Self-pumping liquid and gas cooling system for the cooling of solar cells and heat-generating elements

a solar cell and gas cooling system technology, applied in indirect heat exchangers, lighting and heating apparatus, heat exchangers, etc., can solve problems such as adverse effects, and achieve the effect of high efficiency and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

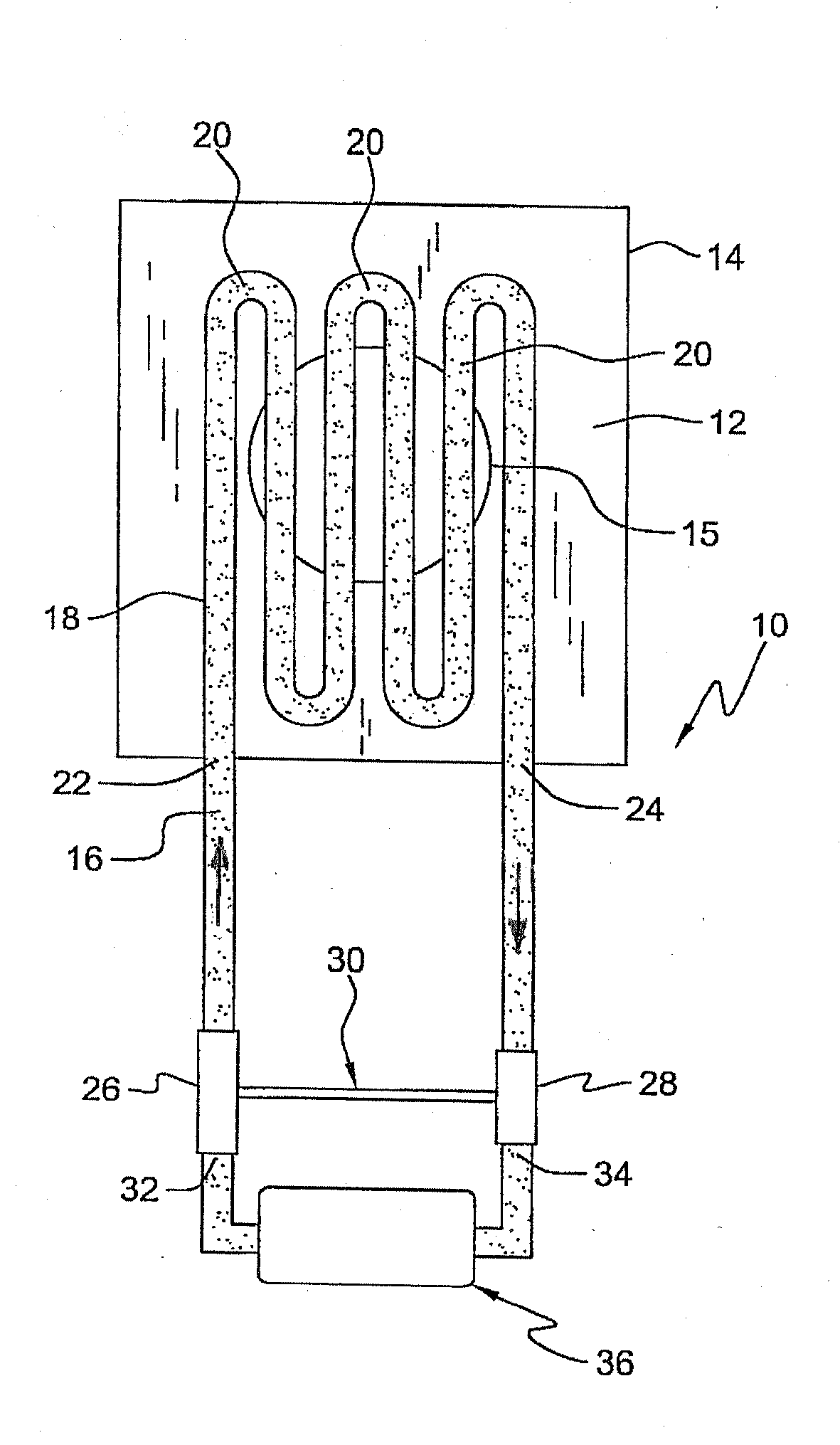

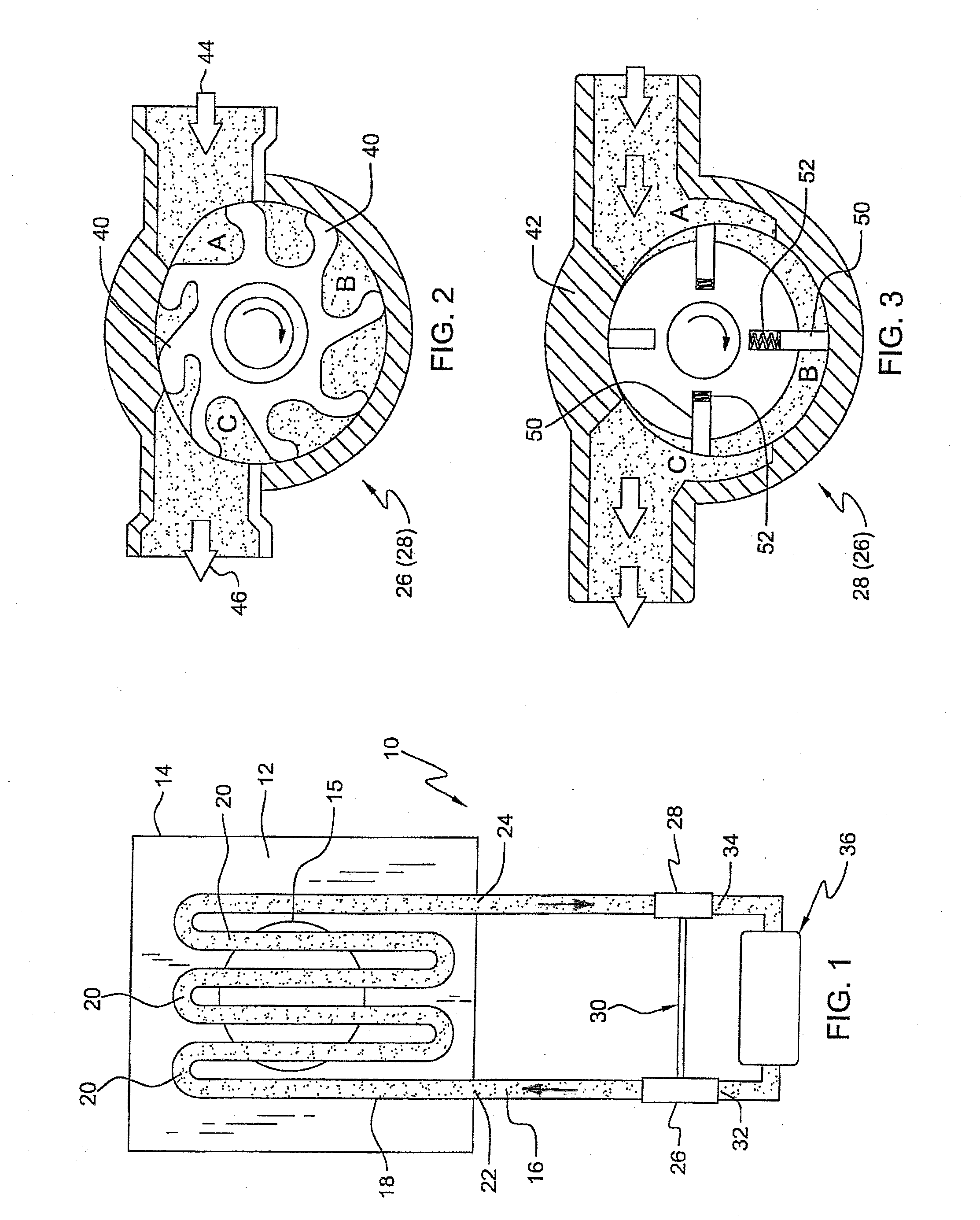

[0016]Referring specifically to the closed coolant system pursuant to the invention, as illustrated in FIG. 1, there is represented a cooling system 10 that includes a heat exchanger which may be constituted of an enclosed housing structure 14 and has a tubing arrangement 18 therein containing or filled with either water or any suitable coolant 16, for example, such as methanol or a coolant solution marketed by 3M Corporation under the designation HFE-7000. In this connection, methanol is particularly suitable when maintained under an operating pressure of about 100 mm Hg. It is also possible to employ ammonia as a coolant, but may be somewhat hazardous to use unless the system is generated remotely from population centers.

[0017]Traversing the heat exchanger 12 is the closed-cycle tubing or piping system 18 of which coils or loops 20 meander therethrough, as illustrated in the drawing. The tubing may be embedded in an array of copper fins, which conduct heat to air, which may includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com