Controller for engine cooling system

a technology for controlling a cooling system and an engine, which is applied in the direction of machines/engines, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of frequent stop and restart of equipped engines, deterioration of fuel consumption efficiency, and above problems, so as to achieve sufficient heating and increase the air temperature through the second exchanging portion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

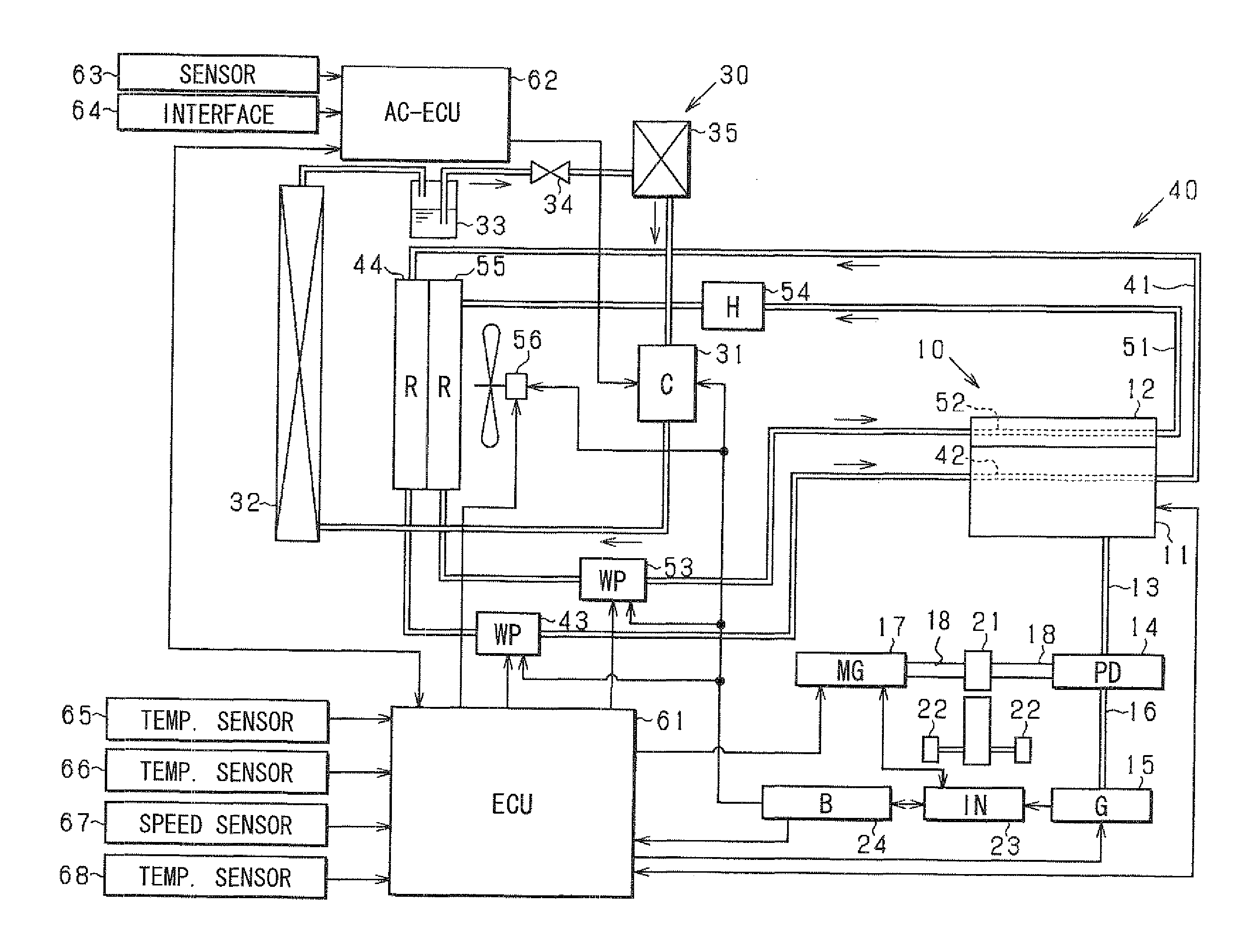

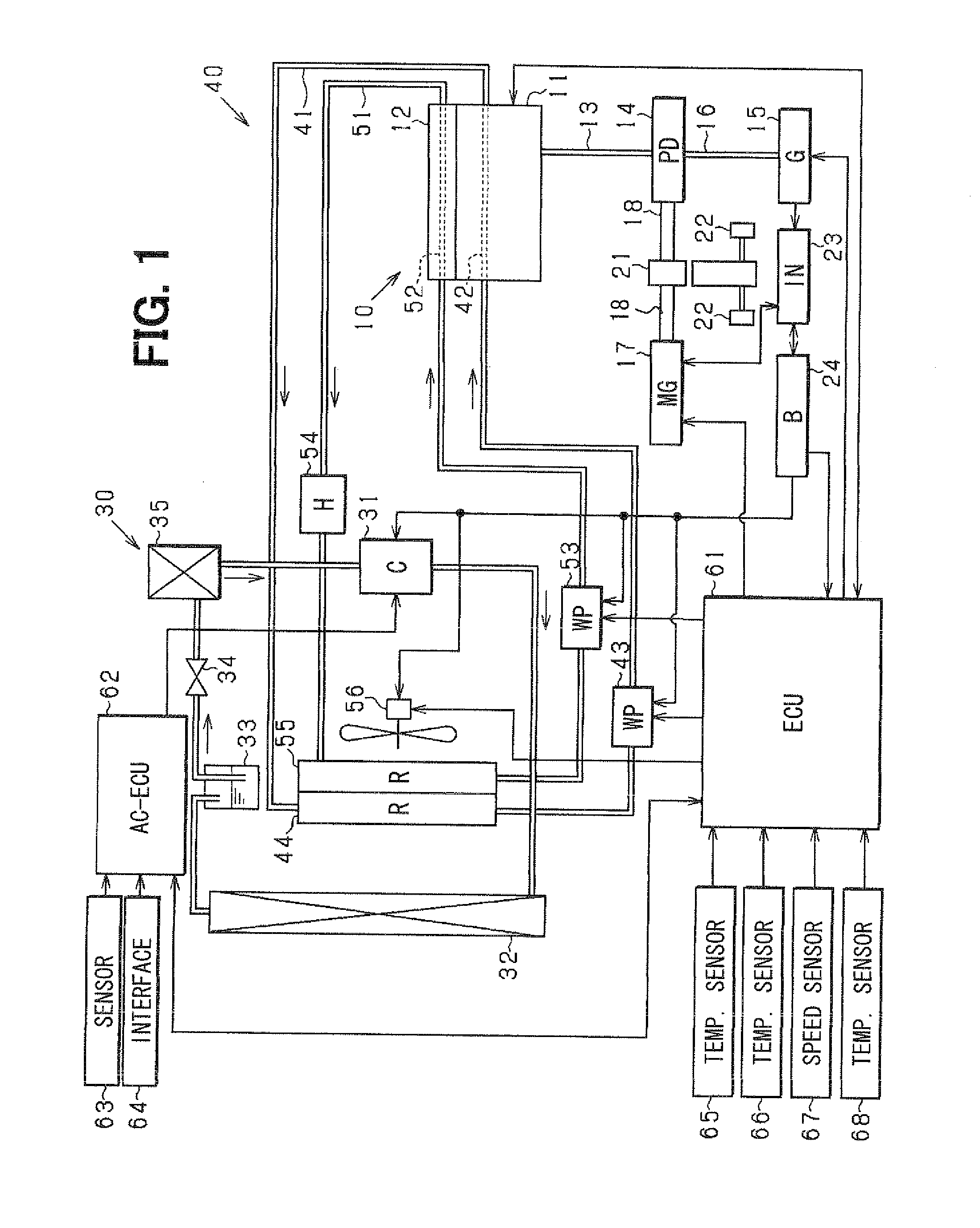

[0044]Hereinafter, a first embodiment that embodies the present invention will be described with reference to the drawings. In the present embodiment, a vehicle is equipped with a hybrid engine. FIG. 1 schematically shows an entire configuration of a control system in a first embodiment.

[0045]A vehicle is equipped with an internal combustion engine 10. The engine 10 is comprised of a cylinder block 11 and a cylinder head 12. The cylinder block 11 has a cylinder (not shown) in which a piston is slidably provided. The cylinder head 12 is provided on the cylinder block 11 to define a combustion chamber.

[0046]When air-fuel mixture is combusted in the combustion chamber, the piston slides downward. An output shaft 13 of the engine 10 is connected to a power distribution portion 14. The power distribution portion 14 has a planetary gear mechanism including a planetary gear, a sun gear and a ring gear. The planetary gear is connected to the output shaft 13 of the engine 10, the sun gear is...

second embodiment

[0113]As shown in FIG. 8A, the cylinder-block-passage and the cylinder-head-passage can be combined as one passage.

