Composite airfoils having leading edge protection made using high temperature additive manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Embodiments described herein generally relate to composite airfoils having leading edge protection made using high temperature additive manufacturing methods.

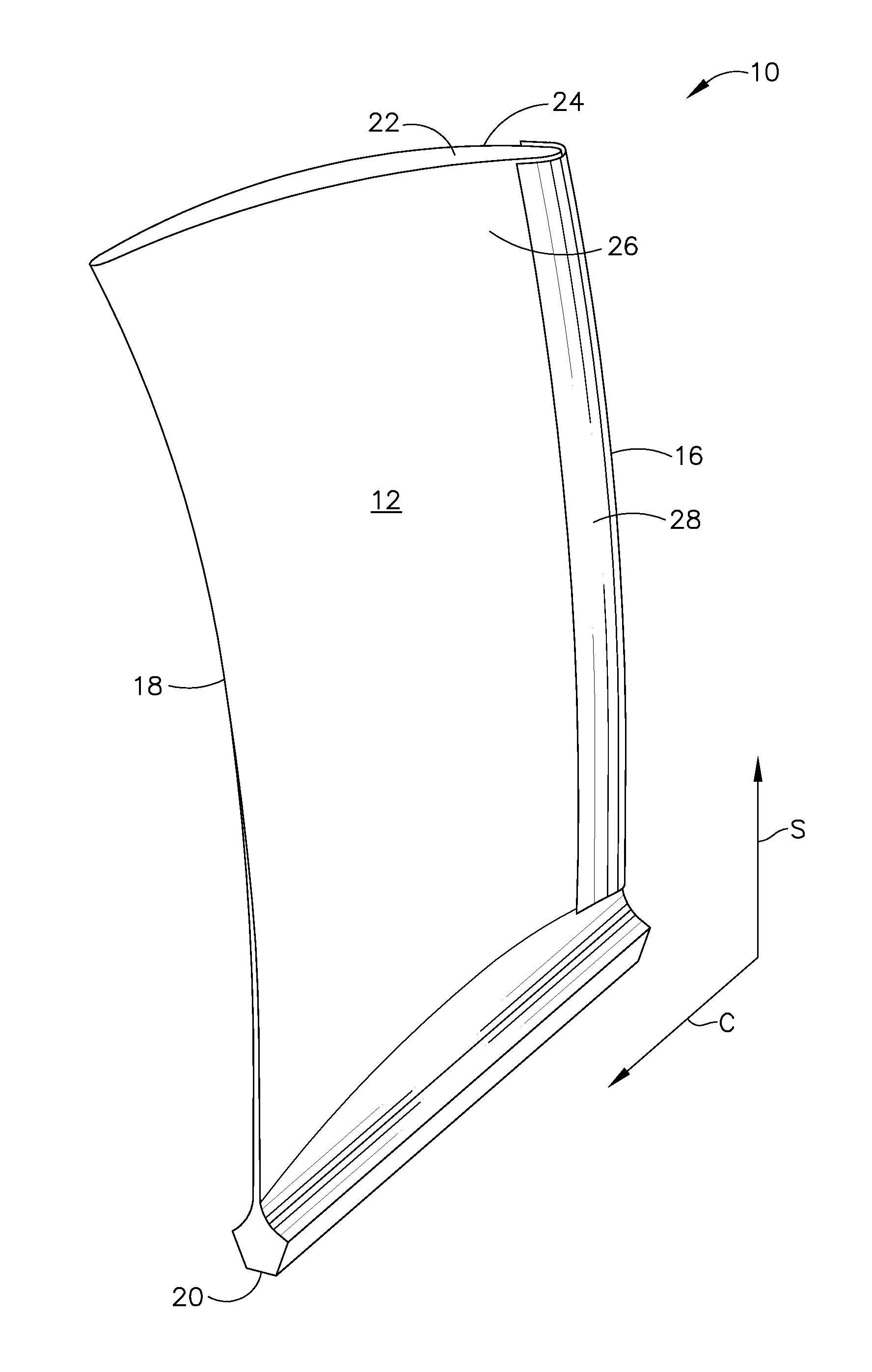

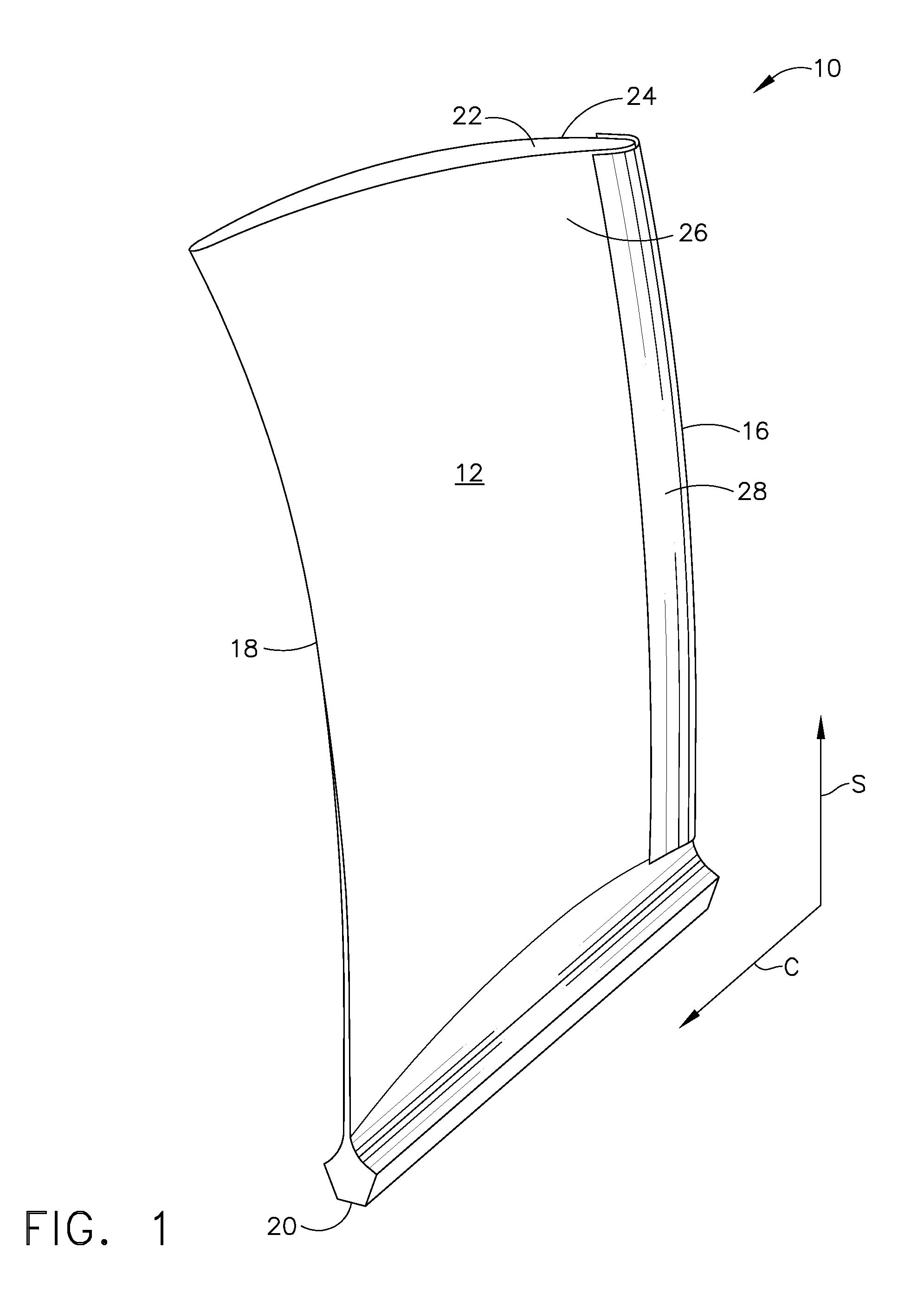

[0015]FIG. 1 is a composite fan blade 10 for a gas turbine engine having a composite airfoil 12 generally extending in a chordwise direction C from a leading edge 16 to a trailing edge 18. Airfoil 12 extends radially outward in a spanwise direction S from a root 20 to a tip 22 generally defining its span and having a suction side 24 and a pressure side 26. Airfoil 12 can be constructed from plies of composite material as is known in the art. Embodiments herein describe methods and tooling for making a titanium or titanium alloy metal leading edge (MLE) protective strip 28 for adhesion to airfoil leading edge 16. Though embodiments herein focus on composite fan blades, the methods, tooling and MLE protective strips herein are suitable for use with any composite airfoil, including blades and vanes.

