Combined multi-stream heat exchanger and conditioner/control unit

a multi-stream heat exchanger and control unit technology, applied in lighting and heating apparatus, process and machine control, instruments, etc., can solve the problems of increasing maintenance costs and damage to major engine components, and achieve the effect of reducing the heating value of a natural gas stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

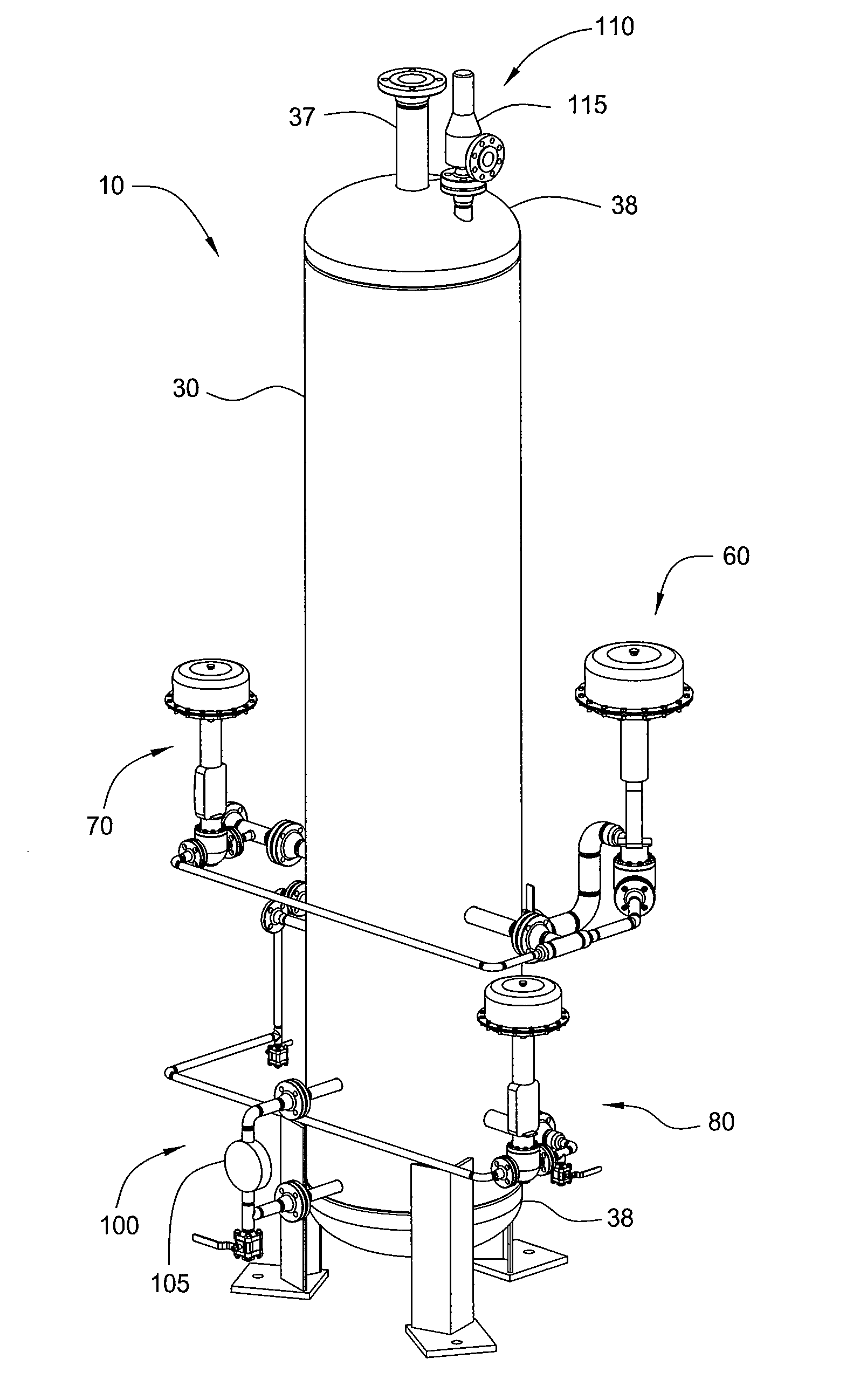

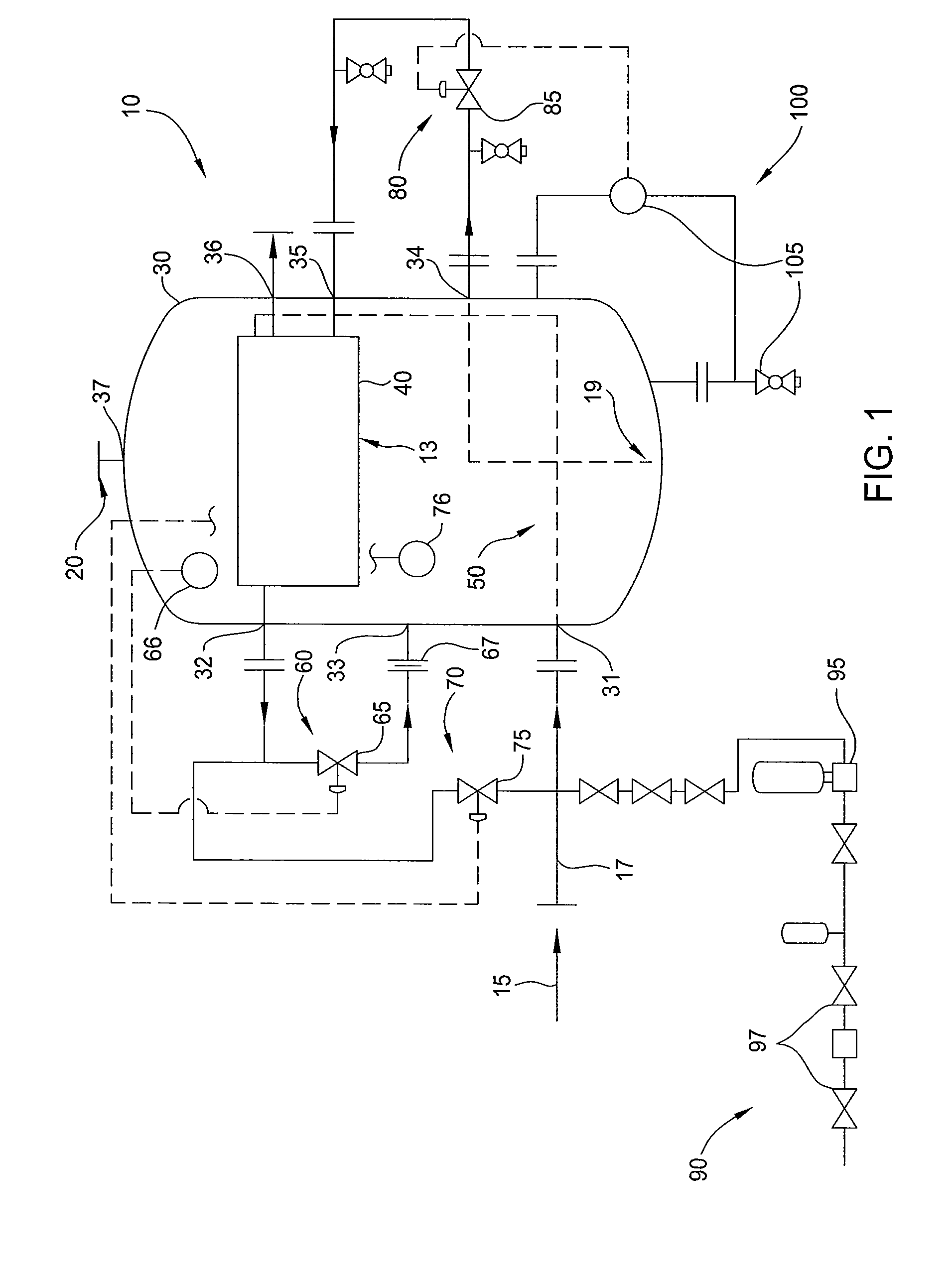

