Closed-loop control of cmp slurry flow

a closed-loop control and slurry technology, applied in the direction of grinding machine components, manufacturing tools, lapping machines, etc., can solve the problems of polishing pad efficiency change, polishing pad eventually needs replacement, etc., and achieve the effect of reducing the thickness of the polishing pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

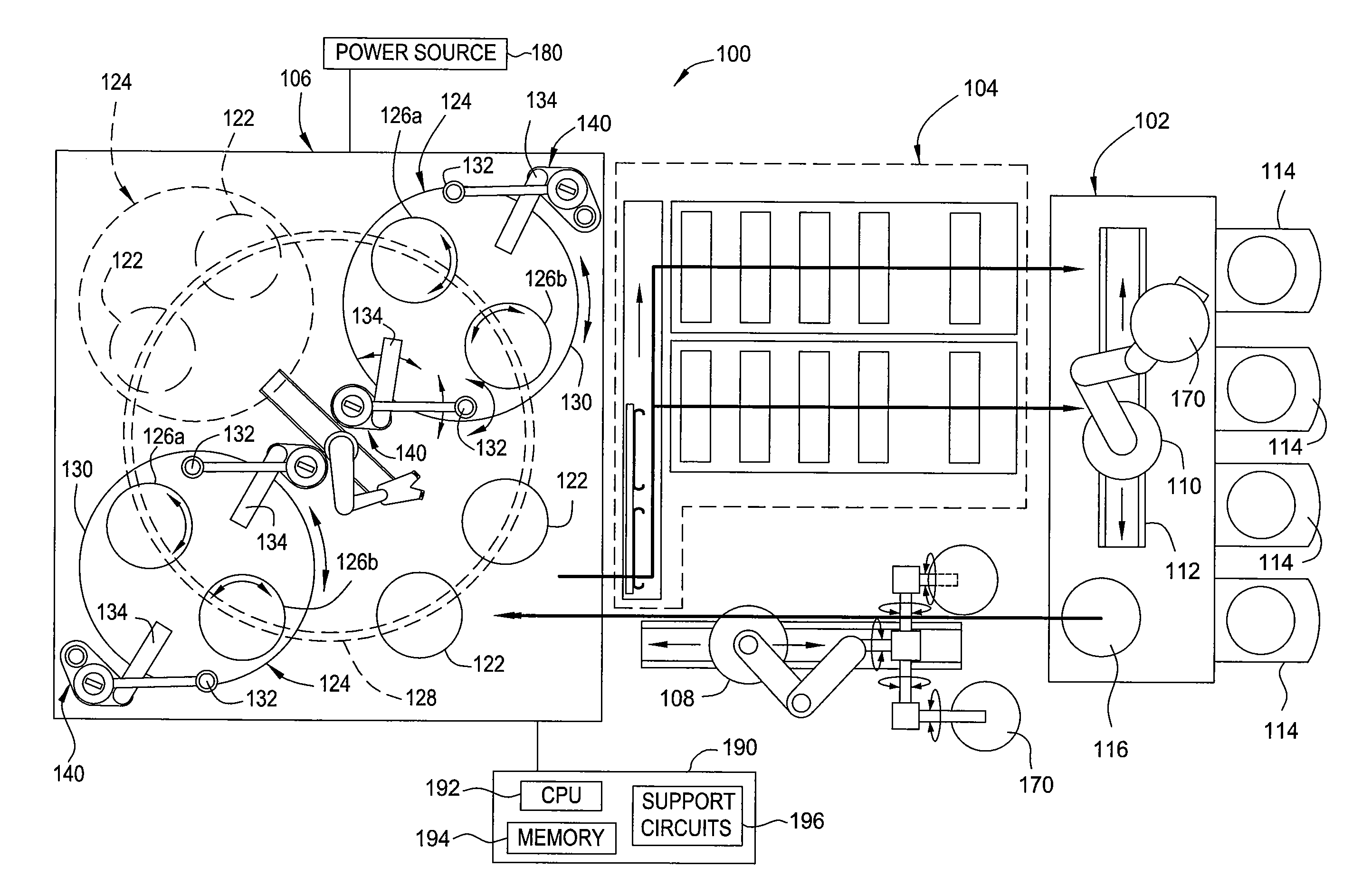

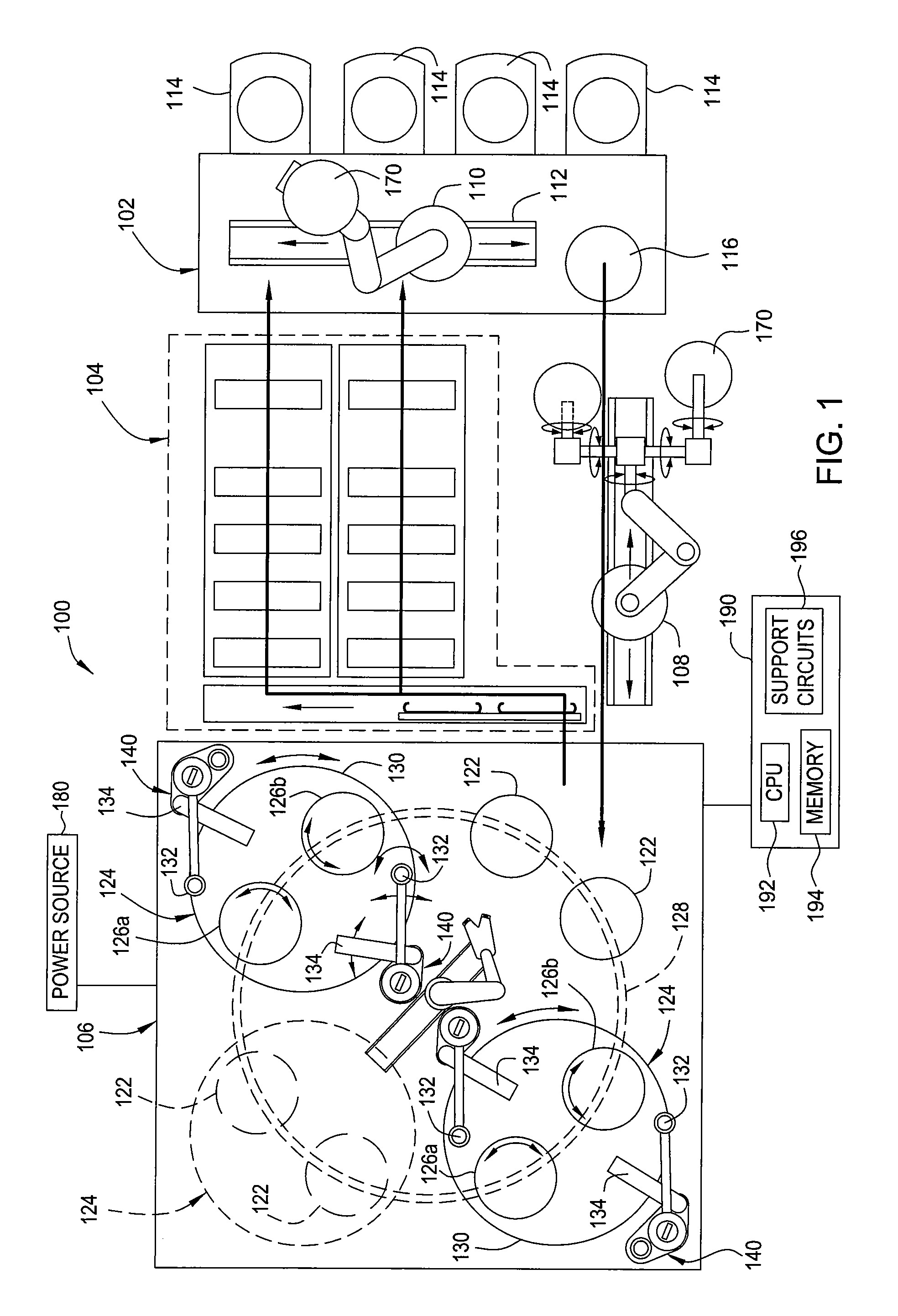

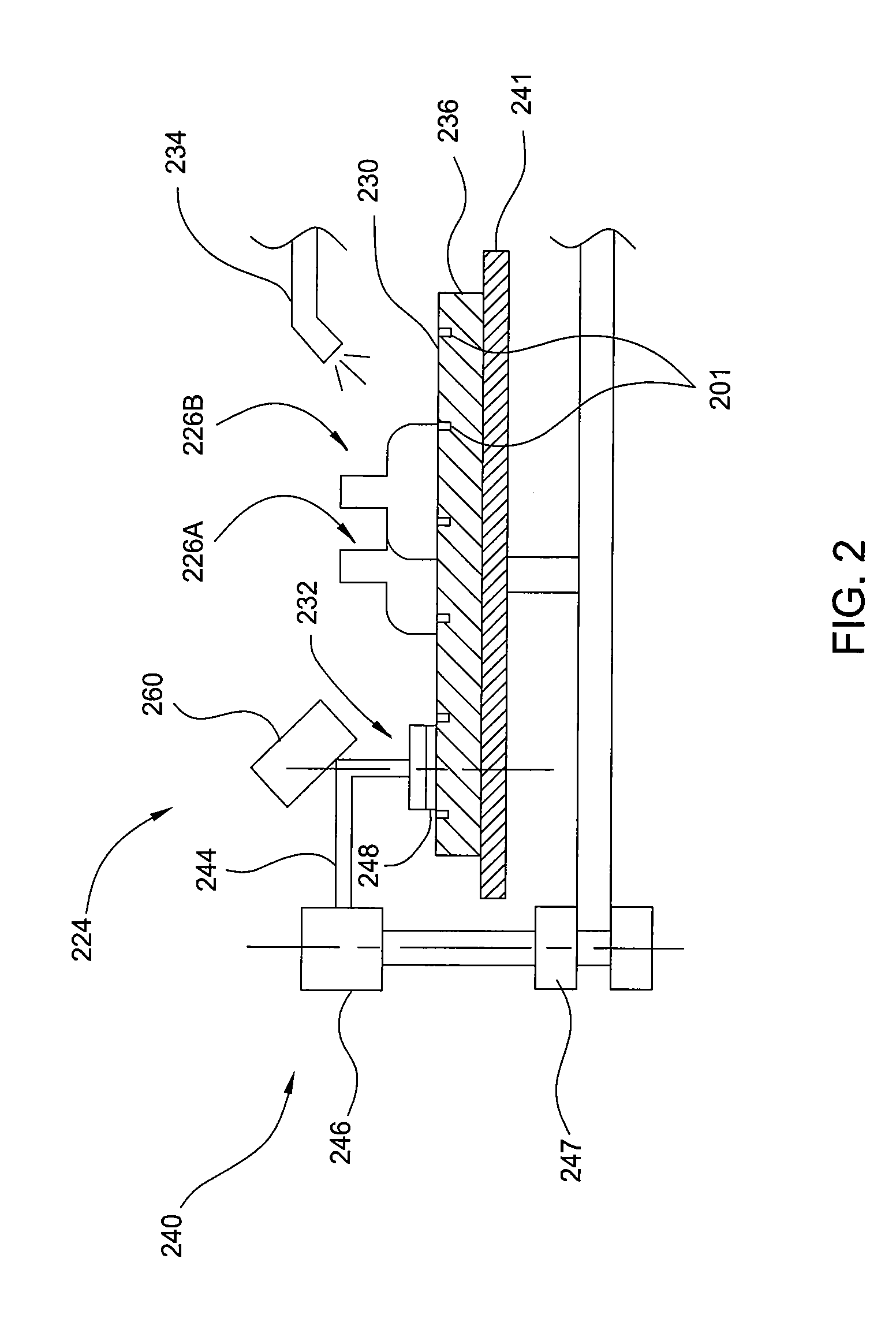

[0018]Embodiments of the present invention generally relate to methods for chemical mechanical polishing a substrate. The methods generally include measuring the thickness of a polishing pad having grooves or other slurry transport features on a polishing surface. Once the depth of the grooves on the polishing surface is determined, a flow rate of a polishing slurry is adjusted in response to the determined groove depth. A predetermined number of substrates are polished on the polishing surface. The method can then optionally be repeated.

[0019]While the particular apparatus in which the embodiments described herein can be practiced is not limited, it is particularly beneficial to practice the embodiments in a REFLEXION GT™ system, REFLEXION® LK CMP system, and MIRRA MESA® system sold by Applied Materials, Inc., of Santa Clara, Calif. Additionally, CMP systems available from other manufacturers may also benefit from embodiments described herein.

[0020]FIG. 1 is a top schematic view il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com