Method and Apparatus to Effect Heat Transfer

a heat exchanger and heat exchange technology, applied in lighting and heating apparatus, heat recovery, greenhouse gas reduction, etc., can solve the problems of large quantities of byproduct heat or waste heat, inefficiency that is commonly accepted as the norm, and difficult to find useful applications, so as to reduce the discharge of pollutants, reduce the effect of heat dissipation to atmosphere, and effective heat capture and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

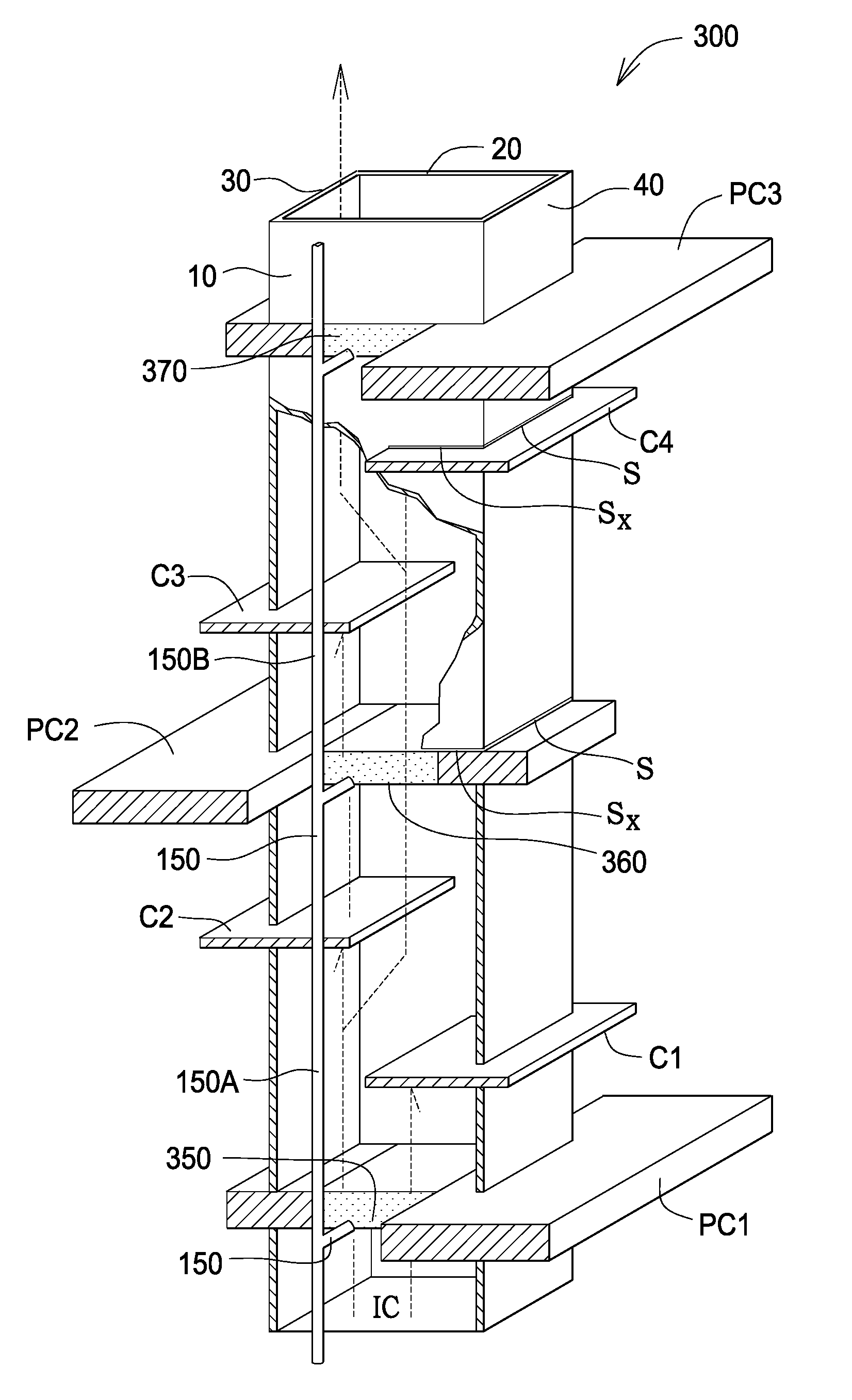

embodiment 100

[0062]Embodiment 100 receives combustion gases from a combustion unit (not shown). The A series of fins originate from an inner portion of device 100 and extend outwardly through each of walls 10, 20, 30 or walls 10, 20, 40. Combustion core inlet IA is offset from fin A1. Flow from core inlet IA is directed in a substantially serpentine path as bounded by the A series of fins and as shown conceptually by the dotted lines and arrows. Not only do the fins collect and conduct thermal energy, they serve to restrict the flow of combustion gases through a unit and can be used to promote turbulence. In all forms, the fin devices close to the source of heat receive heat from the products of combustion delivered from the combustion unit and / or burner, and conduct heat to the designated medium. In an alternate configuration, core inlet IA could be placed directly under fin A1 if required by the particular application.

