Exhaust gas purifying apparatus

a technology of exhaust gas purification and purification apparatus, which is applied in mechanical apparatus, exhaust treatment electric control, machines/engines, etc., can solve the problems of deteriorating efficiency of nox reduction in comparison to urea water usage, difficulty in providing distance of apparatus, and increase in quantity of unreacted urea water supplied to scr catalytic module without hydrolysis into ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

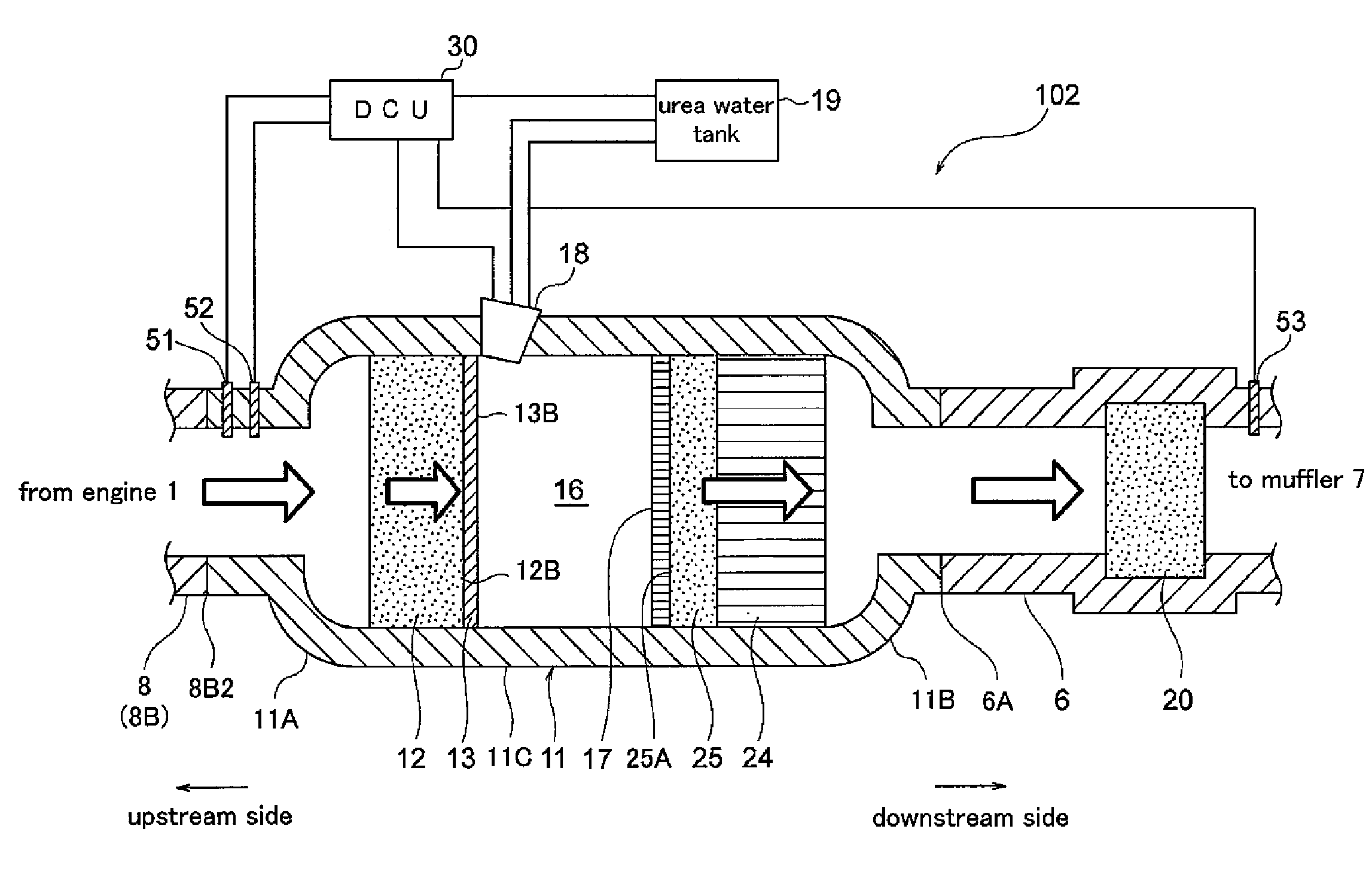

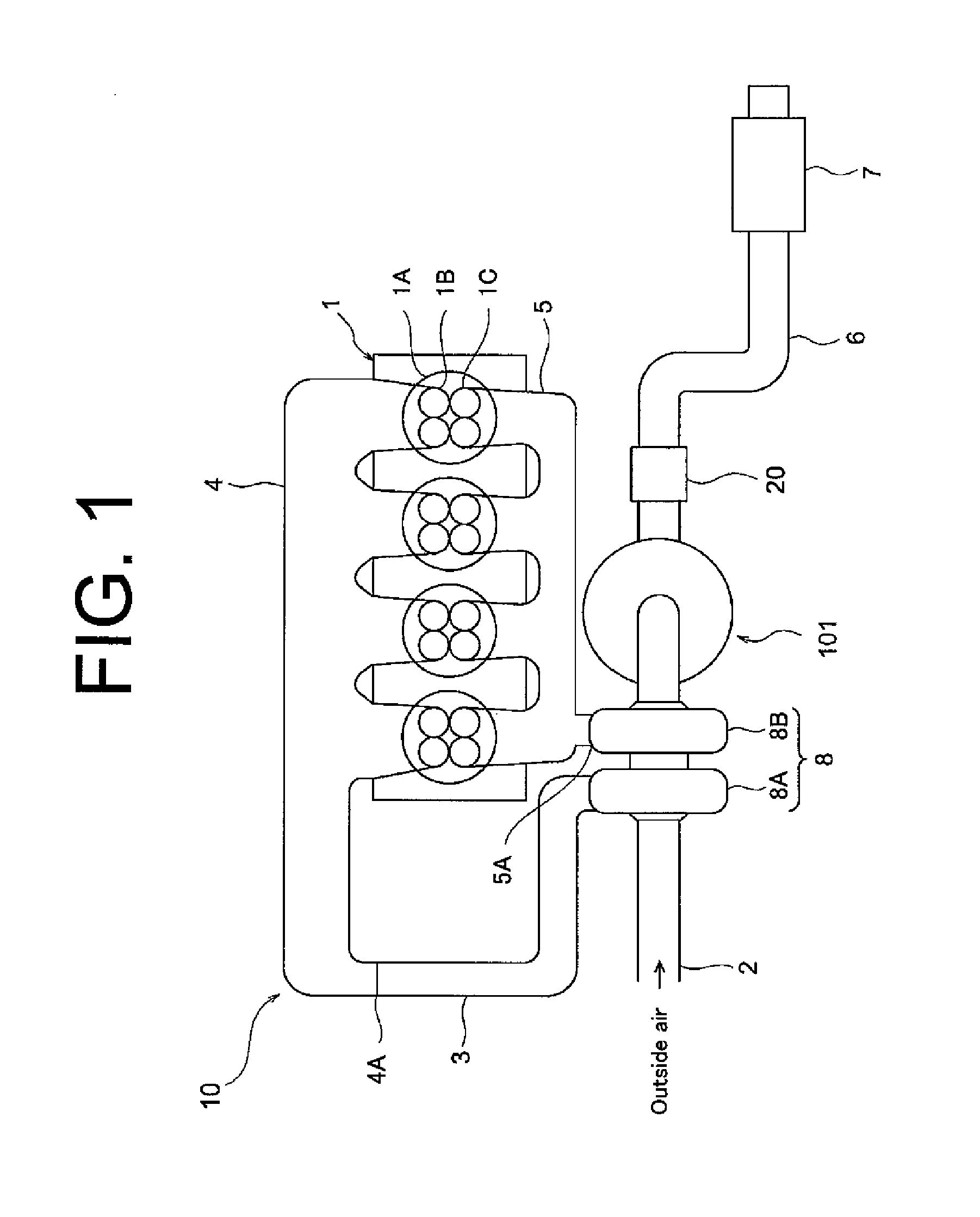

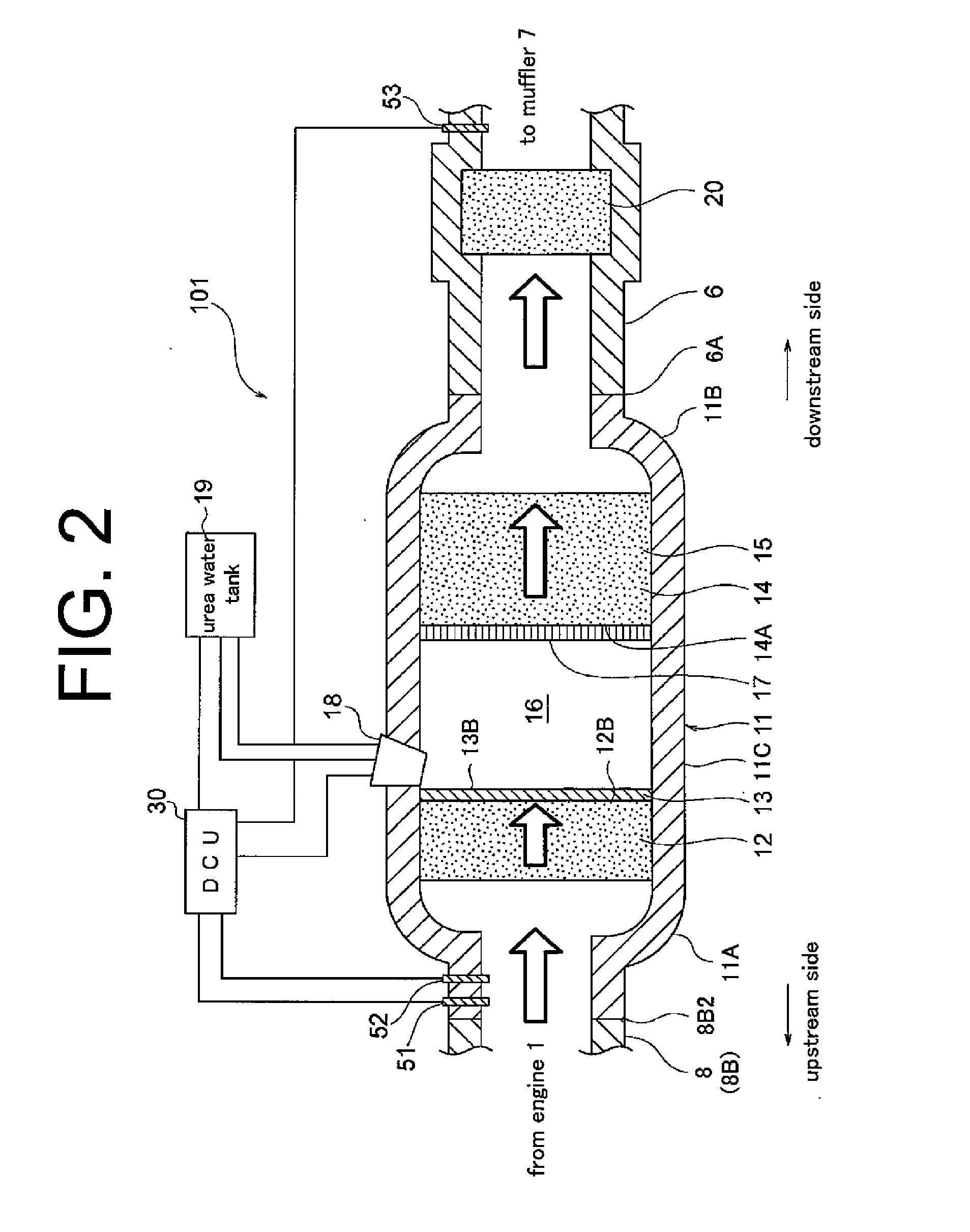

The following will describe the embodiments of the exhaust gas purification apparatus according to the present invention with reference to FIGS. 1 through 3. Referring to FIGS. 1 and 2 showing the first embodiment, the exhaust gas purification apparatus which is