Branched Aliphatic-Aromatic Polyester Blends

a polyester blend and aliphatic acid technology, applied in the direction of packaging, synthetic resin layered products, stoppers, etc., can solve the problems of rapid biodegradability, achieve better melt capillary stability, improve thermal stability, and increase melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Reactive Blend composition with PHA, PBAT, Organic Peroxide and Co-agent

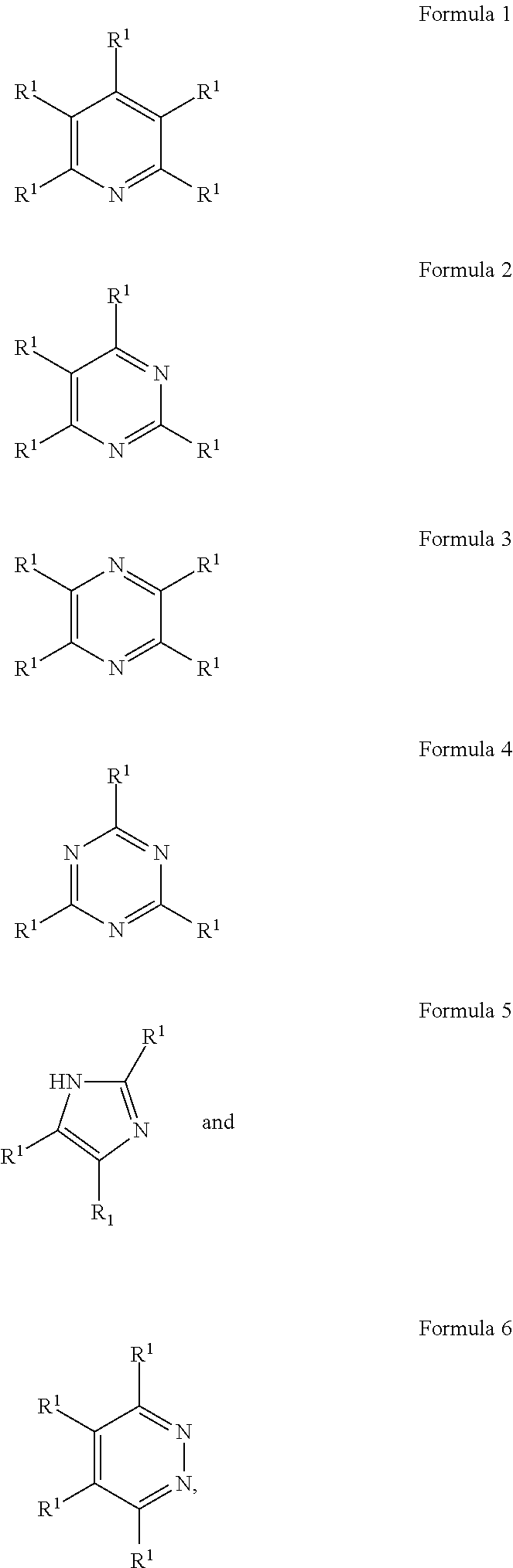

[0147]In this example, rheological data for a PHA reactively melt-compounded with PBAT in the presence of an organic peroxide and co-agent is presented. Other additives included in the formulations were EMFORCE BIO™ calcium carbonate (Specialty Minerals), the plasticizer CITROFLEX™ A4 (Vertellus Specialties Inc.); a Slip / antiblock Master Batch which was a mixture composed of 15% by wt. Erucamide (Croda), 15% by wt. OPTIBLOCTM 10 talc filler (Specialty Minerals); a nucleating agent master batch (Nuc. MB) which was composed of cyanuric acid compounded at 33% by wt. into a base PHA resin of 3-hydroxybutanoic acid and 4-hydroxybutanoic acid and 68% by wt. PHA copolymer blend composed of about 34-38% homo-polymer of 3-hydroxybutanoic acid, and about 22-26% co-polymer of 3-hydroxybutanoic acid and 4-hydroxybutanoic acid, where the 4-hydroxybutanoic acid is approximately 10-12 weight percent, and about 38-42% co-polyme...

example 2

Blown Films Containing Aromatic / Aliphatic Polyester

[0151]In this example, blown films were made and tested for biodegradability. The following PHA formulation was made.

TABLE 3PHA Formulation for Blown FilmIngredientWt %PHA Blend78.00Nuc MB3.00CaCO35.00Slip Antiblock MB5.00CITROFLEX A48.73Peroxide0.18PE3A0.09

[0152]The PHA blend was composed of about 34-38% homo-polymer of 3-hydroxybutanoic acid, and about 22-26% co-polymer of 3-hydroxybutanoic acid and 4-hydroxybutanoic acid, where the 4-hydroxybutanoic acid is approximately 8-14 weight percent, and about 38-42% co-polymer of 3-hydroxybutanoic acid and 4-hydroxybutanoic acid with the 4-hydroxybutanoic acid composition being nominally 25-33 weight percent. The nucleating masterbatch (Nuc. MB) was cyanuric acid that had been previously compounded at a rate of 33% (by weight) into a base resin of 3-hydroxybutanoic acid and 4-hydroxybutanoic acid, and pelleted. The slip anti- block masterbatch was a mixture of erucamide (20% by weight) d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com