[0063]To increase the likelihood that combustible substances are joined with...

embodiment 200

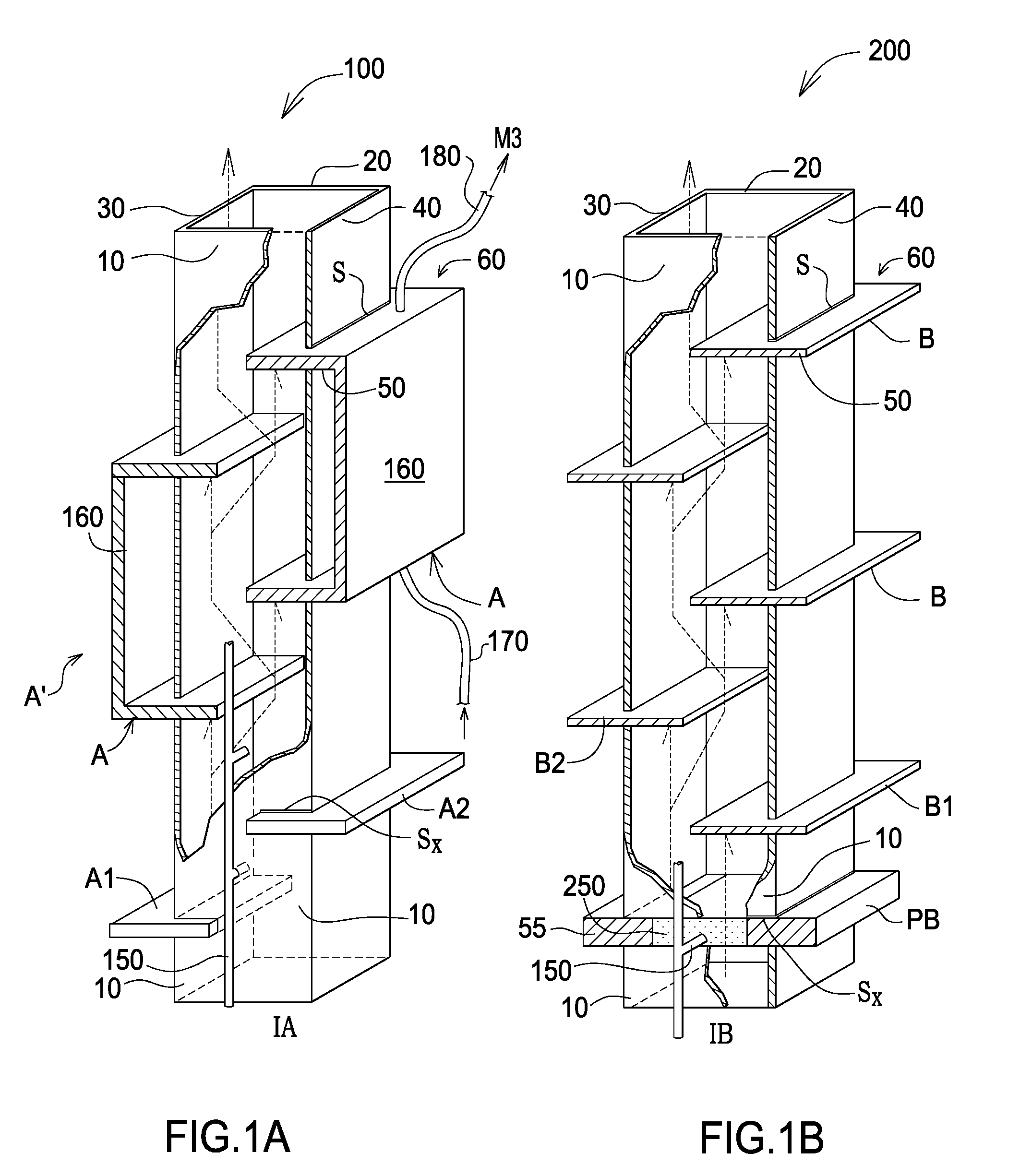

[0075]As stated above, the profile of the disclosed fins can be lengthened in directions z and / or (−) z. That of the finned plates can be lengthened in one or more directions x, y, z or directions (−) (x, y, z). In embodiment 200, plate PB extends outwardly in a right to left configuration from side walls 30, 40. Outer front surface 55 of finned plate PB is shown to be substantially flush with the inner surface of the front wall 10. Correspondingly, the outer back surface of the finned plate would be substantially flush with the inner surface of the back wall 20.

