Exhaust line for a motor vehicle with a closed recovery cycle for exhaust gas heat energy, and associated control method

a technology of exhaust gas and heat energy recovery, which is applied in the field of recovery of energy in motor vehicle exhaust lines, can solve the problems of significant loss of heat energy recovery yield from exhaust gases, risk of unpriming the closed cycle for recovering heat energy, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

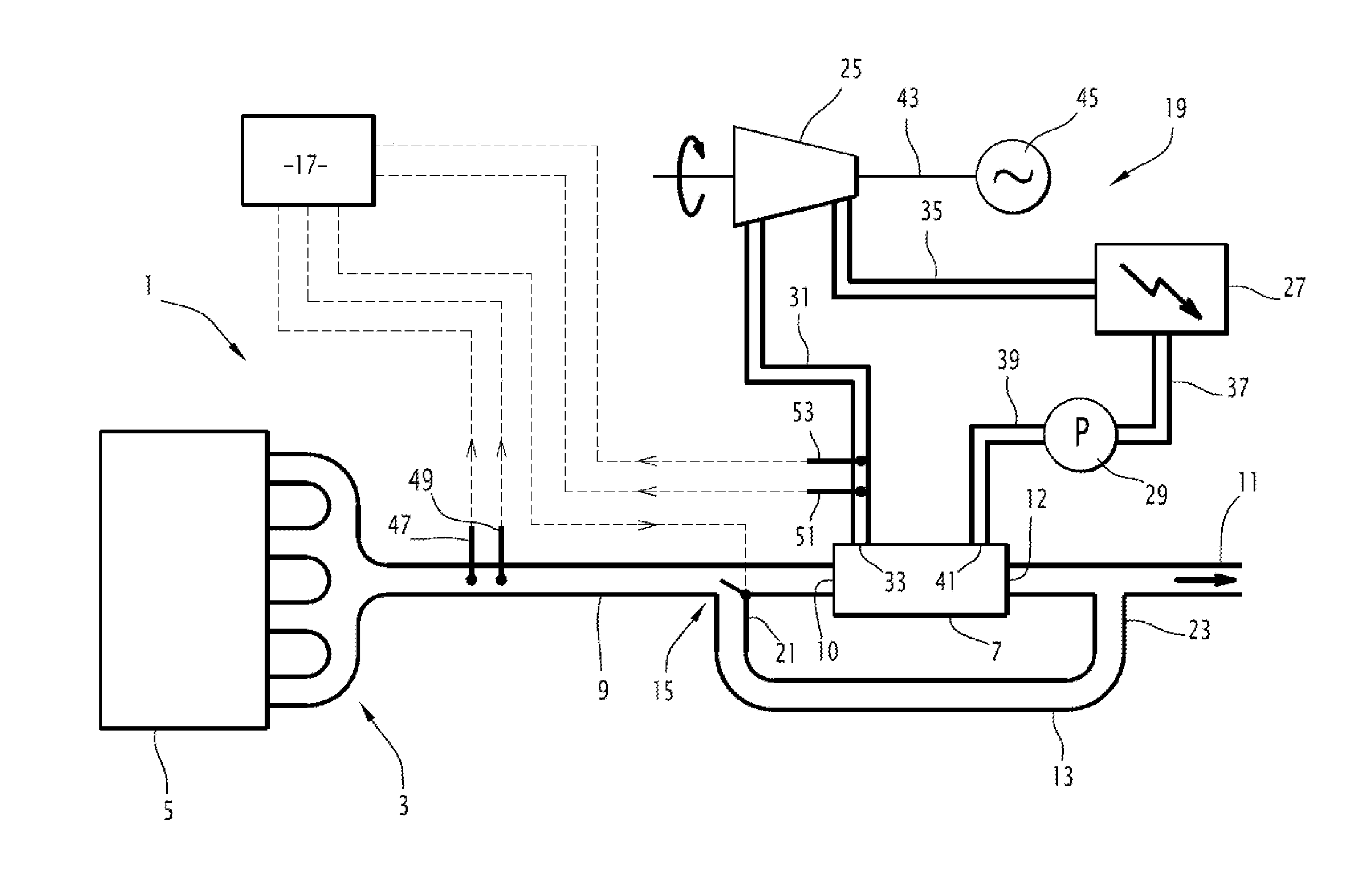

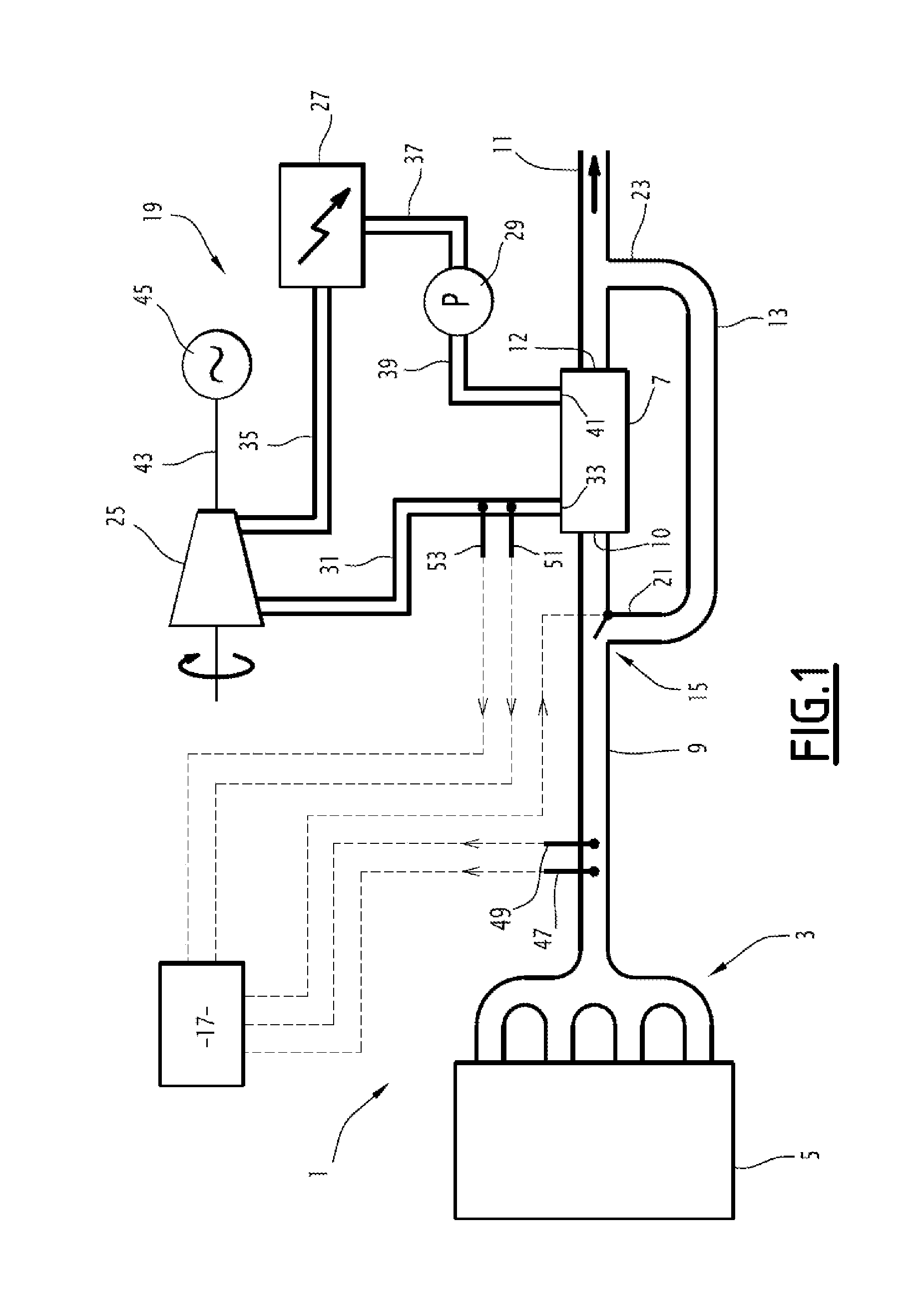

