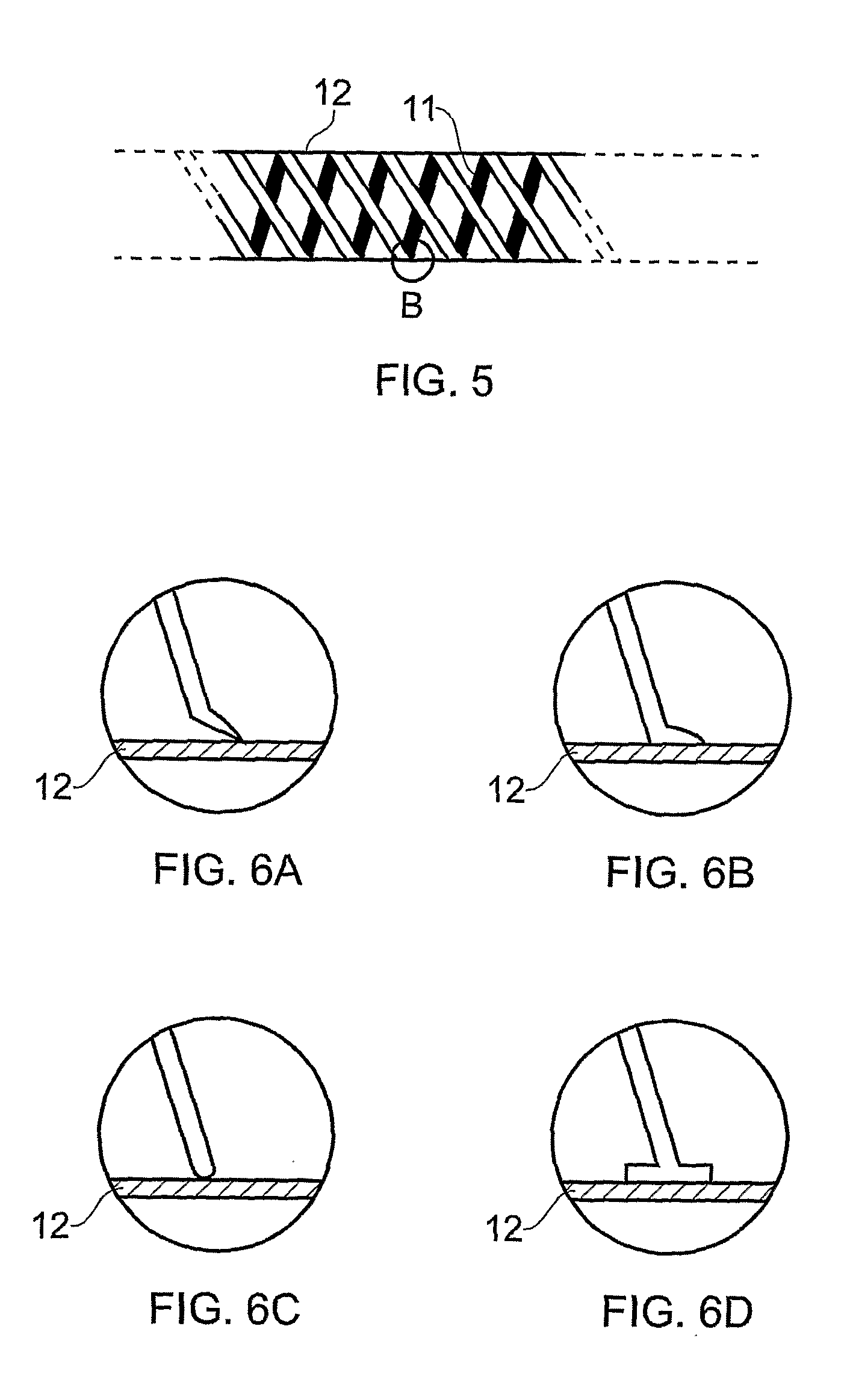

[0066]Activated carbon is moulded into a helical shape approximately 6 mm in diameter. An average pitch and low porosity, i.e., low permeability, are used. The carbon is cut into lengths of approximately 20 mm. Units of standard cellulose acetate tow approximately 6 mm in diameter and approximately 10 mm long are provided and arranged in alternating fashion with lengths of carbon helix.

[0067]The intra helical space of the carbon helix is provided with a mixture of flavourant and adsorbent before the length of helix / cellulose acetate tow is wrapped with an approximately 0.5 mm thick layer of cellulose acetate about its circumference. Plug wrap may optionally be provided around the cellulose acetate layer as known in the art.

[0068]This provides a length of filter material which may be cut along the middle of the approximately 10 mm lengths of cellulose acetate tow to provide a plurality of filter units each approximately 30 mm in length and each comprising an a...

example 2

[0070 Cigarette Manufacture

[0071]A resin commonly used in tobacco smoke filters is extruded through a die to produce a tight helical shape approximately 7 mm in diameter and 10 meters long. The shape is fed into a machine which applies suction or vacuum, for example a suction garniture, to pack fibres of cellulose acetate around the helix. The packed helix is wrapped in plug wrap and cured on a drying garniture. The cured filter is cut to 60 mm lengths which are provided to a cigarette making machine.

[0072]The cigarette making machine uses the filter to produce cigarettes according to known methods. In brief, two tobacco rods are positioned at either end of the filter and, once secured, the filter is cut at the middle. An optional end segment, for example, a pad of cellulose acetate, is added at the mouth end of the cigarette to mask the helical core unit. The resultant product is a cigarette incorporating a novel tobacco smoke filter according to the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com