Ventilated mattress cover

a mattress cover and ventilation technology, applied in the field of fitted mattress covers, can solve the problems of inability to wash the cover easily, difficult to handle, and only clean the product, and achieve the effects of convenient cleaning, convenient use, and convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

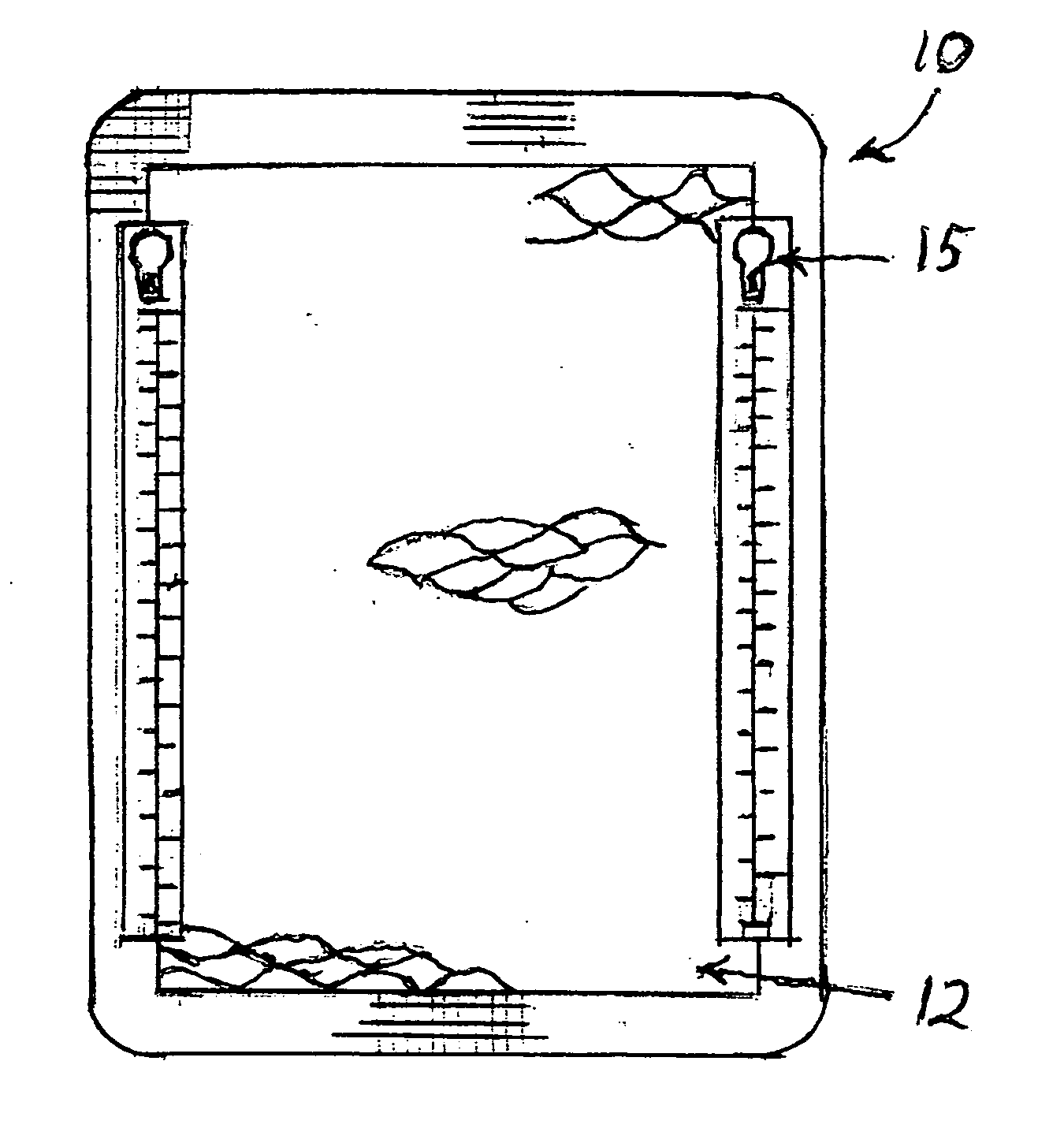

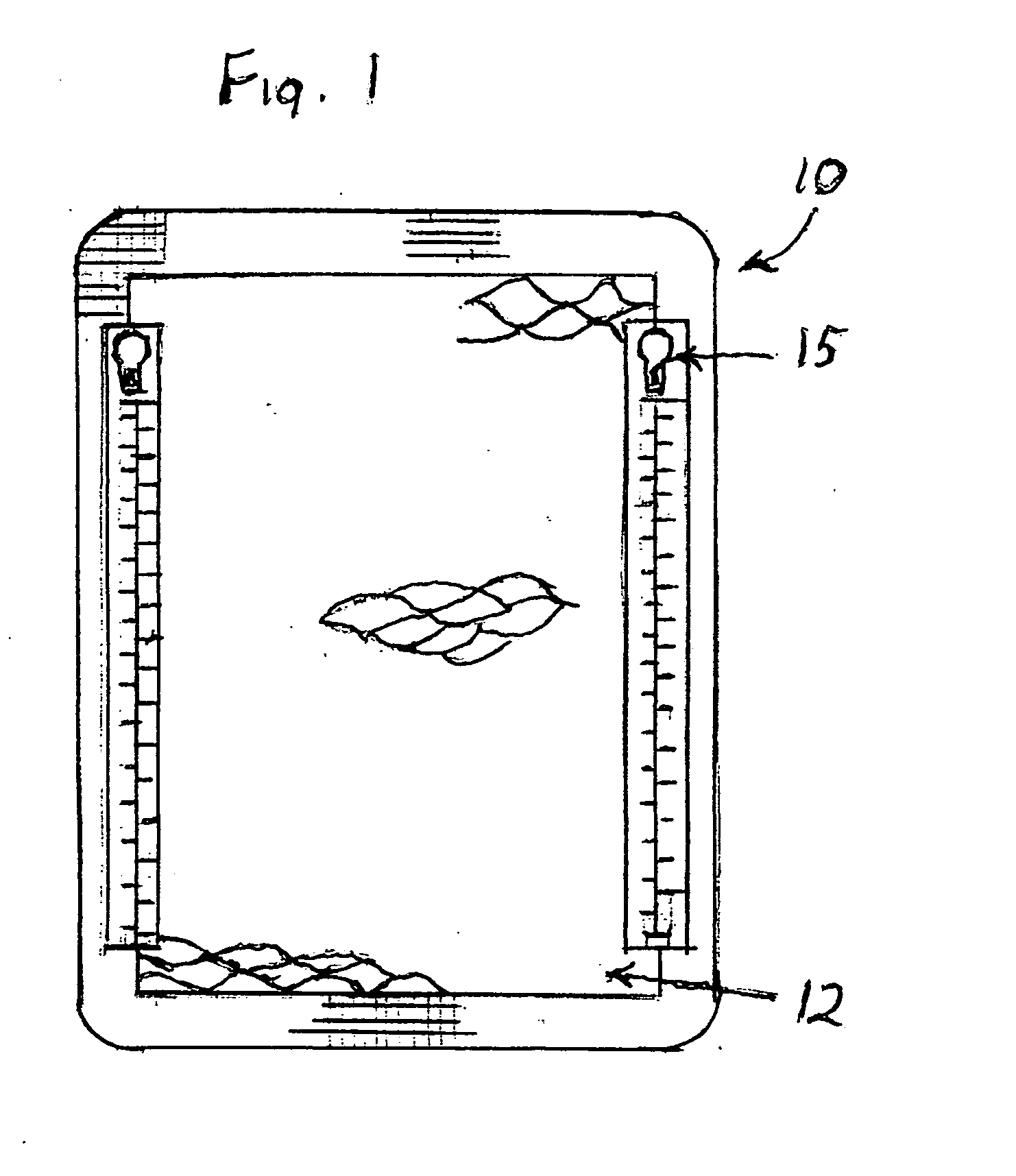

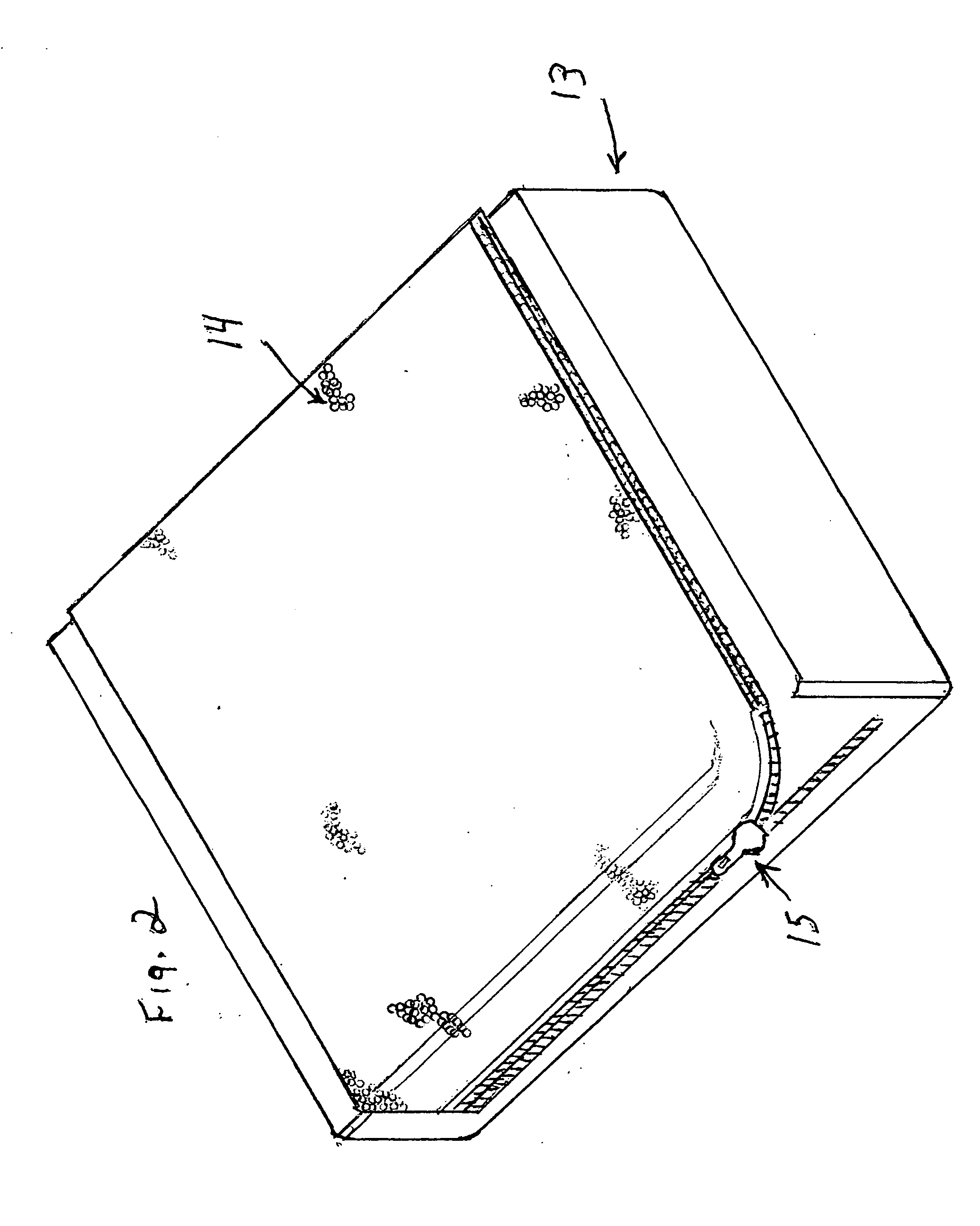

[0020]A preferred embodiment of a ventilated mattress cover according to this invention is indicated generally in FIG. 1. The ventilated cover is particularly constructed to be attached to a fitted (10) bed sheet or fitted mattress cover or (13) mattress with a brass zipper. The spacer fabric layers (11,12) are permanently sewed together and provide ventilation and pressure reduction, however, it could also be integrated (FIG. 2) as part of a (13) manufactured mattress and attached with a zipper along the sides of the (FIG. 2) mattress. When placed on a (13) mattress the body weight of the occupant does not totally collapse the (12) large holed spacer fabric (generally between 5-20 mm thick). The (12) spacer fabric maintains an air pathway or duct to the room air. This duct transfers the warmer moist air generated by the occupant out into the room air. The heat and moisture first pass thru the (10) sheet and (11) wicking layer or small hole (2-3 mm diameter) spacer fabric by conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com