Gear pumps and methods for using gear pumps

a gear pump and gear technology, applied in the field of gear pumps, can solve the problems of difficult cleaning of the pump, increased disadvantages, and easy wear of the bearings, and achieve the effects of improving the sanitary conditions of the pump, and reducing the risk of damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

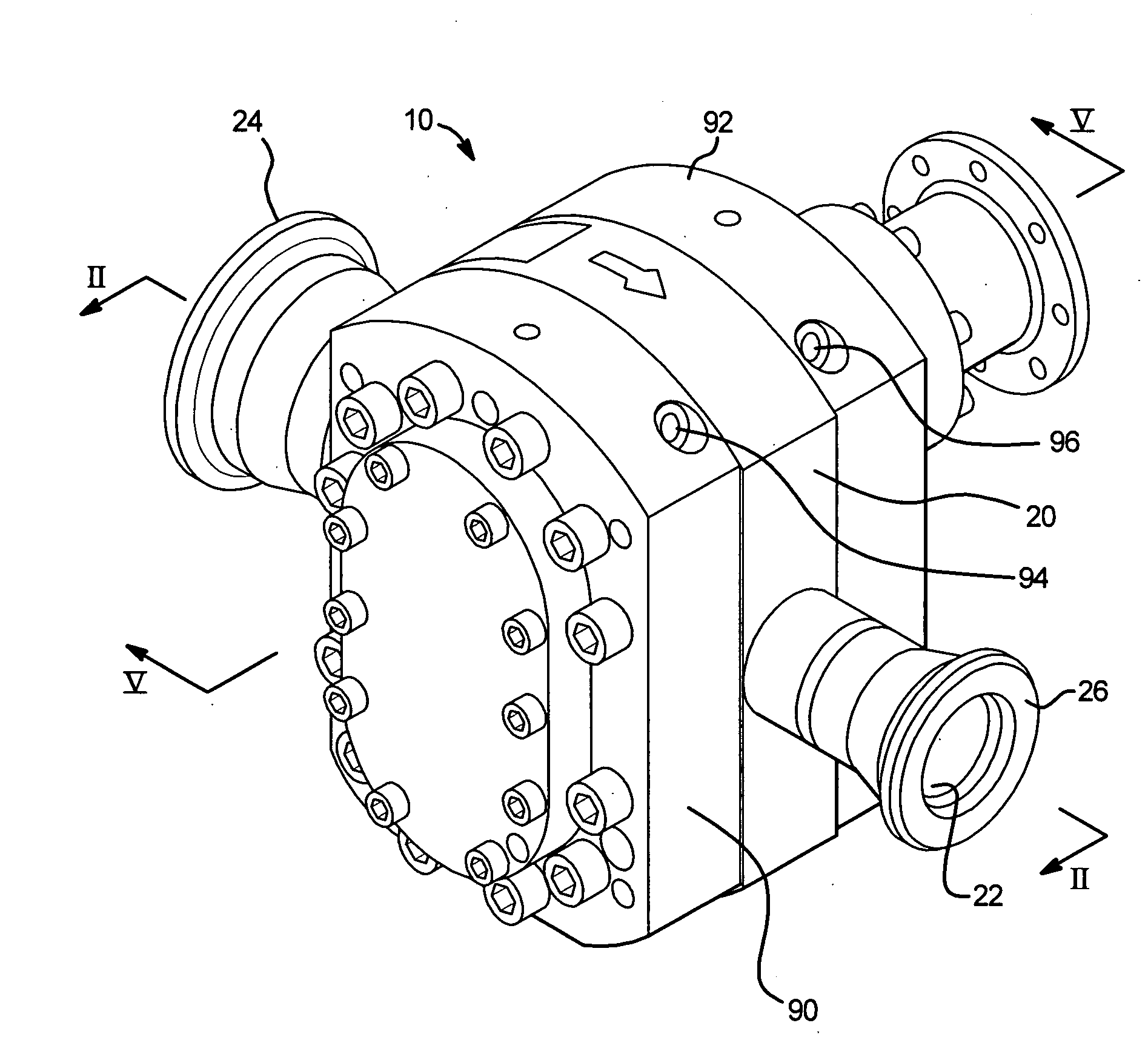

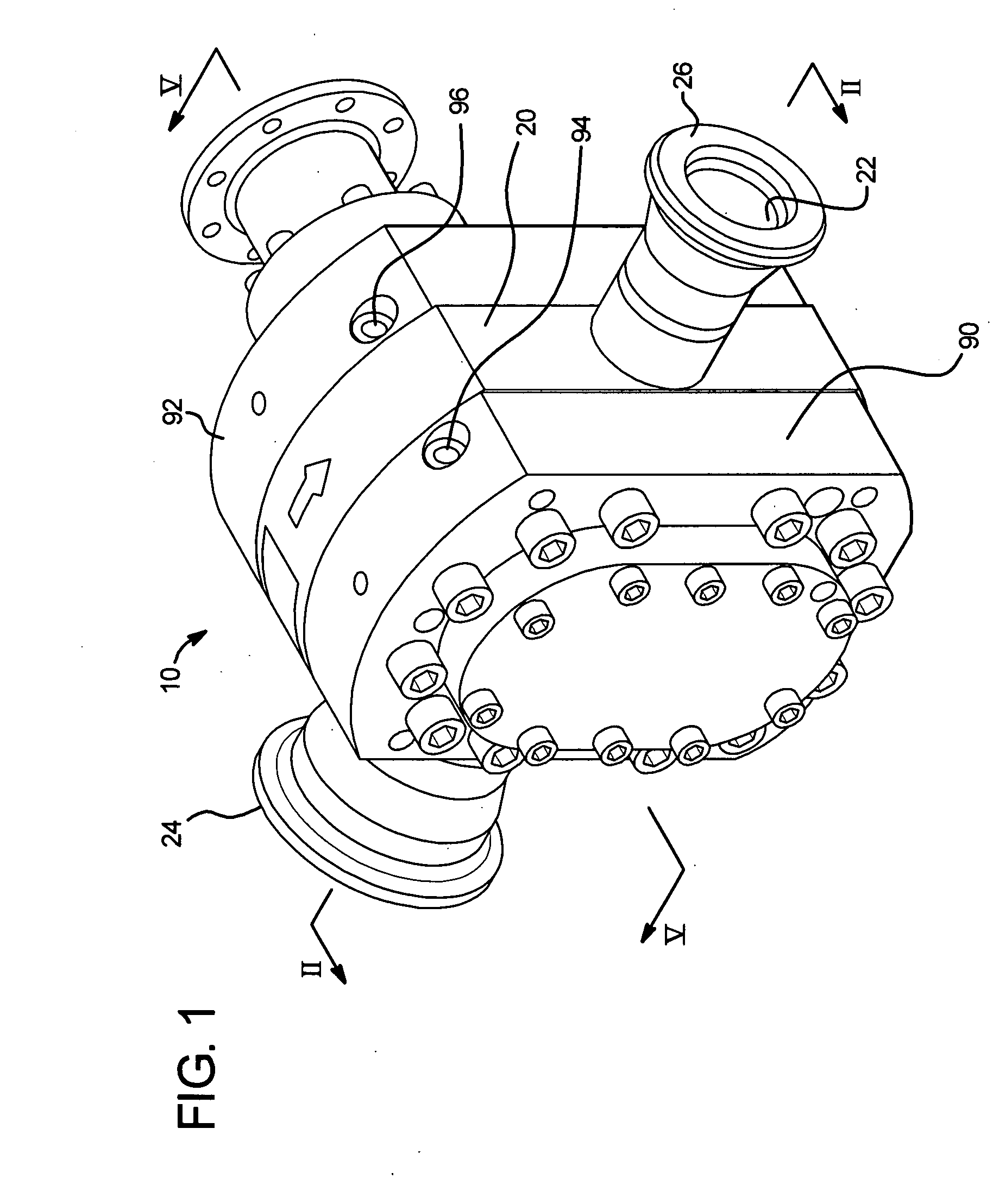

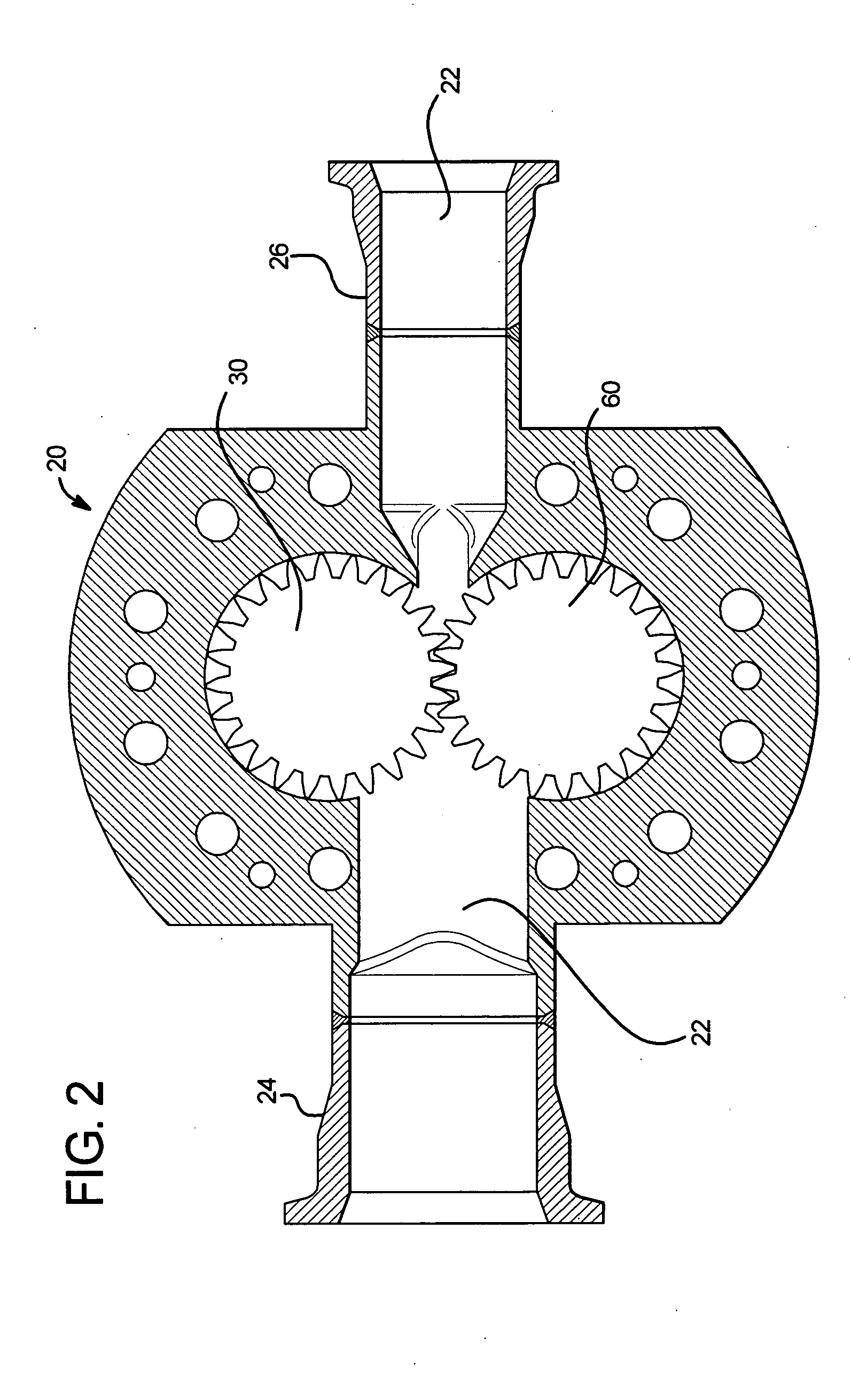

[0039]The present invention is generally directed to gear pumps and methods of using the gear pumps. In a general embodiment, the gear pump has its bearings placed outside of the product stream of the gear pump. The product can be any suitable flowable material such as, for example, a material having a high solids content. The bearings do not contact the product as it flows through the pump and therefore are not susceptible to wear and tear caused by the product, particularly by abrasive particles in the product. Additionally, the design of the gear pump in alternative embodiments makes the pump easy to clean, and therefore sanitary conditions can be maintained when using the pump. This provides an improved gear pump that allows for one or more of the following: 1) reduced maintenance costs, 2) reduced factory downtime, 3) operation at extremely high operating pressures and temperatures, 4) ability to handle viscous products, and 5) improved flow stability[\.\]

[0040]The gear pumps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com