Bioreactor and method for producing microbial cellulose

a technology of microbial cellulose and bioreactor, which is applied in the direction of bioreactor/fermenter, specific use of bioreactor, biochemical apparatus and processes, etc., can solve the problems of insufficient cylinders to produce tubular microbial cellulose, laborious and time-consuming,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Three Hollow Tubes Fitted Together as a Group

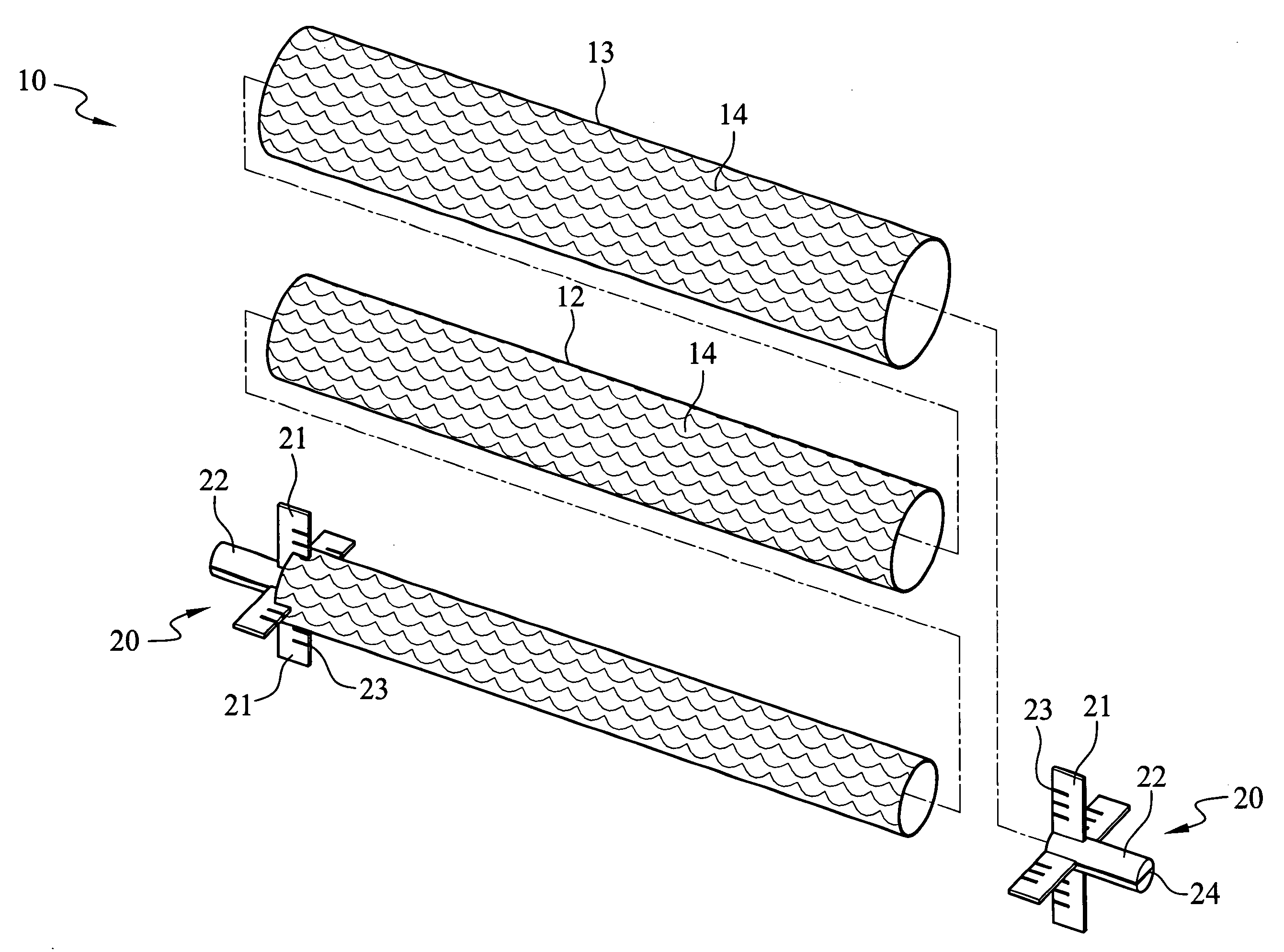

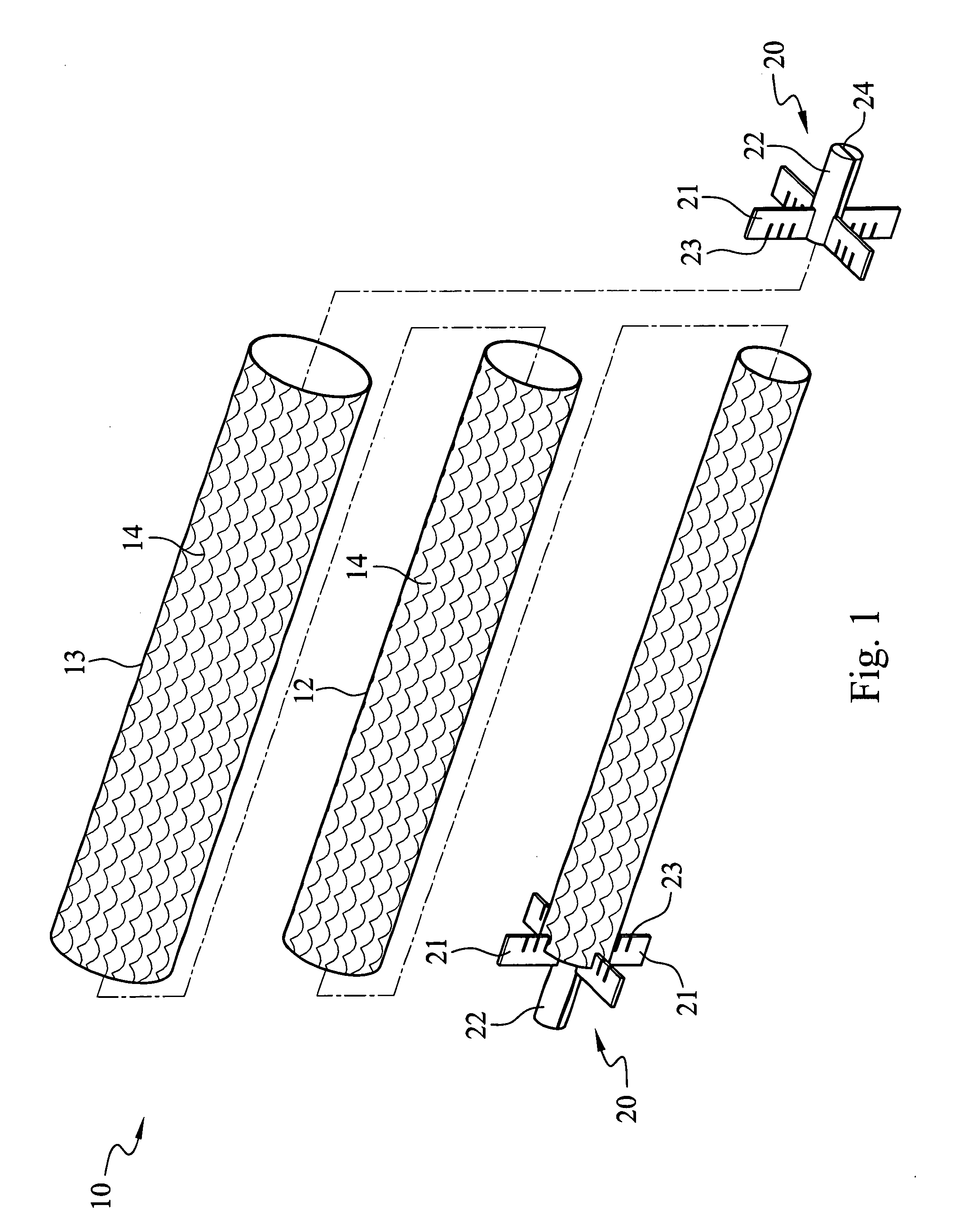

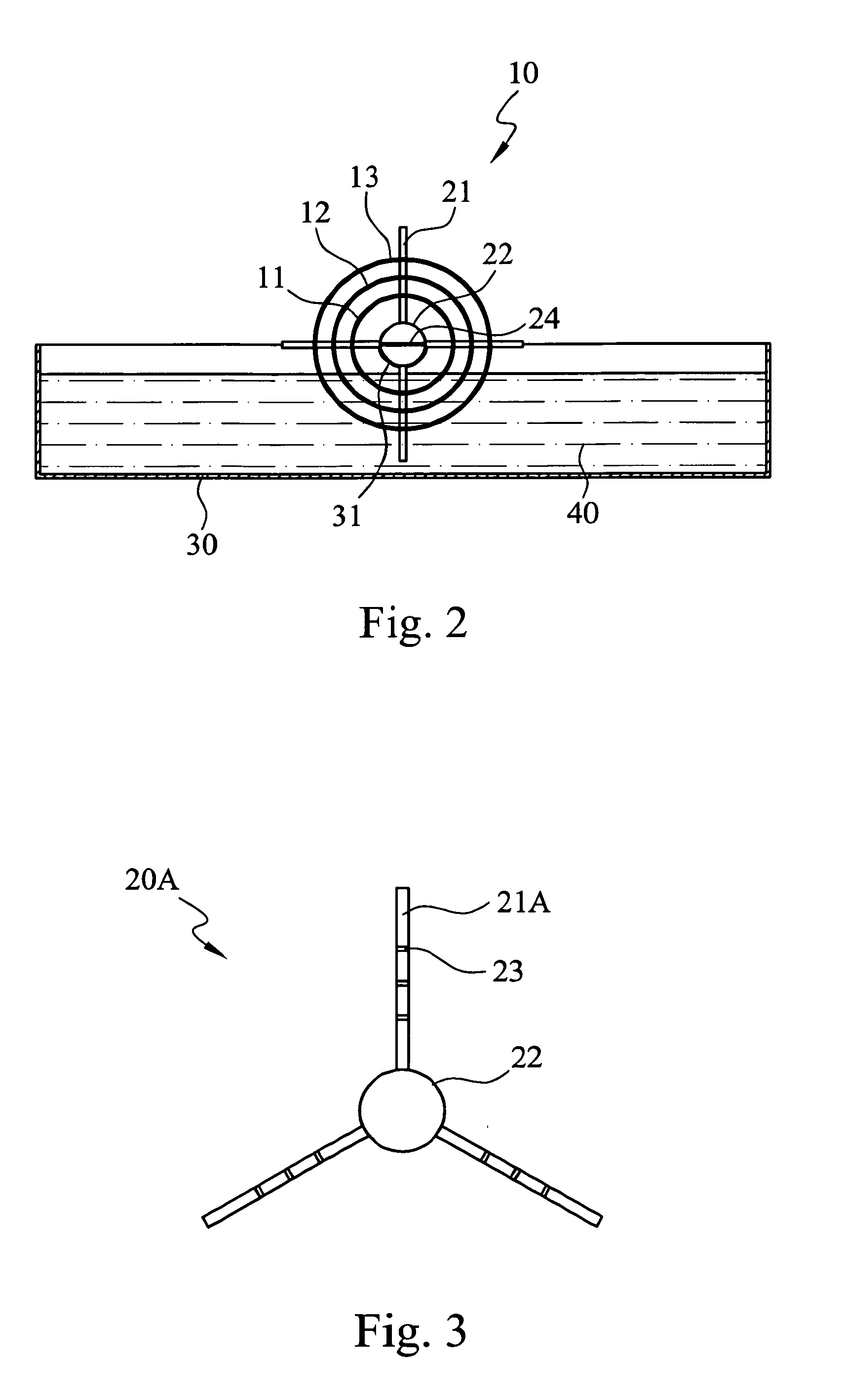

[0038]In this example, the bioreactor shown in FIGS. 1 and 2 was used, wherein the container 30 has a length of 33 cm, a width of 23 cm, and a height of 4 cm, and the three hollow tubes 11-13 have a length of 30 cm. The shafts 22 were driven into rotation by a motor at 10 rpm. Consequently, the horizontal module 10 was rotated horizontally at 10 rpm as well.