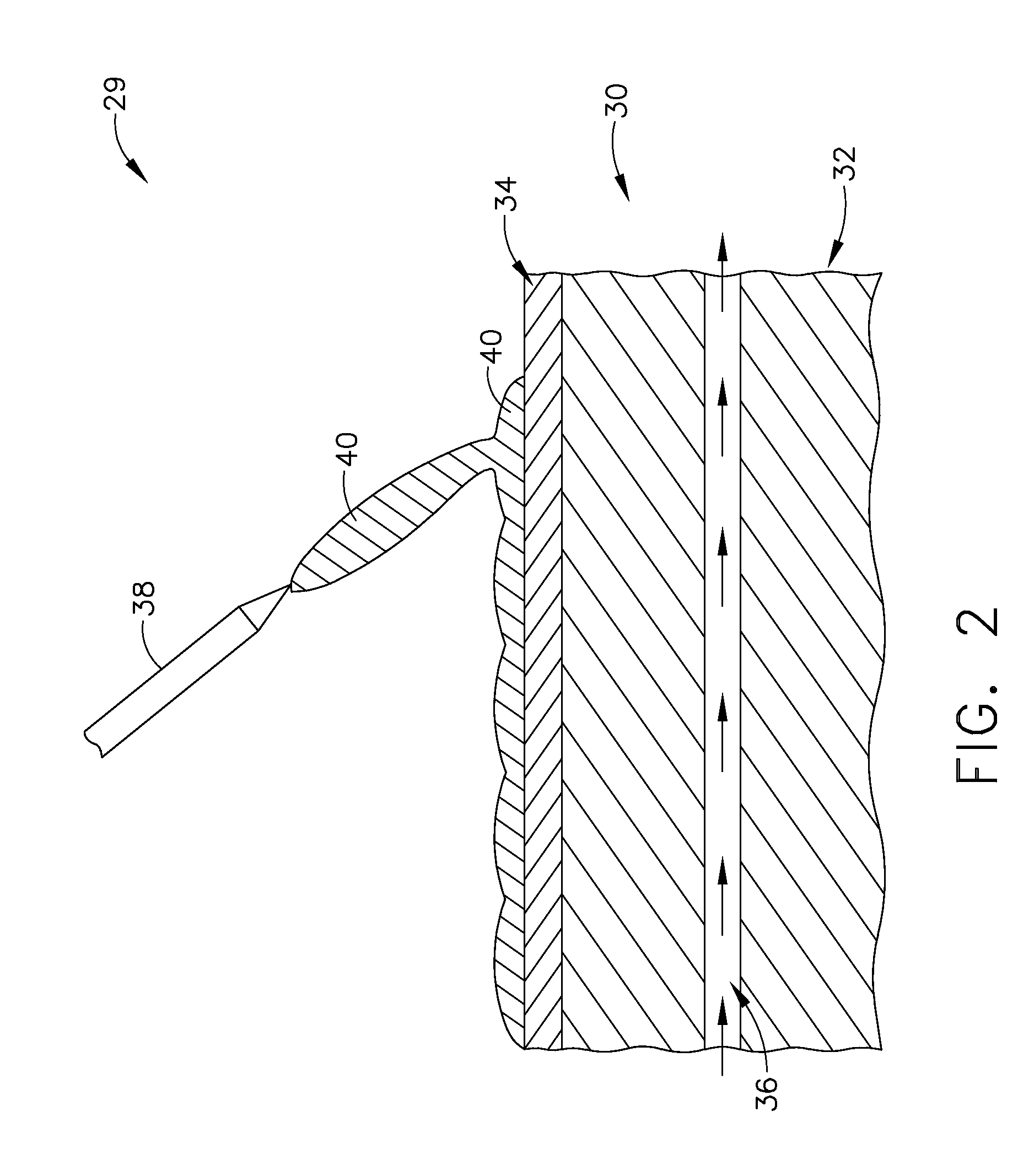

[0016]MLE protective strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com