Linear X-ray detector using fiber optic face plate to alter optical path

a fiber optic face plate and detector technology, applied in the direction of material analysis using wave/particle radiation, instruments, radiation control devices, etc., can solve the problem that x-rays cannot be focused, and achieve the effect of high resolution, low cost and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

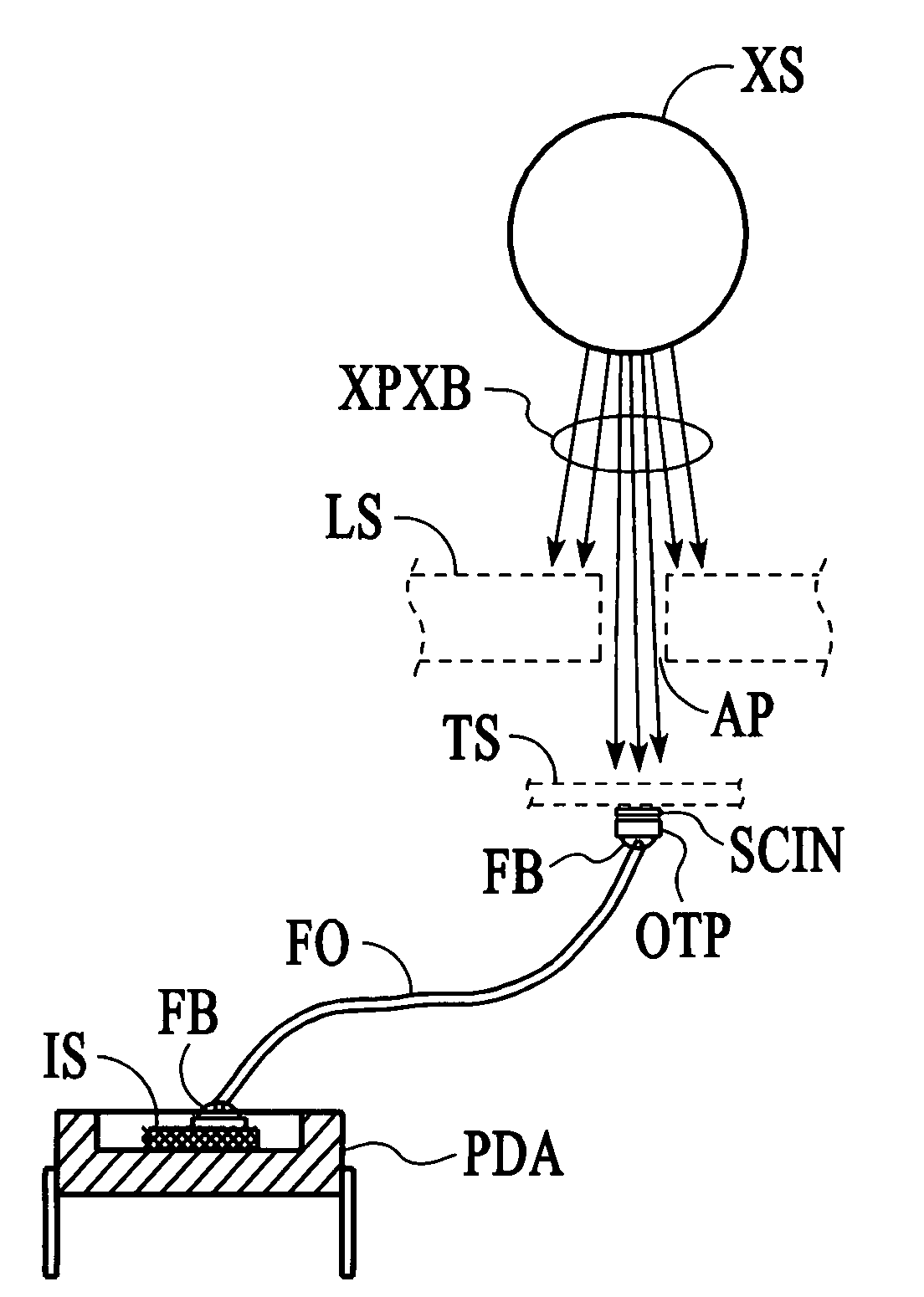

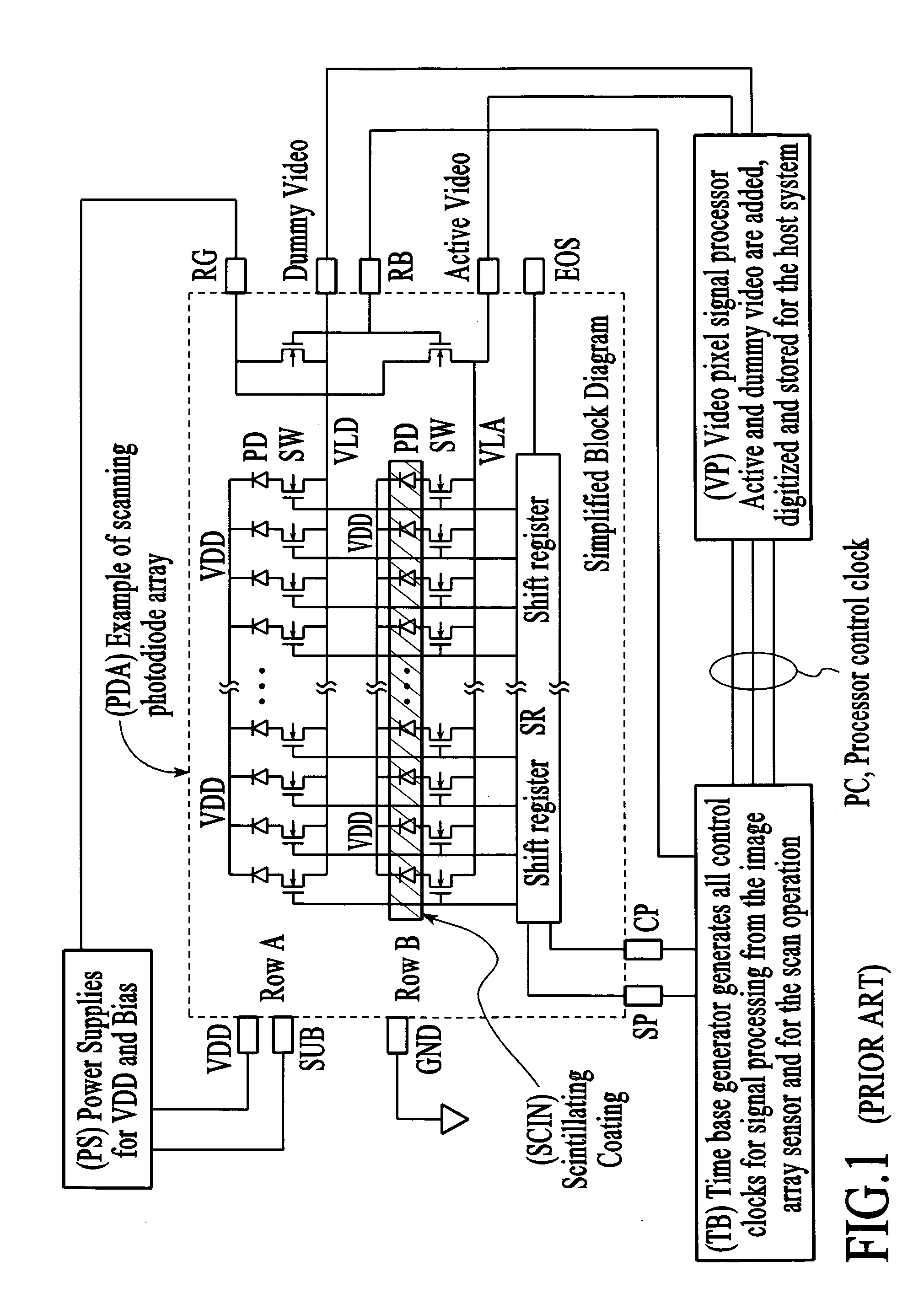

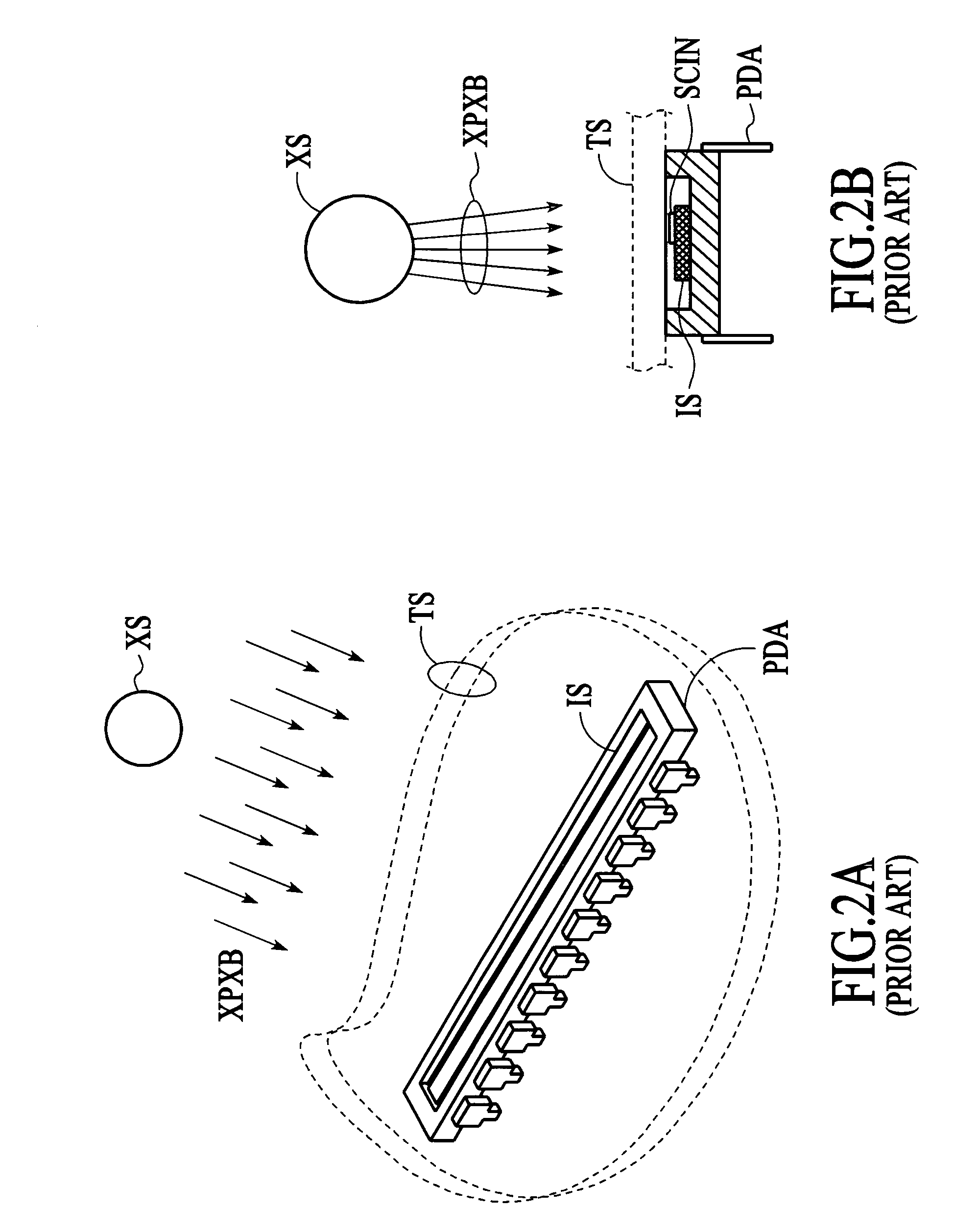

[0055]The present invention is a linear X-ray detector system 1. The detector system 1 is based on a unique image transferring characteristics of a fiber optic face plate 13, as illustrated in FIG. 6. The fiber optic face plate 13 is installed in the system 1 as illustrated in FIG. 7. FIG. 7 is a cross-sectional view of the X-ray detector system. The length of the detector perpendicular to the plane of the paper is determined by the length of the specimen to be scanned. The detector system 1 comprises a layer of scintillating material 14, a fiber optic face plate (FOFP) 13, and an array of image sensors 16. Some of the viable options for the scintillating material layer 14 are Gd2O2S:Tb (GOS or GADOX), CsI(Tl), and CdWO4. As described more fully below, the layer of scintillating material 14 is placed on the top surface of the FOFP 13 and is used to convert the impinging X-ray energies into visible light which can be detected efficiently by the image sensor array 16. FIG. 6 illustrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| ninety degrees angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com