Energy recovery system for an internal combustion engine

a technology for energy recovery and internal combustion engines, which is applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of reducing the benefits of the system, requiring space for the heat exchanger arranged in the exhaust gas line, and bringing weight and cost, so as to improve energy recovery, reduce costs, and make the system lighter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

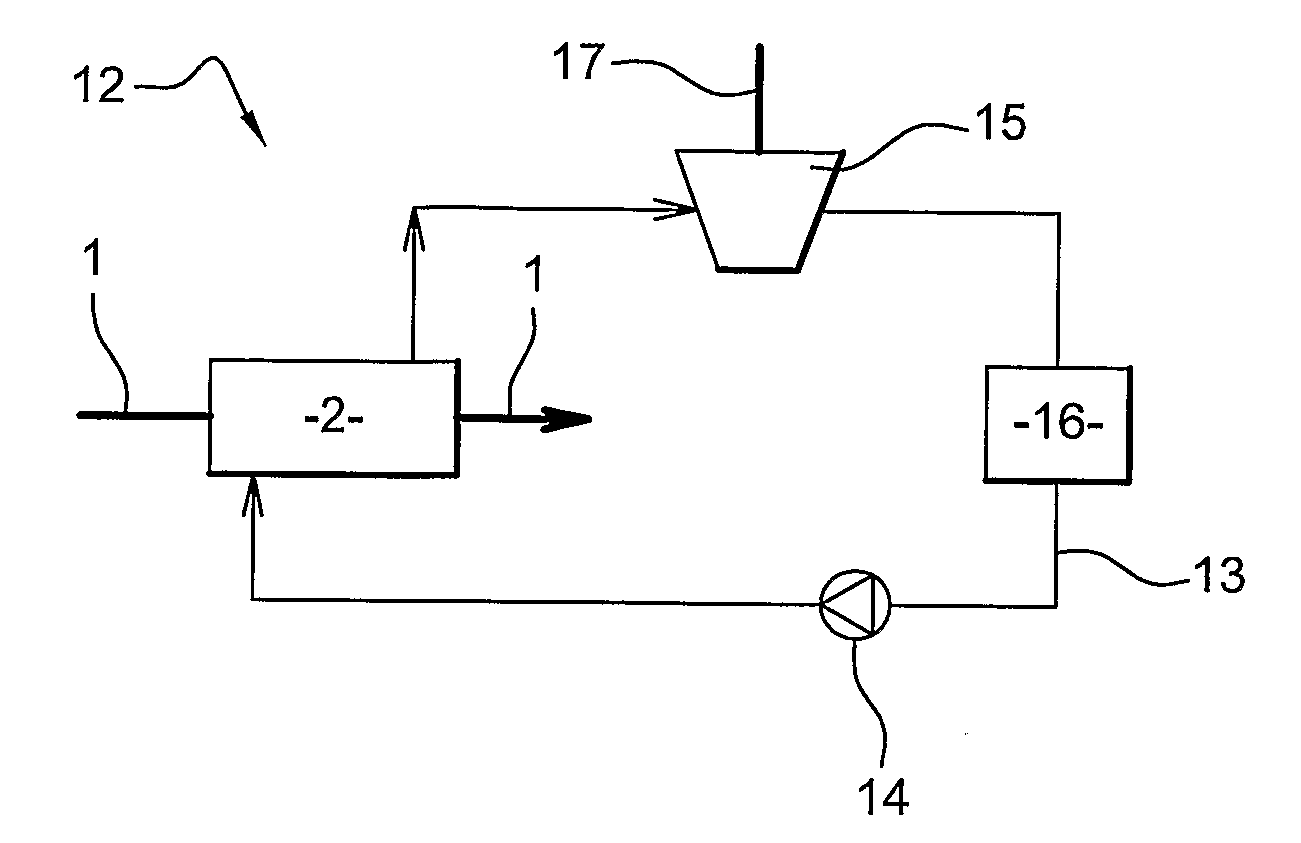

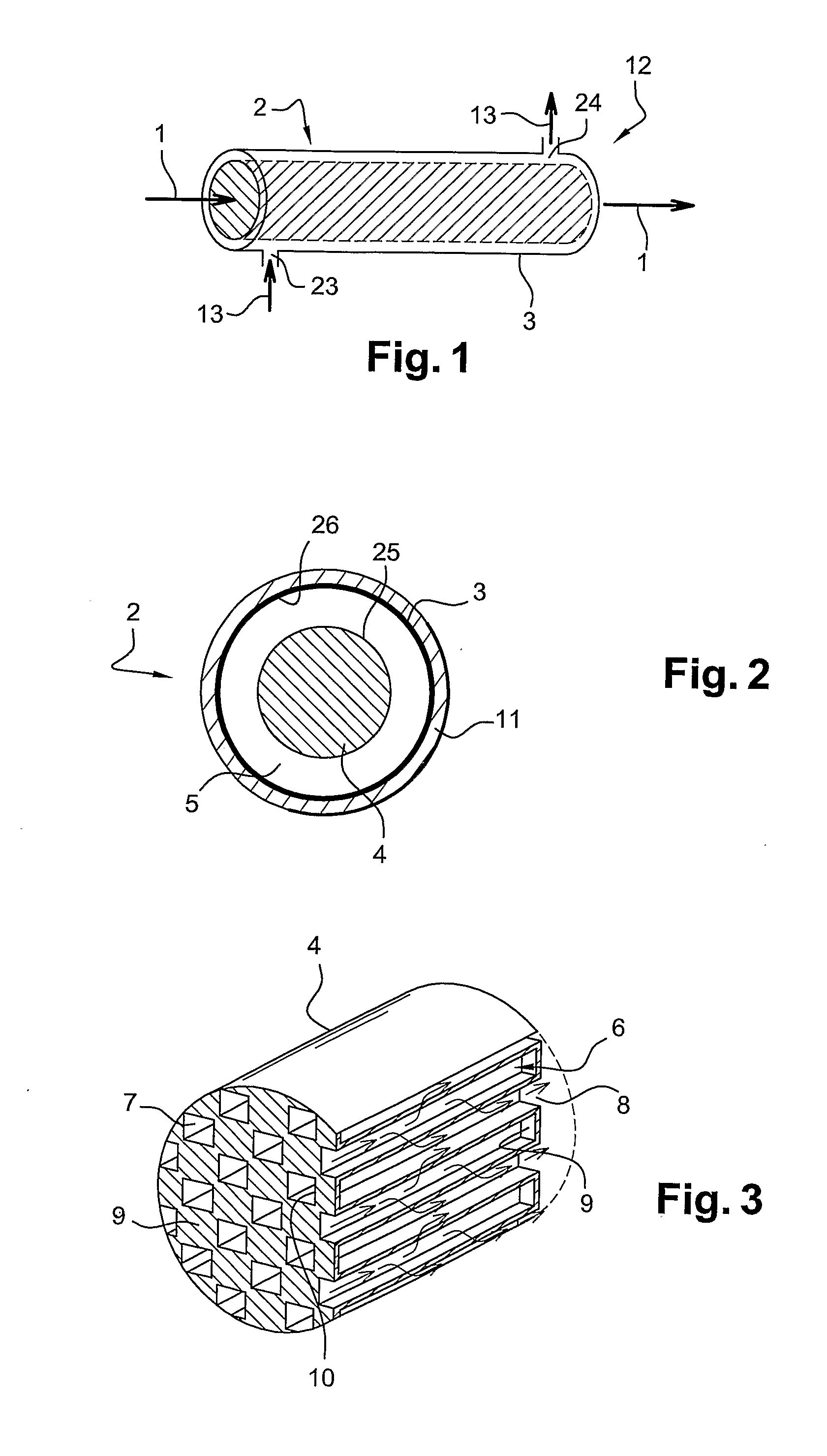

[0043]A first embodiment is illustrated in FIG. 4.

[0044]In this embodiment, the secondary line is a closed loop forming a Rankine thermodynamic cycle.

[0045]Water (or another liquid, such as an organic fluid) is moved by means of a pump 14 in said secondary line 13, and enters the particulate filter 2, in which said water is evaporated into steam (or another corresponding gas), thanks to the heat received from the exhaust gas. Said particulate filter 2 therefore works as an evaporator. The steam going out of said particulate filter 2 is then expanded in a turbine 15 located downstream from said particulate filter 2. The expanded steam is then condensed into water in a condenser 16 located downstream from said turbine 15, said water being again directed towards the particulate filter 2 by means of the pump 14.