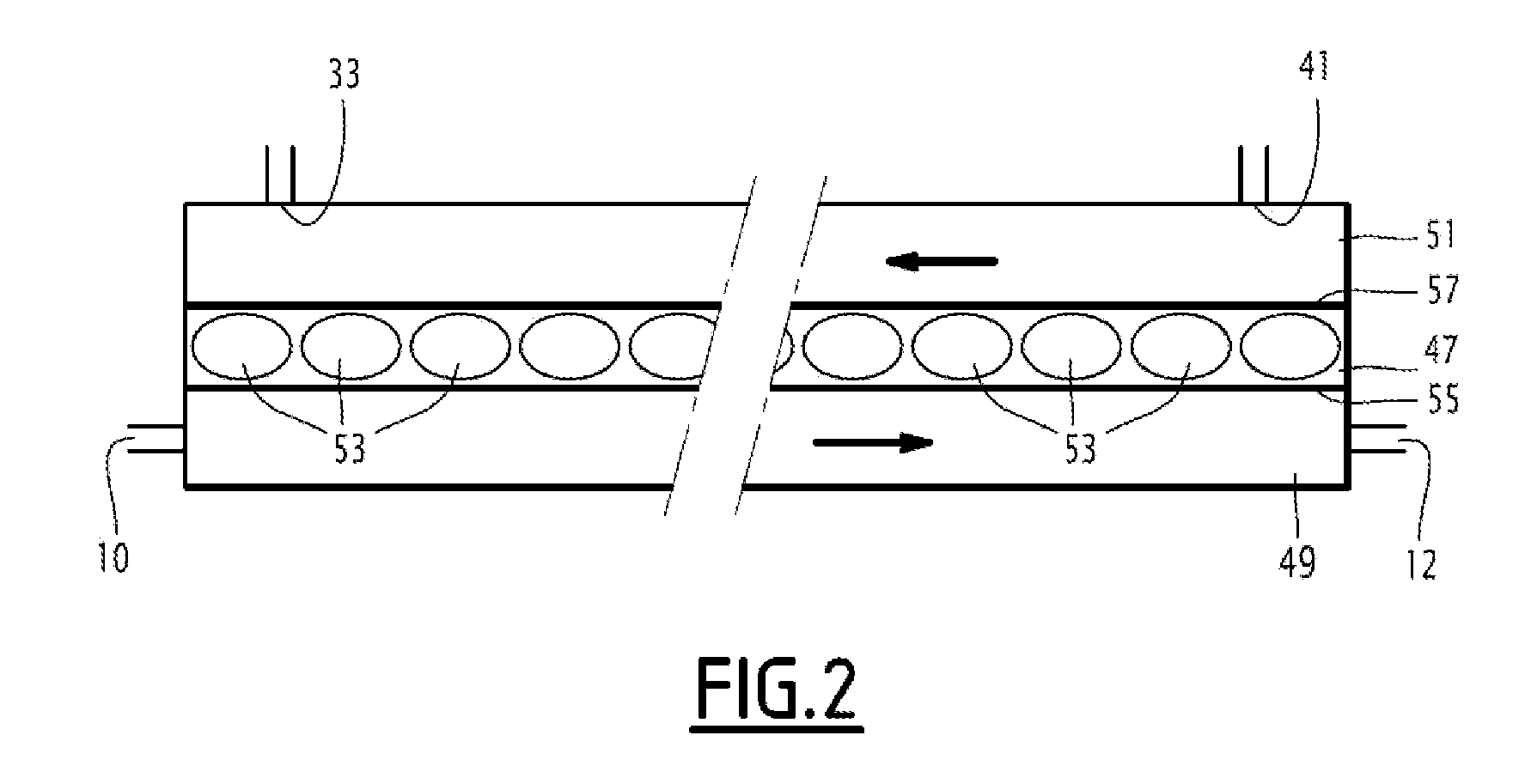

[0042]The exhaust line 1 illustrated in a simplified way in FIG. 1 includes:[0043]a manifold 3 provided for collecting the exhaust gases exiting from the combustion chambers of a heat engine 5 of the motor vehicle;[0044]a heat exchanger 7, having a first side for circulation of the exhaust gases and a second side for circulation of a heat exchange fluid;[0045]an upstream conduit 9 for circulation of the exhaust gases, and which connects the manifold 3 to an inlet 10 on the first side of the heat exchanger 7;[0046]a downstream conduit 11 for circulation of the exhaust gases, and which is connected to an outlet 12 of the first side of the heat exchanger 7;[0047]a bypass conduit 13 that connects a point of the upstream conduit 9 to a point of the downstream conduit 11 by bypassing the heat exchanger 7;[0048]a member 15 for selectively orienting the exhaust gases towards the heat exchanger 7 and / or towards the bypass conduit 13;[0049]a member 17 for controlling the orientation member 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com