Environmental Protection and Energy Saving Heater

a heater and environmental protection technology, applied in the field of environmental protection and energy saving heaters, can solve the problems of high cost, easy waste of power resources, and pollution of the surrounding environment, and achieve the effects of saving energy, reducing energy consumption, and improving heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]In order to make better understanding of this invention for this technical field staffs, attached map and implementation method for further details.

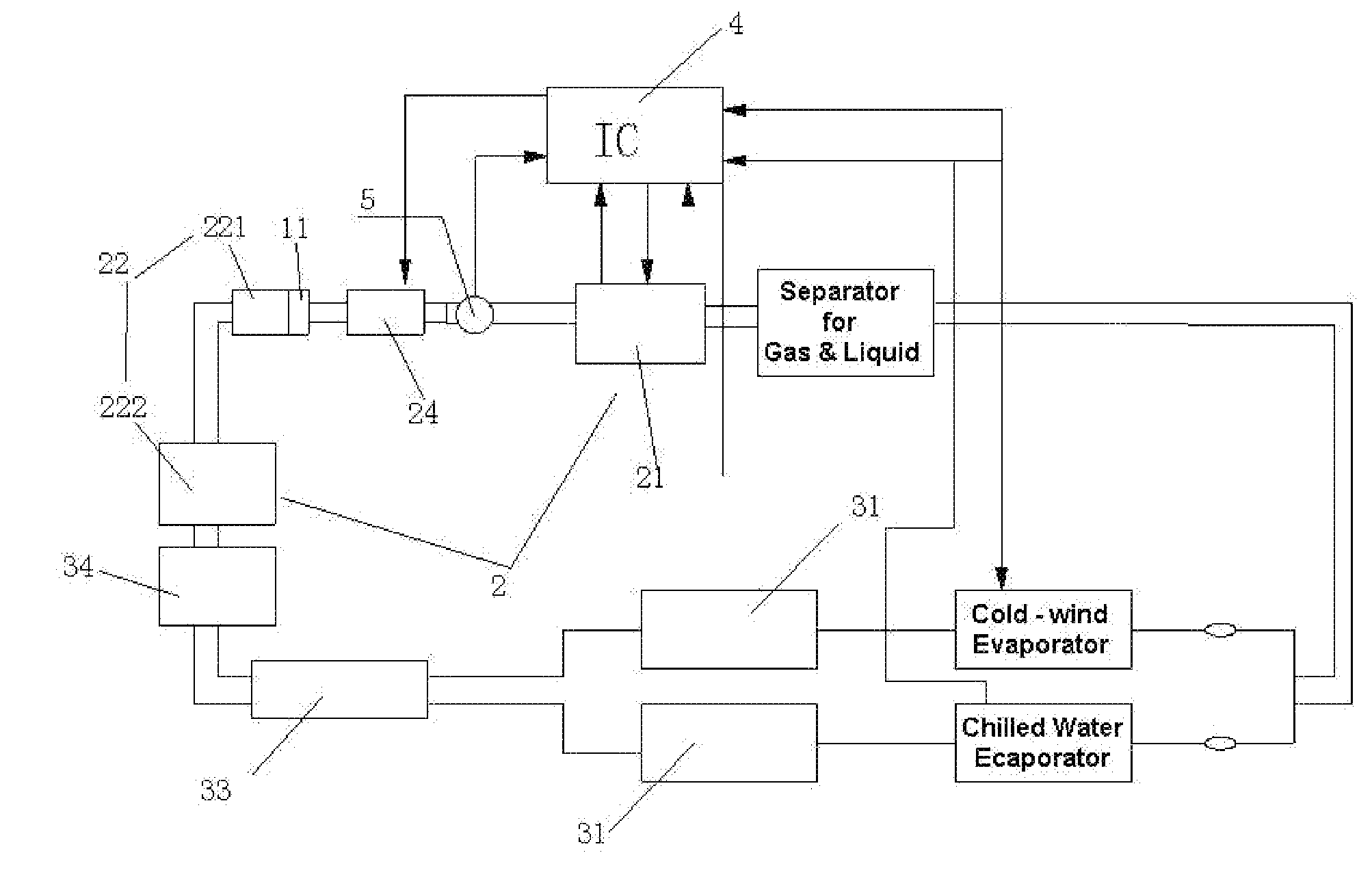

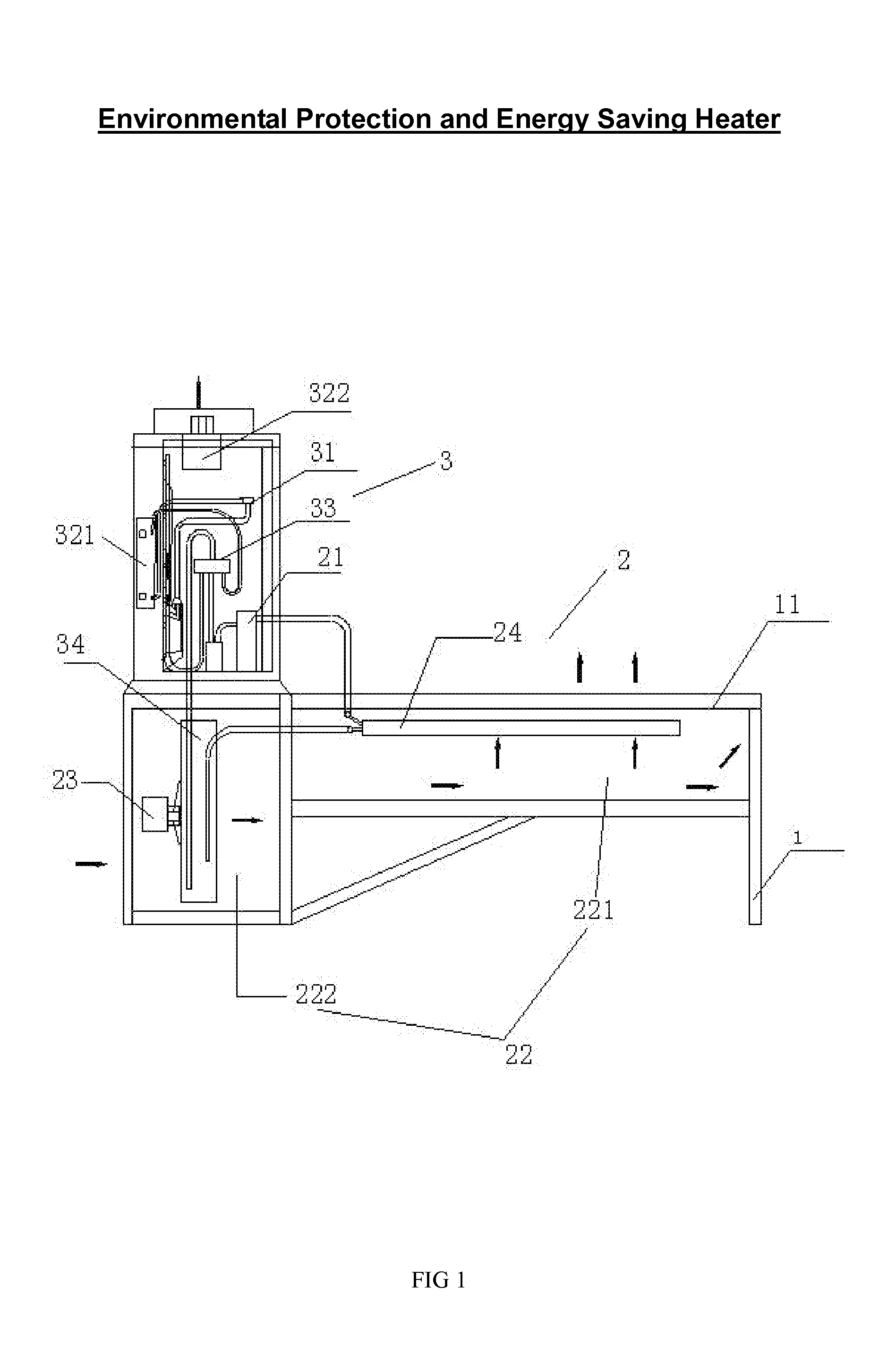

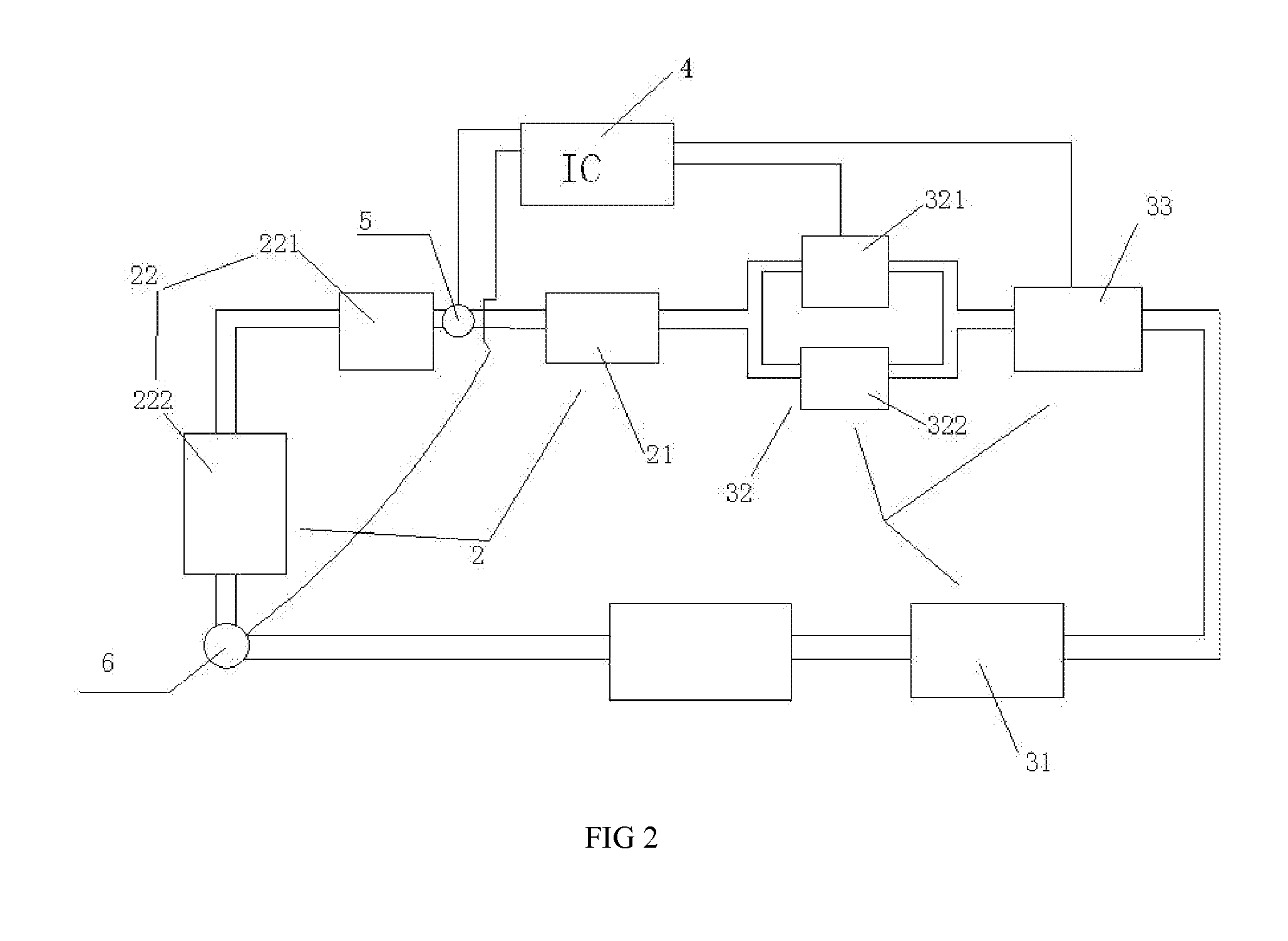

[0021]Refer to FIG. 1 to FIG. 4, which shows a new type of environmental protection and energy saving heater, including heater bracket 1, hot roast cell 2, refrigeration cell 3 which connect with hot roast cell. The hot roast cell and refrigeration located in bracket. Therein to, the hot roast cell 2 including compressor 21 and condenser 22 which connected with compressor 21, condenser 22 is an interconnected two condensers 221, 222, there is a blower 23 at a side of second condenser 222.

[0022]There is a heat collector and emission panel 11 set up on first condenser 221 for roast using. The second condenser 222 is used for heating the Heater and reusing the waste heat, and then blowing strong wind into the first condenser 221, to reuse the waste heat in second condenser 222, and transfer the low-quality heat into high-quality heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com