Multiple Walled Primary Package with Phase Change Material

a phase change material and primary package technology, applied in the field of primary packages, receptacles or containers, can solve the problems of reducing the efficacy of compounds, reducing the work efficiency of workers, and reducing the cost of refrigeration, so as to improve the work efficiency, and improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

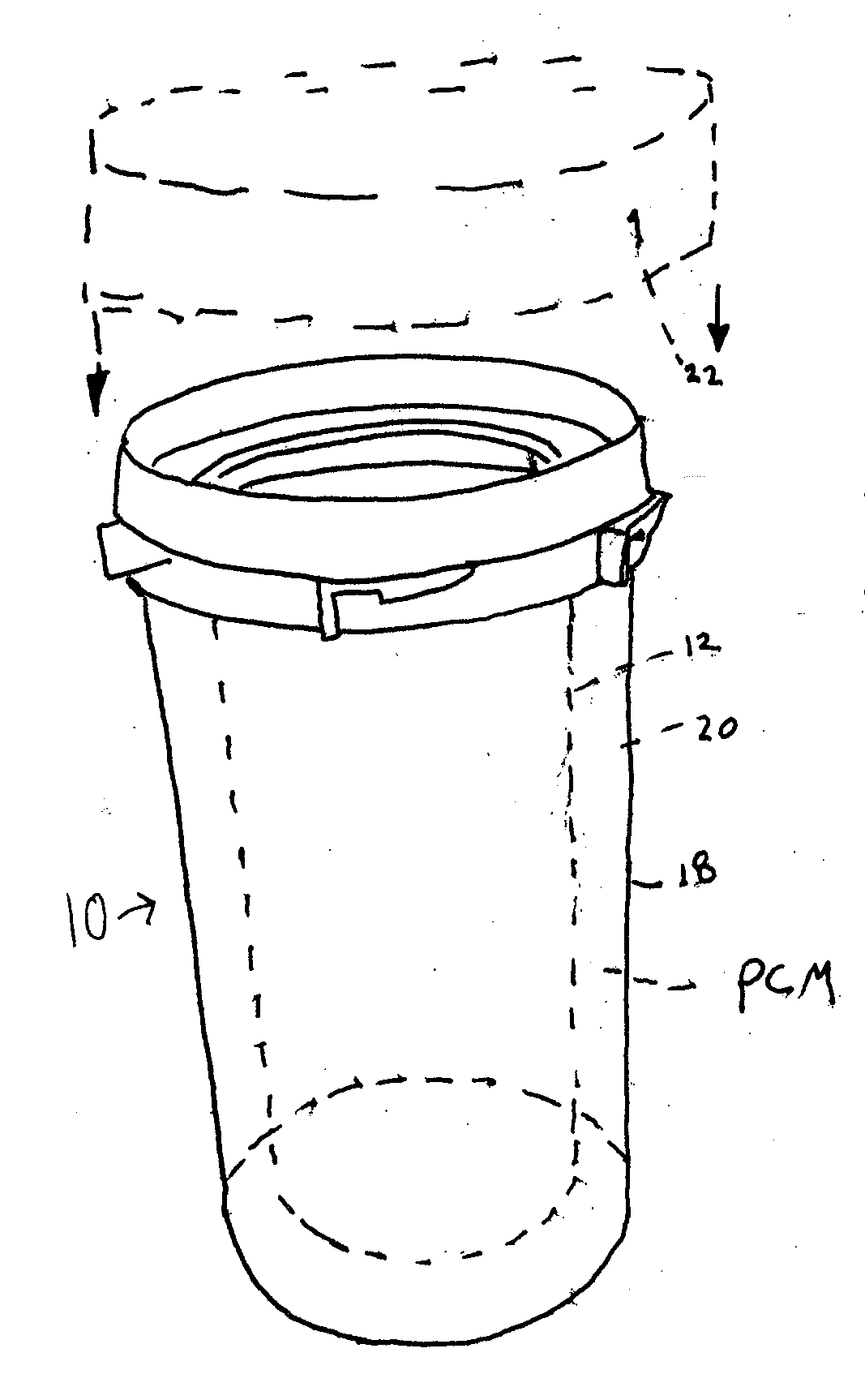

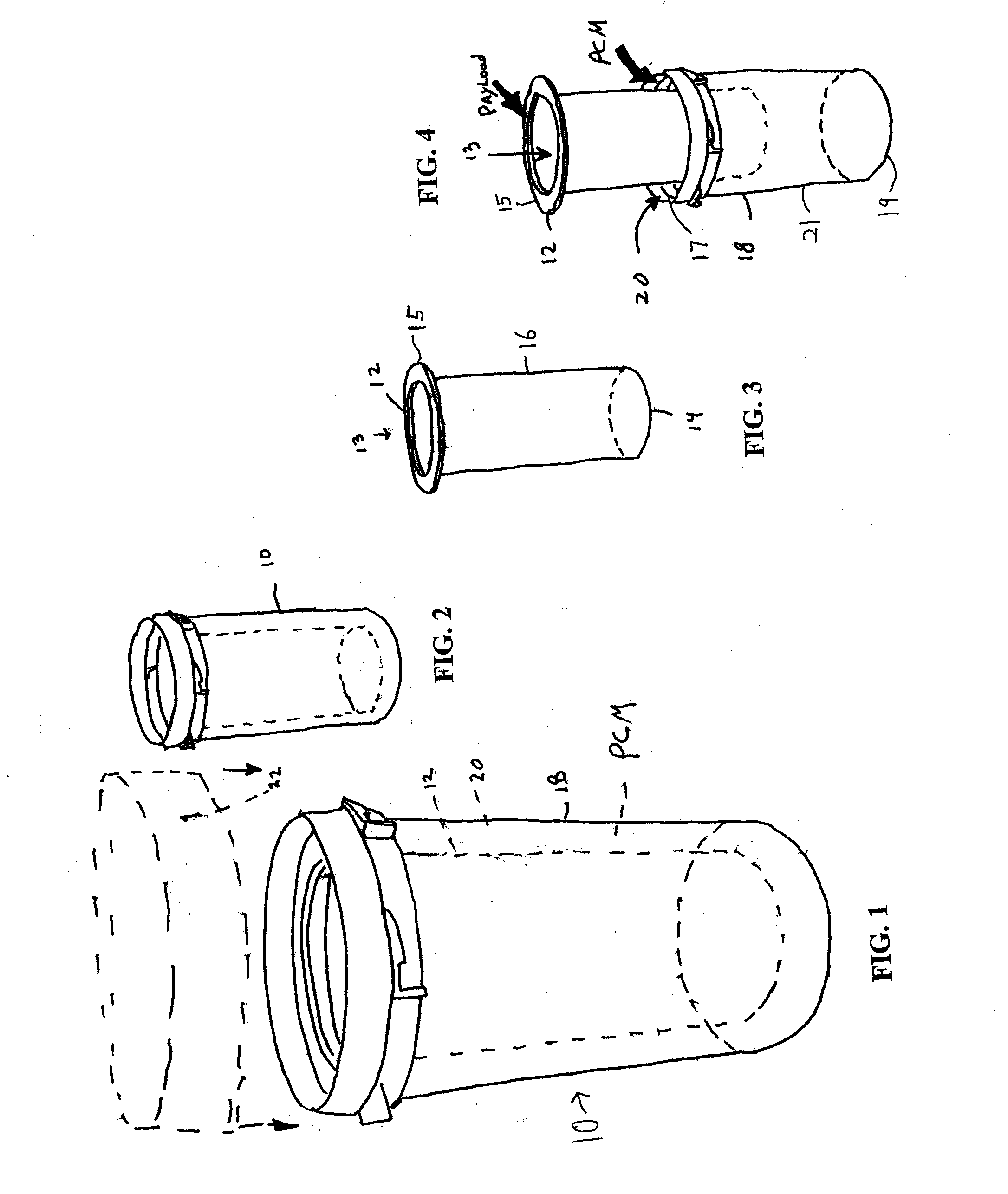

[0042]FIGS. 5-9 depict a container of the present invention. In this embodiment, two double-walled vessels, an inner vessel 32 and an outer shell 34, contain PCM. These two double-walled vessels together form container 30. FIG. 5 shows a perspective view, and FIG. 7 shows a cross-sectional view, of inner vessel 32. Inner vessel 32 includes an open upper end 36 and a closed lower end 38 connected by a hollow inner vessel wall 40. A rim 39 extends around the closed lower end 38. A PCM 42 is contained within the hollow inner vessel wall 40. Closed lower end 38 may also be comprised of a hollow panel containing a PCM.

