System and method to reduce the temperature of geothermal water to increase the capacity and efficiency while decreasing the costs associated with a geothermal power plant construction

a technology of geothermal water and temperature reduction, applied in steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems of not addressing the cost savings associated with generating additional electrical power, and achieve the elimination of the need to install additional piping from many geothermal wells, maximizing energy extraction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

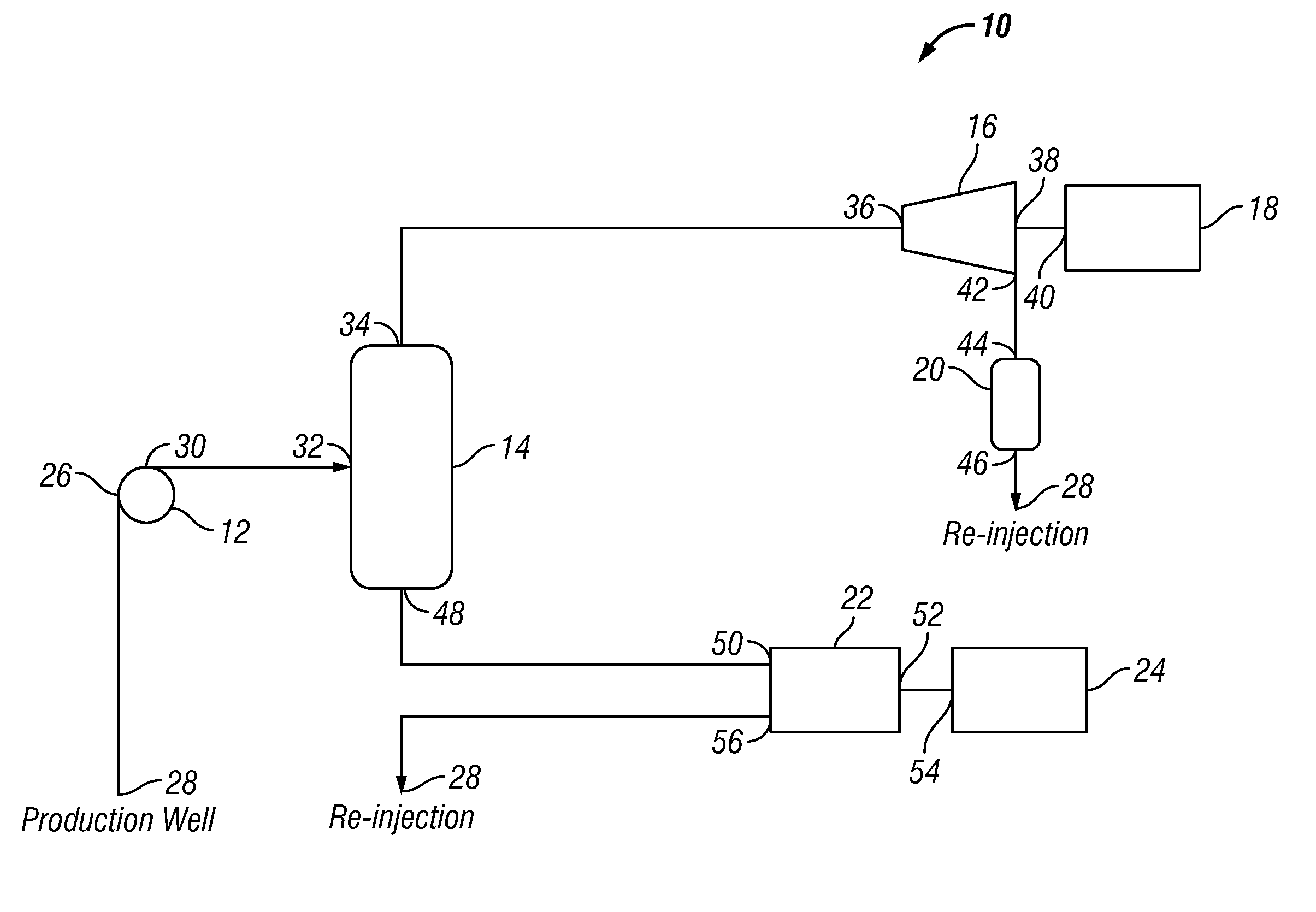

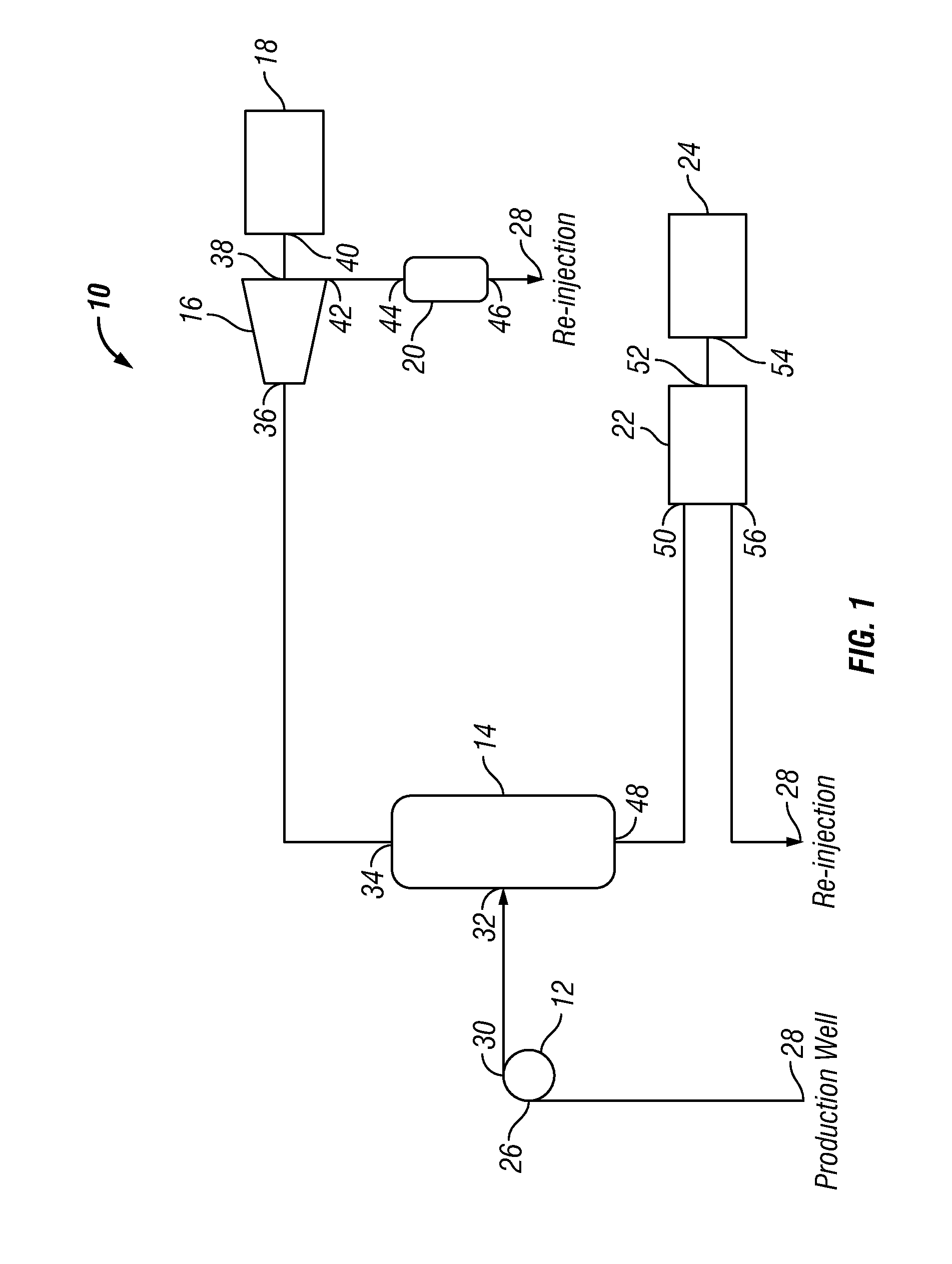

Image

Examples

example

[0038]Utilizing a 350° F. geothermal resource at a 1,750 gallon per minute flow rate the system can generate 1000 kWe net power from a resource that using current technology would only generate 1,000 kwe.