second embodiment

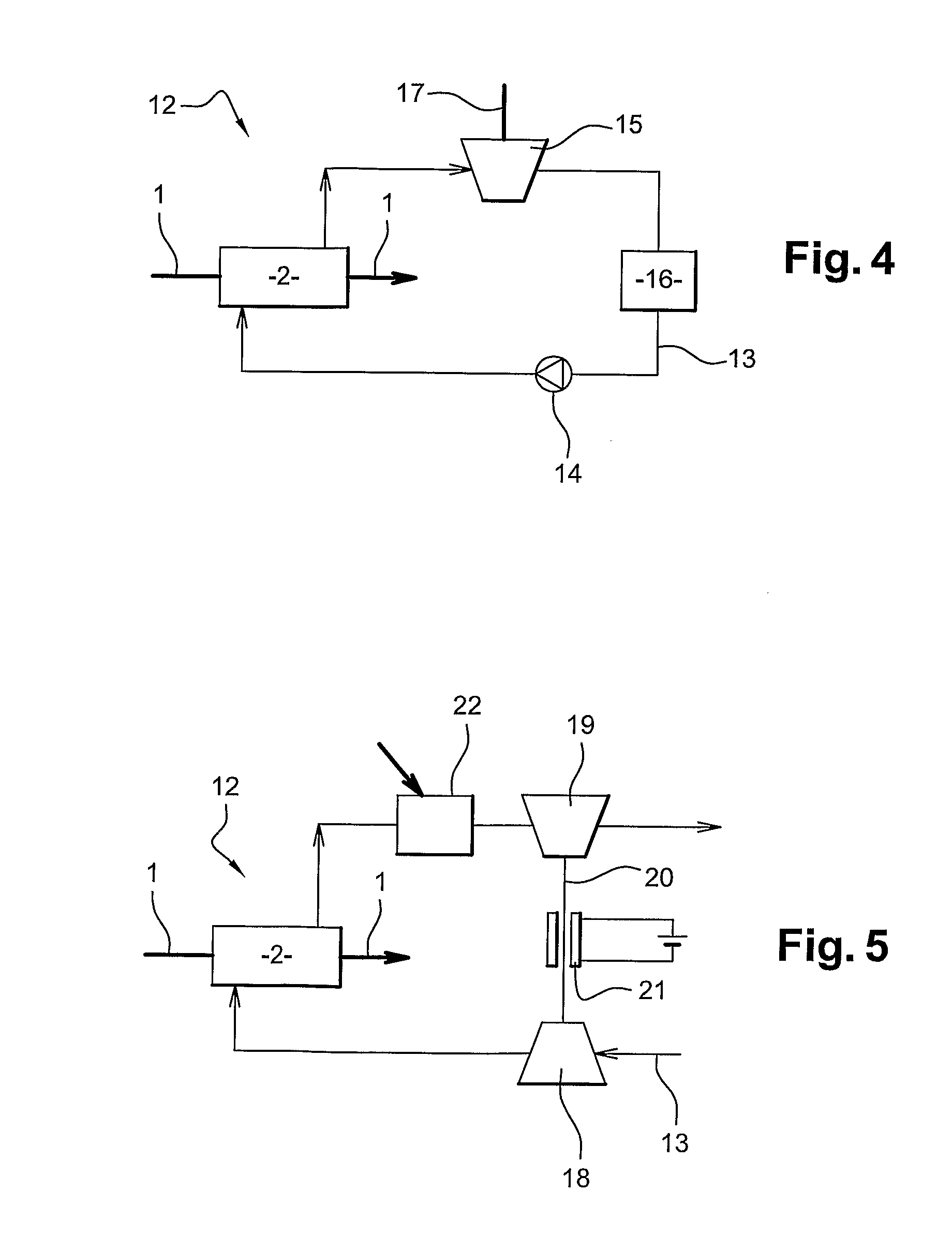

[0046]In this embodiment, the heat of exhaust gases is recovered into work on the turbine shaft 17. A second embodiment is illustrated in FIG. 5.

[0047]In this embodiment, the secondary line is an open loop forming a Brayton thermodynamic cycle. A gas, for example ambient air, is first compressed in a compressor 18 located upstream from said particulate filter 2, then passes through the heat exchanging area 5 of the particulate filter 2 acting as a heat exchanger, where said air is heated by the hot exhaust gases. Downstream from said particulate filter 2, heated air reaches a turbine 19 where it is expanded, thereby transforming the energy conveyed by the air into mechanical energy.

[0048]Turbine 19 is mechanically connected to compressor 18 by means of a shaft 20. The energy produced by the warm air expansion is recovered into mechanical energy on said shaft 20. Said energy is partially used to operate compressor 18.

[0049]The system may further comprise an alternator 21 designed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com