[0043]FIG. 6 shows a perspective view, and FIG. 8 shows a cross-sectional view, of outer shell 34. Outer shell 34 includes a closed upper end 44 and an open lower end 46 connected by a hollow outer shell wall 48. A PCM 50 is contained within the hollow outer shell wall 48. Closed upper end 44 may also be comprised of a hollow panel containing a PCM. In this embodiment, PCM ...

third embodiment

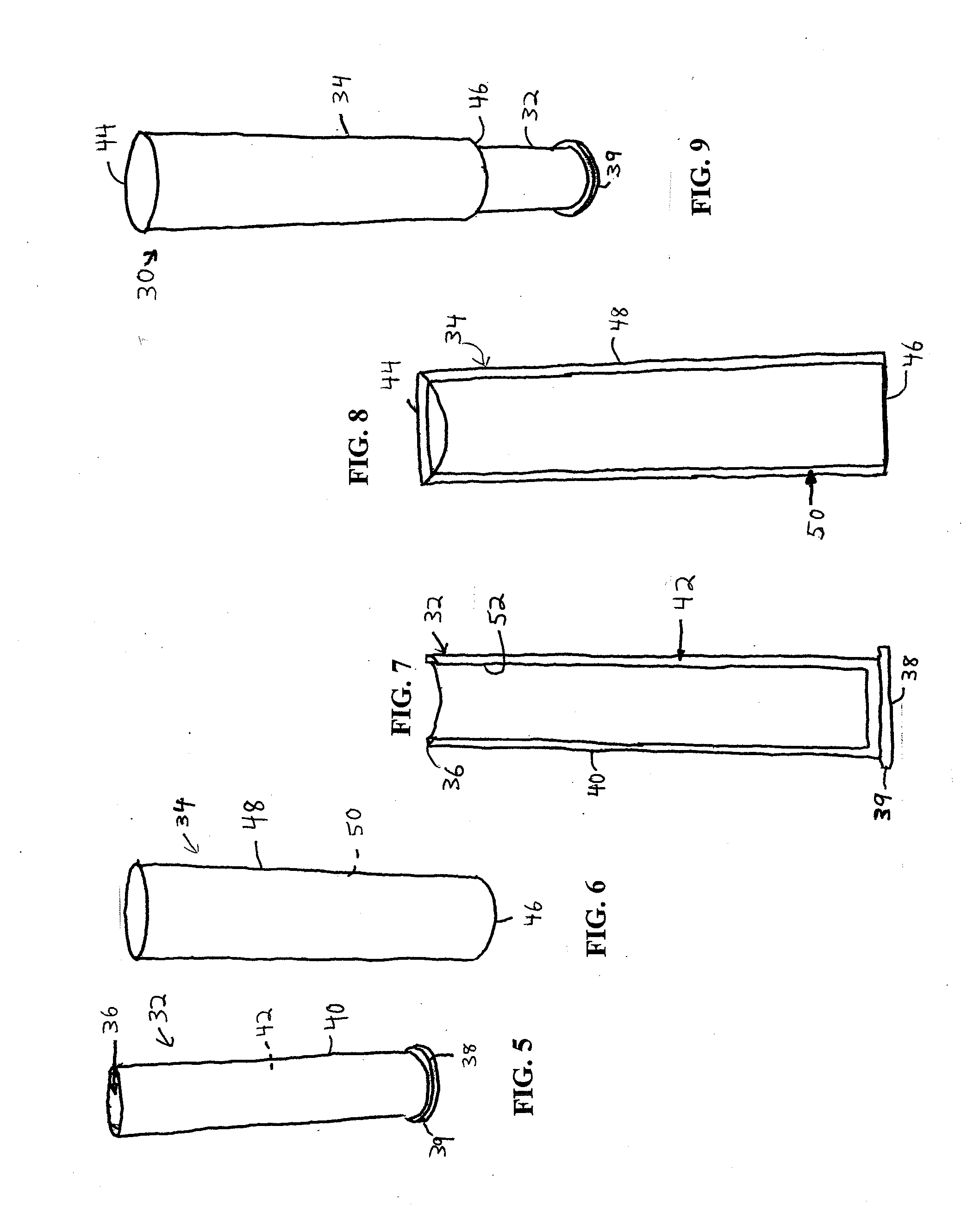

[0048]FIGS. 10-12 depict a container of the present invention. FIG. 12 depicts the assembled container 60, while FIG. 11 depicts a disassembled container 60. Container 60 includes a syringe 62 and an outer sleeve 64. As shown in FIG. 10, syringe 62 includes barrel 66, plunger 68, and needle 70. As shown in FIG. 11, the outer sleeve 64 includes an open upper end 72 and an open lower end 74 connected by a hollow outer sleeve wall 76. PCM 78 is contained within the hollow outer sleeve wall 76.

[0049]In the assembled container 60, the outer sleeve 64 surrounds the syringe barrel 66, such that the hollow outer sleeve wall 76 is in direct contact with the syringe barrel 66. In the embodiment shown in FIGS. 10-12, both ends of the outer sleeve 64 are open, enabling the syringe 62 to be used while contained within the outer sleeve 64. However, in other embodiments, the outer sleeve 64 may include a closed end. If the outer sleeve 64 includes a closed end, the syringe barrel 66 can be stored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com