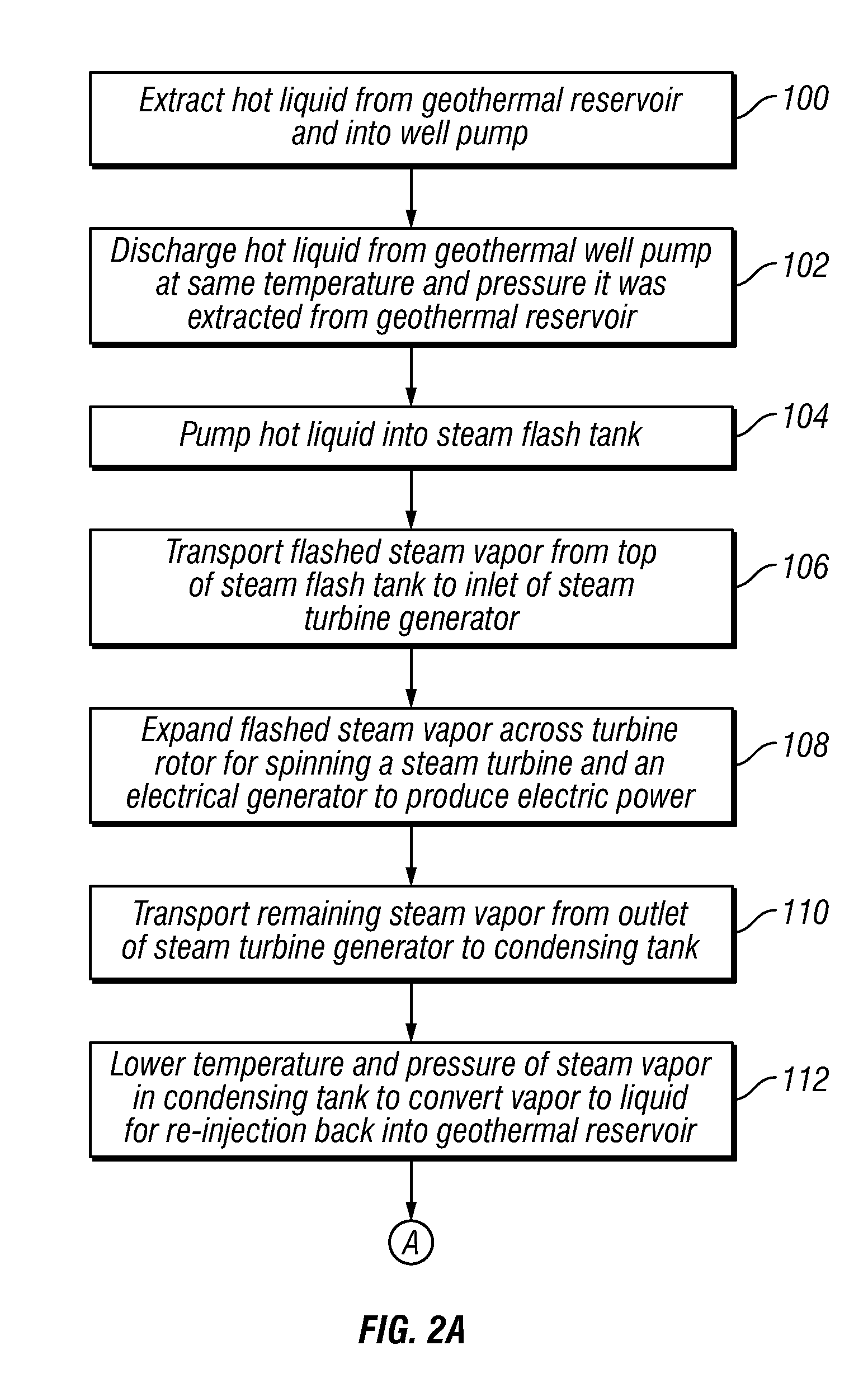

[0039]Saturated steam at a temperature of 350° F. will operate at 120 psig with a mass flow rate of 908,877 lb. per hour or converted to a liquid flow rate of 1,750 gallons per minute (gpm). By using a steam flash tank upstream of the geothermal power generation equipment the saturated steam liquid pressure can be reduced to produce a lower temperature geothermal liquid based on engineering steam tables. By reducing the 120 psig geothermal liquid to a pressure of 50 psig, 7% of the mass in the tank will flash into steam at 298° F. which can be used to operate the steam turbine. Under these conditions the steam mass flow will be 74,246 lbs per hour and the turbine generator's electrical out based on this will be 1,000 kWe. The remaining 93% of the initial mass will remain in a liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com