[0076]The B series of fins originate from an inner portion of device 200 and extend outwardly through each of walls 10, 20, 30 or walls 10, 20, 40. The fins are mounted in receiving slots S in the side walls of unit 200. The B series of fins jut from side walls 30, 40 in a substantially perpendicular fashion relative to the outer surface of side walls 30, 40. The outer front surfaces 50, 60 of the B series of fins extend out...

embodiment 300

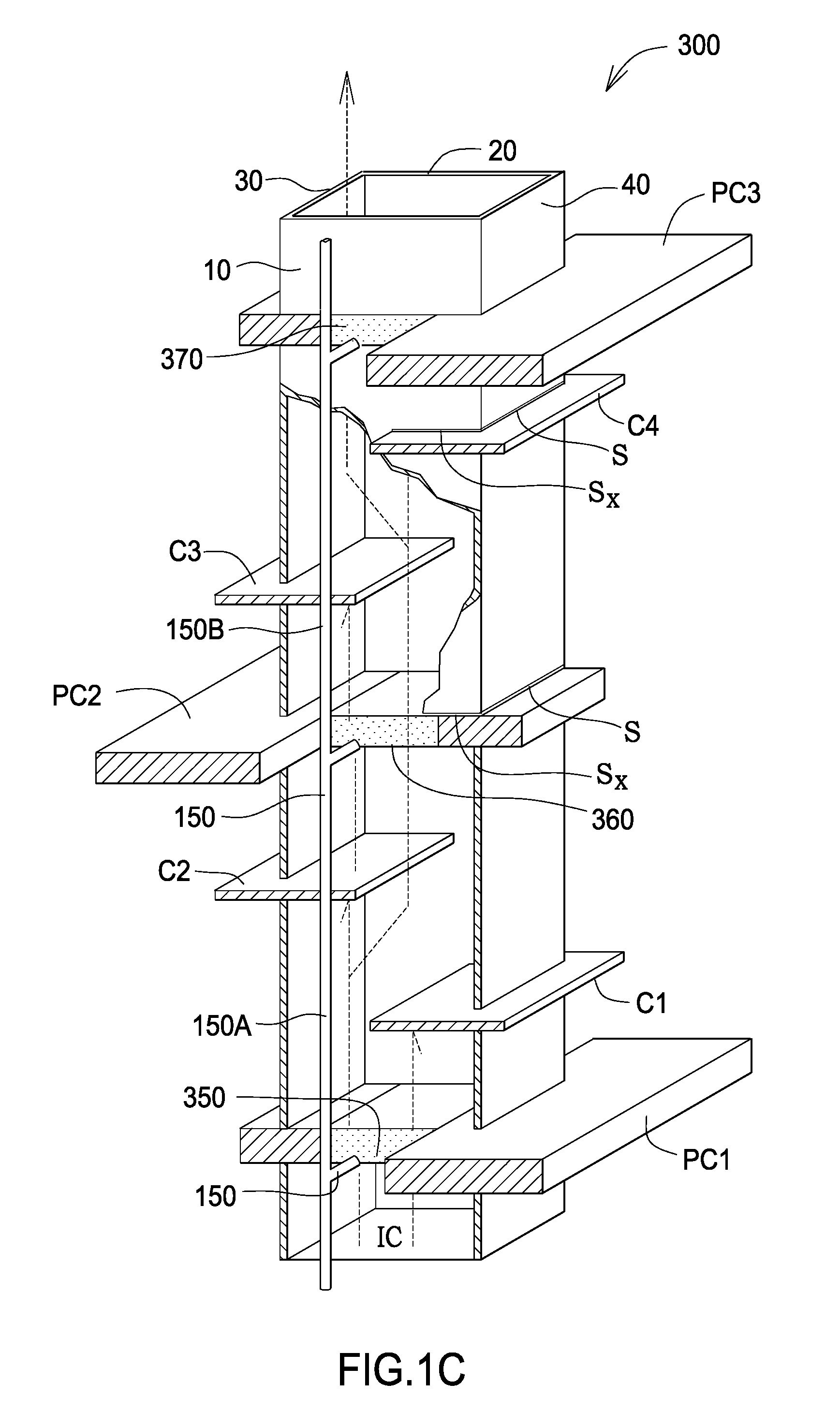

[0089]In FIG. 1C is shown an embodiment 300 comprising walls 10, 20, 30, 40 and a series of thermally conductive fins C1, C2, C3, C4 mounted horizontally in walls 30, 40. Finned plates PC1, PC2 and PC3 extend beyond walls 30, 40. A finned plate PC1 extends across the primary combustion core, the inlet of which is centrally aligned. A discrete stage is formed between finned plates PC1 and PC2 and between PC2 and PC3. As shown, there could be two discrete stages having three sub-stages. Each of the two discrete systems potentially provide for a discrete combustion area. With the appropriate catalytic device(s) and / or excess air, sequential combustion can be achieved. In other words, inlet gas through core ICcould undergo a combustion process at finned plate PC1. Heat capture can occur at finned plates PC2, PC3 whereby heat can be transferred to its terminus. Inlet gas could also undergo a combustion process at finned plate PC2 or in the systems bounded by finned plates PC1 and PC2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com