[0039]The bioreactor was placed in an environment free of contaminating bacteria in order to carry out microbial cultivation, in which the liquid medium 40 held in the container 30 was 35 mm of height, and the culture temperature was 30° C. The liquid medium 40 was a pre-agitated culture prepared in advance. The pre-agitated culture was a liquid medium comprising the ingredients listed in the following table and 5% microorganisms, the culture was incubated free of contaminating bacteria at 120 rpm and 30° C. for two days, and was filled with Gluconacetobacter xylinus by the time the in...

example 2

Two Hollow Tubes Fitted Together as a Group

[0042]The steps and the bioreactor employed in Example 1 were also used in this embodiment, except that the second hollow tube (with a diameter of 40 mm) from the three hollow tubes was not used.

[0043]Overall, 1.745 g / L of sheets of bacterial cellulose was obtained from the undisturbed portion of liquid medium, and two different sizes of tubular bacterial cellulose, which weighed 1.815 g / L in total; were obtained from the horizontal module, and resulted in a total harvest of 3.56 g / L in this example.

example 3

A Single Hollow Tube

[0044]The steps and the bioreactor employed in Example 1 were again used in this embodiment, except that the first and the second hollow tubes (with a diameter of 30 mm and 40 mm, respectively) from the three hollow tubes were not used.

[0045]In this example, 1.745 g / L of sheets of bacterial cellulose was obtained from the undisturbed portion of liquid medium, and one tubular bacterial cellulose, which weighed 0.77 g / L in total; was obtained from the horizontal module, and resulted in a total harvest of 2.515 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com