[0114]Specifically, a flow rate control valve 73 is disposed at a branch portion of the water jackets 42, 52. According to control signals from the ECU 61, the flow rate control valve 73 controls the flow rate of engine coolant flowing through each water jacket 42, 52. A water temperature sensor is provided to each of outlets of the water jackets 42, 52 to detect the head-coolant temperature “Thead” and the block-coolant temperature “Tblock”. The ECU 61 controls the water pump 72 and the flow rate control valve 73 in order to control the head-coolant temperature “Thead” and the block-coolant temperature “Tblock”.

[0115]A thermostat 74 is provided in the coolant passage. A bypass passage 75 is provided which bypasses the radiator 71. When the engine coolant temperature is low, the engine coolant flows through the bypass passage 75. The thermostat 74 is a well known mechan...

third embodiment

[0125]FIG. 9 schematically shows an entire structure of an air conditioner according to third embodiment. An air-conditioner is provided to a hybrid vehicle.

[0126]The air-conditioner 101 is provided with a first coolant circuit 110 and a second coolant circuit 120. The engine coolant passed through a cylinder head 131 flows in the first coolant circuit 110. The first coolant circuit 110 includes a first heater core 111, a first water pump 112, and a first temperature sensor 113. The engine coolant passed through a cylinder block 132 flows in the second coolant circuit 120. The second coolant circuit 120 includes a second heater core 121, a second water pump 122, and a second temperature sensor 123.

[0127]A cylinder block 132 and a cylinder head 131 of the engine 130 have well-known configuration.

[0128]The cylinder head 131 has a first coolant inlet 131a and a first coolant outlet 131b. The engine coolant flows through a coolant passage formed in the cylinder head 131. The coolant flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com