Process for dewatering an aqueous organic solution

a technology of organic solution and process, applied in the direction of filtration separation, separation process, membrane, etc., can solve the problem of high energy consumption of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0047]To estimate the energy savings of the invention, a hypothetical reservoir is assumed to be an open evaporation pond located in an area with plenty of sunshine and the following average climatic conditions:

Relative Humidity (%)52.6Average Temperature (° C.)18.6Average Wind speed (m / s)2.84

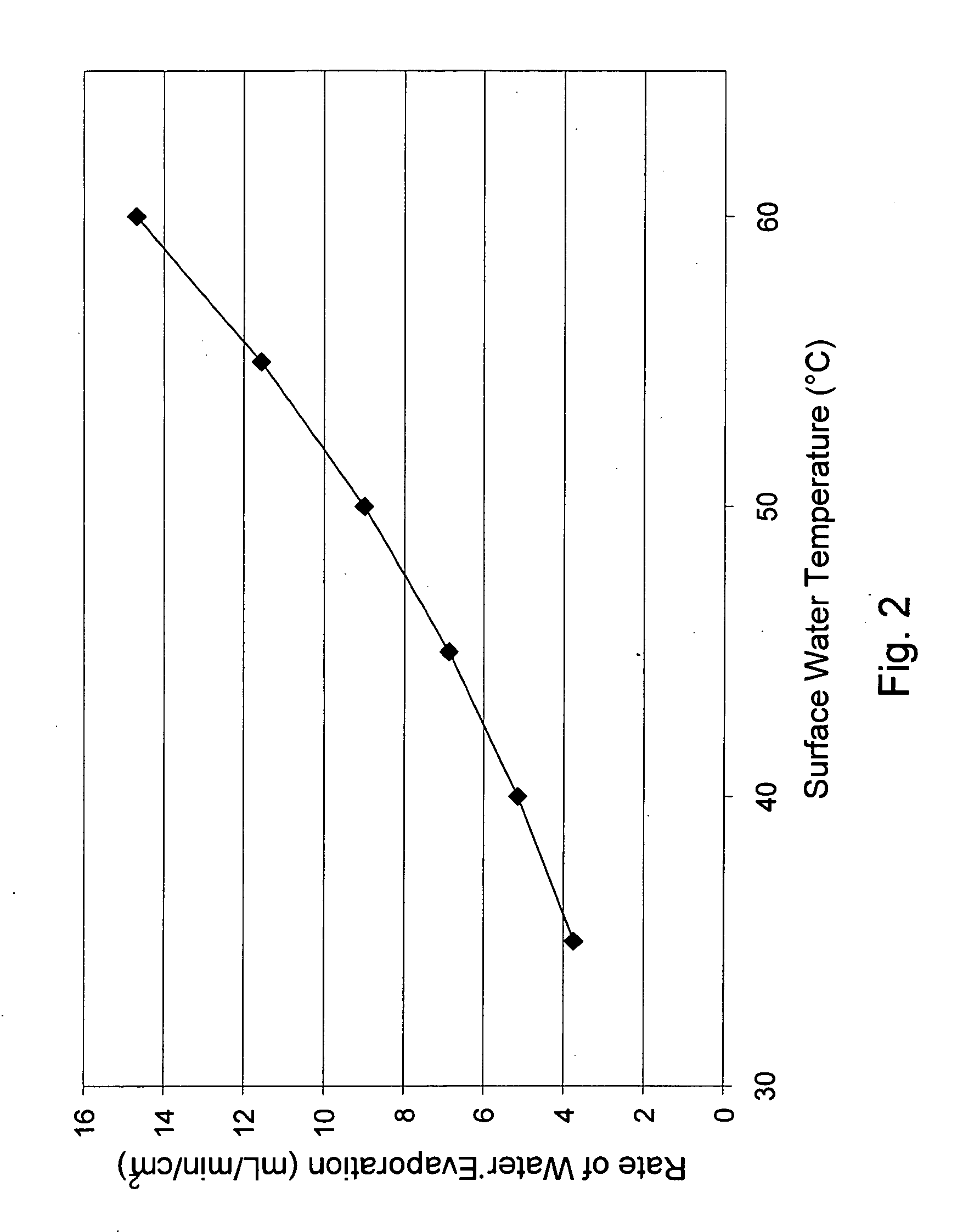

[0048]The draw solution is a 20 wt % solution of magnesium chloride in water. Absorbed solar energy leads to a rise in the temperature of the draw solution. FIG. 2 shows the change in evaporation rate with change in temperature on the water surface. FIG. 2 indicates that by allowing solar heating to raise the temperature of water surface to 50° C., approximately 540 mL / hr / cm2 of water can be removed. The pond area was determined by the surface area needed to evaporate water sufficient to attain draw solution concentration of 5M MgCl2 in water.

[0049]A cellulose triacetate membrane is used in the osmosis process. The membrane is assumed to be impermeable to ethanol. A water / ethanol separation fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com