designated generally by 101 and its associated components will be described. The exhaust gas purification apparatus 101 is employed in a vehicle equipped with a diesel engine.

Referring to FIG. 1, an engine assembly including an engine 1 and the exhaust gas purification apparatus 101 is designated generally by reference numeral 10. The engine 1 has a plurality of cylinders 1A each having an intake port 1B to which an intake manifold 4 is connected for distributing intake air to the respective cylinders 1A. The intake manifold 4 has an inlet 4A to which an engine intake pipe 3 is connected and the engine intake pipe 3 is further connected to a compressor housing 8A of a turbocharger 8. The compressor housing 8A is connected to...

second embodiment

In the second embodiment, the oxidation catalyst layer 12, the SCR catalyst layer 25, the DPF 24 and the injection valve 18 are all provided in the casing 11 of the exhaust gas purification apparatus 102, but the present invention is not limited to this structure. For example, only the DPF 24 may be provided outside the casing 11 separately from the other components.

In the first and second embodiments, the oxidation catalyst layer 20 is provided separately from the exhaust gas purification apparatuses 101, 102, but the present invention is not limited to this structure. The oxidation catalyst layer 20 may be provided inside the casing 11 downstream of the DPF 14, 24 of the exhaust gas purification apparatuses 101, 102, respectively.

The injection valve 18 is provided downstream of the oxidation catalyst layer 12 so as to supply urea water to the hydrophilic layer 13 in the exhaust gas purification apparatuses 101, 102 according to the first and the second embodiments, respectively, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com