Tank arrangement adapted for a submersible pump

a technology of submersible pumps and tanks, applied in the direction of floating buildings, self-bailing equipment/scuppers, vessel safety, etc., can solve the problems of unfavorable unfavorable air discharge, and inability to avoid air in the pump assembly, etc., to achieve simple yet effective air discharge, easy replacement, removal or servi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

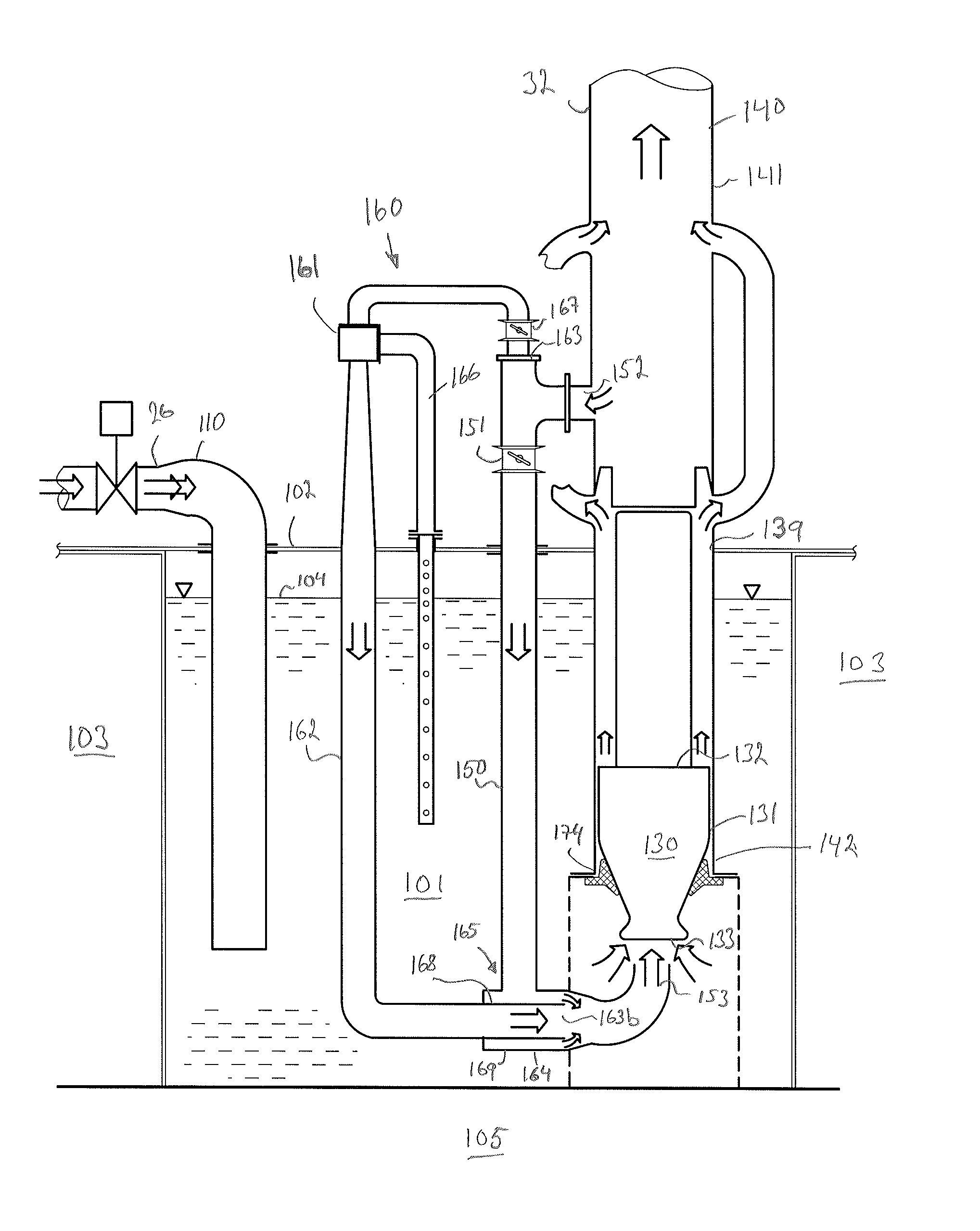

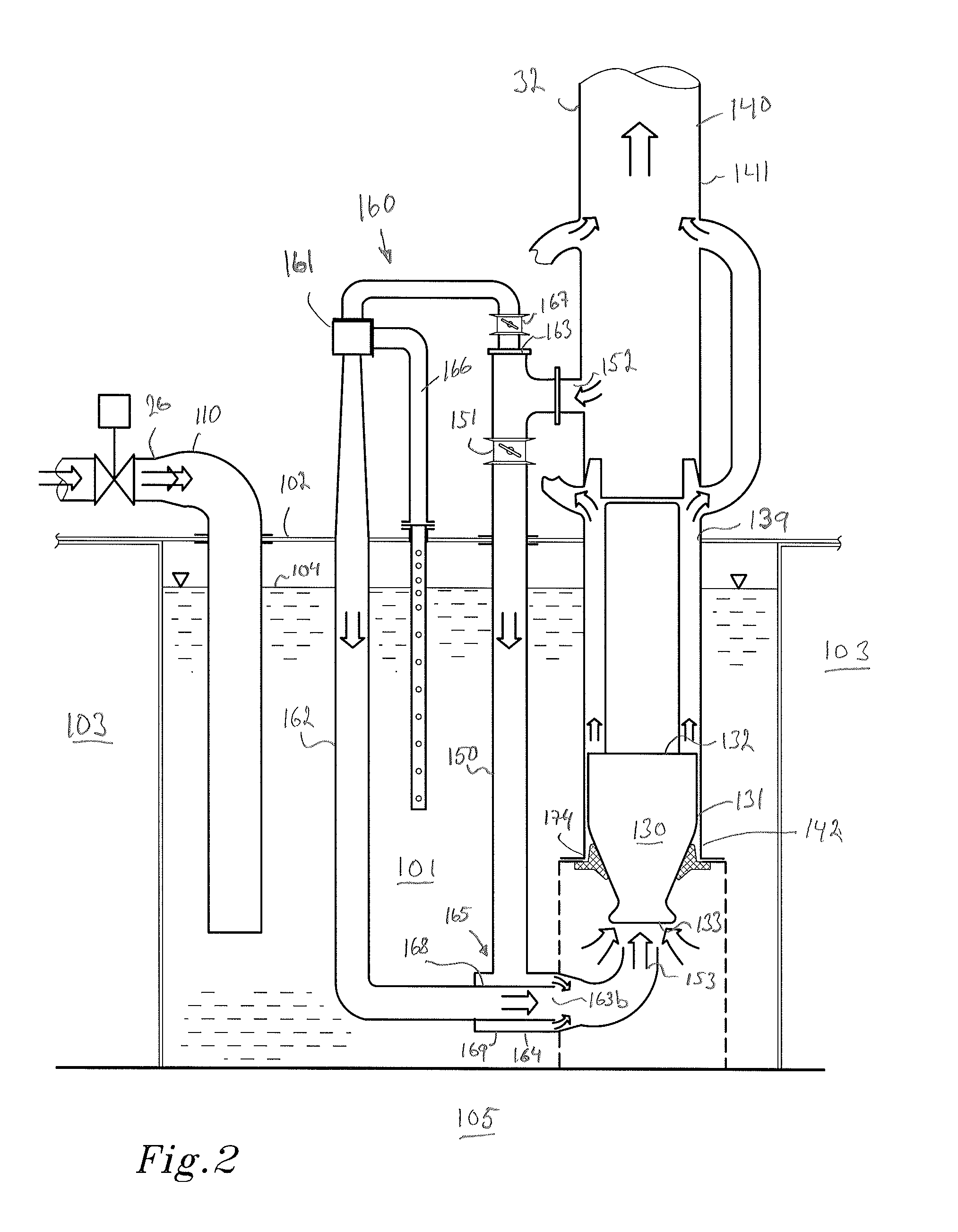

[0052]FIG. 3 shows a tank arrangement 100 according to the present invention. Similar features will be referred to with similar reference numbers. As is noticed, the opening adapted to receive the submersible pump 130 is not more than a recess 170 having a circular collar 171. The circular collar 171 is adapted to enable a seal between a reclosable lid 172 or optionally parts of the submersible pump 130. The reclosable lid 172 is resting on the circular collar 171.

[0053]The reclosable lid 172 enables an operator of a derrick 173 to remove or insert a submersible pump 130 through the outlet 139, into the recess 170 and thereby also into the storage space 101. A short caisson 140, as shown in FIG. 3, enables an operator to move the submersible pump 130 to an alternative or a second tank arrangement similar or different to the tank arrangement 100, according to the present invention, to a service station (not shown), or the like.

[0054]A water conduit 145 is arranged to the collar 171 o...

third embodiment

[0055]FIG. 4 shows a tank arrangement 100 according to the present invention. The tank arrangement 100 comprises as mentioned with reference to FIGS. 2 and 3, a storage space 101, at least one tank wall 102, at least one inlet for introducing bilge water, emergency bilge water or ballast water, a recess 170 for receiving a submersible pump 130 at a submersible pump position 131 and a reclosable lid 172.

[0056]The reclosable lid 172 is adapted to permit power and / or control cables 176 to the submersible pump 130 to extend there through or optionally via a cable connection on each side of the reclosable lid 172. The power and / or control cable 176 can however extend through any other wall of the tank arrangement 100. As is noticed in FIG. 4, the power and / or control cable 176 has a designated length, indicated by that the power and / or control cable 176 is illustrated in a serpentine like manner. By having a designated length of the power and / or control cable 176, the submersible pump 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com