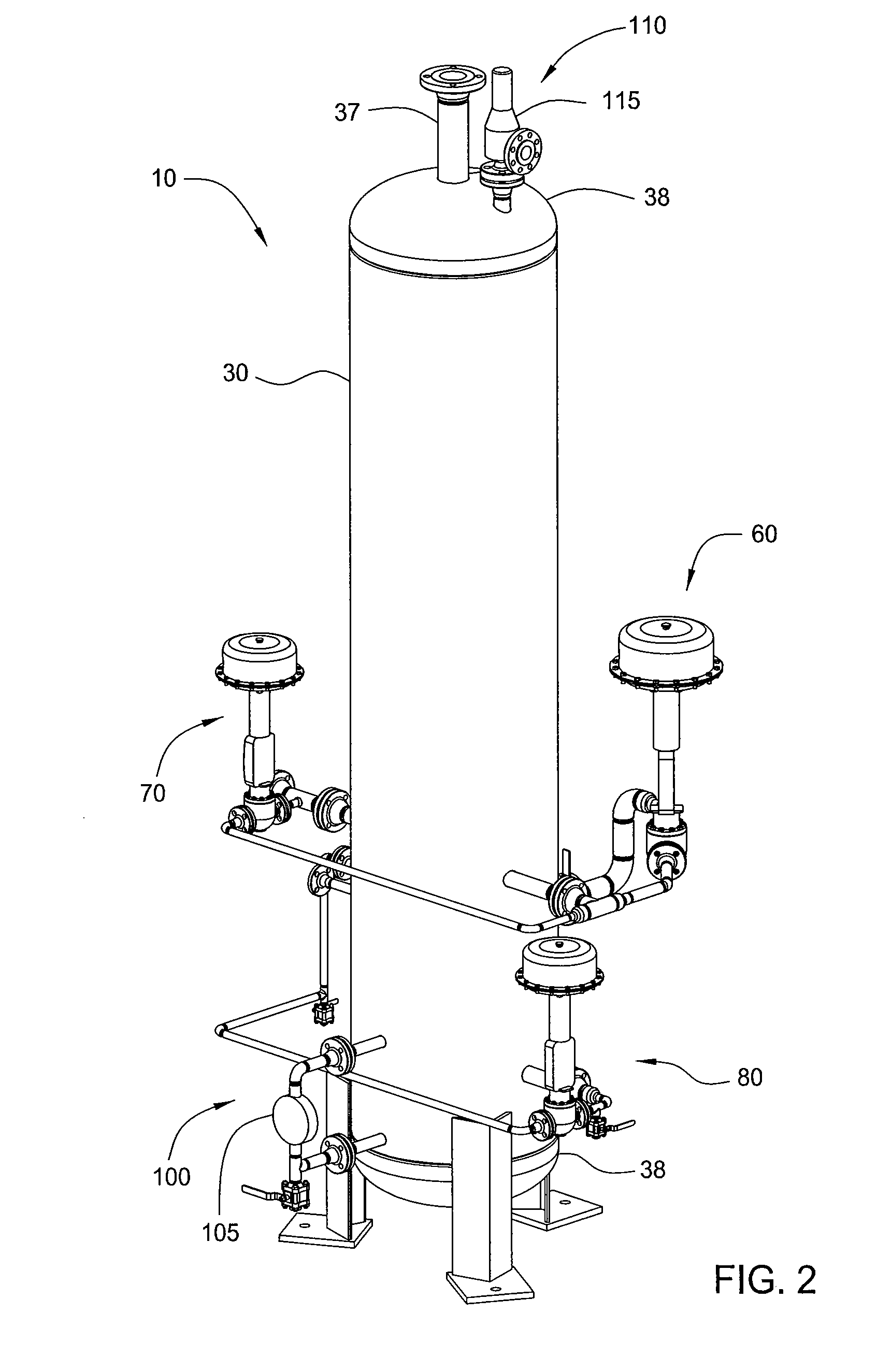

[0049]FIG. 1 illustrates a process and instrumentation diagram of a system 10. The system 10 is operable to treat a variety of fluids, such as hydrocarbon bearing fluids. In one embodiment, the system 10 may be a fuel gas conditioning unit operable to reduce the heating value of a gas stream, by separating and removing propane and heavy hydrocarbons from the gas stream to provide a lean lower BTU fuel stream. In one embodiment, the system 10 may be a dew point control unit operable to control the hydrocarbon dew point of a gas stream by lowering the hydrocarbon dew point of the gas stream to prevent liquid formation in the gas stream or by increasing the hydrocarbon dew point of a separated portion of the gas stream to stabilize the separated portion of the gas stream, for transfer to a pipeline or other end-user consumer of gas.

[0050]In one embodiment, the system 10 is used to treat a natural gas stream 15 to produce a conditioned fuel gas stream 20. The conditioned fuel gas stream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com