Implement attachment having a hydraulically controlled locking function

a technology of hydraulic control and locking function, which is applied in the direction of fluid pressure sealing joints, couplings, basic electric elements, etc., can solve the problems of affecting the safety of drivers, so as to achieve the effect of reducing the risk of locking failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment examples

DESCRIPTION OF EMBODIMENT EXAMPLES OF THE INVENTION

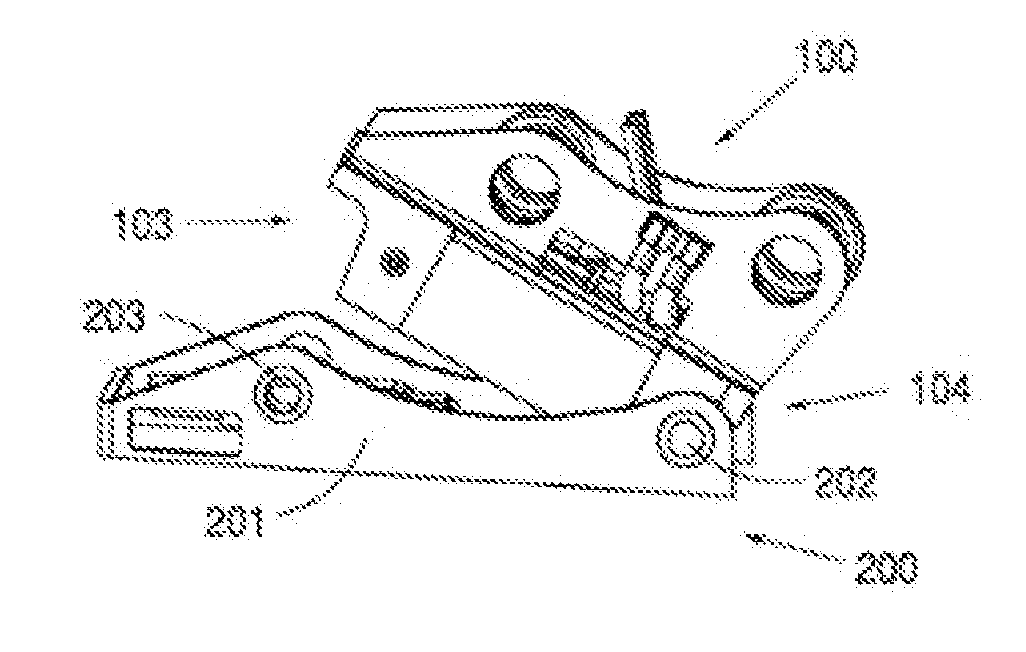

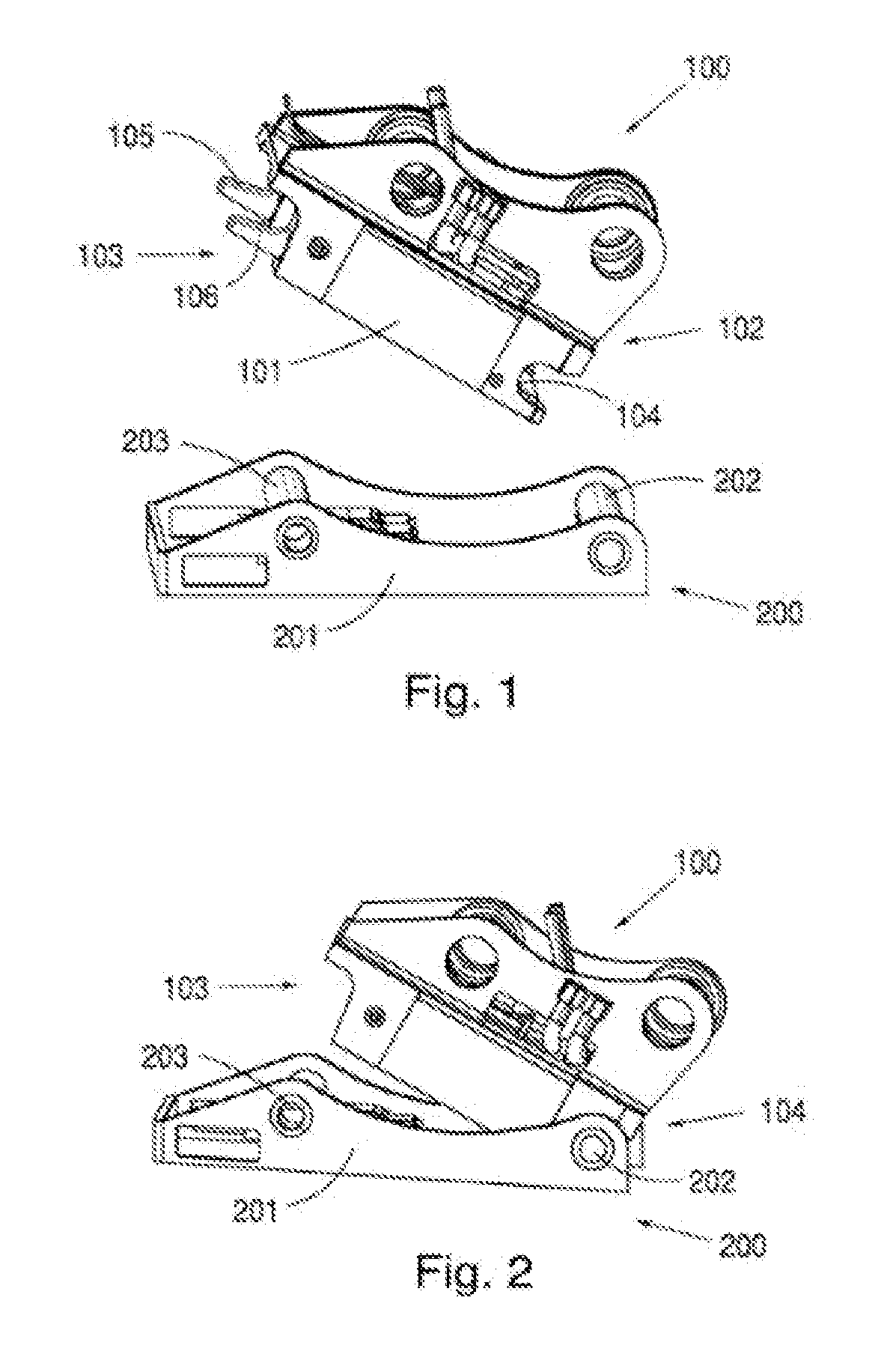

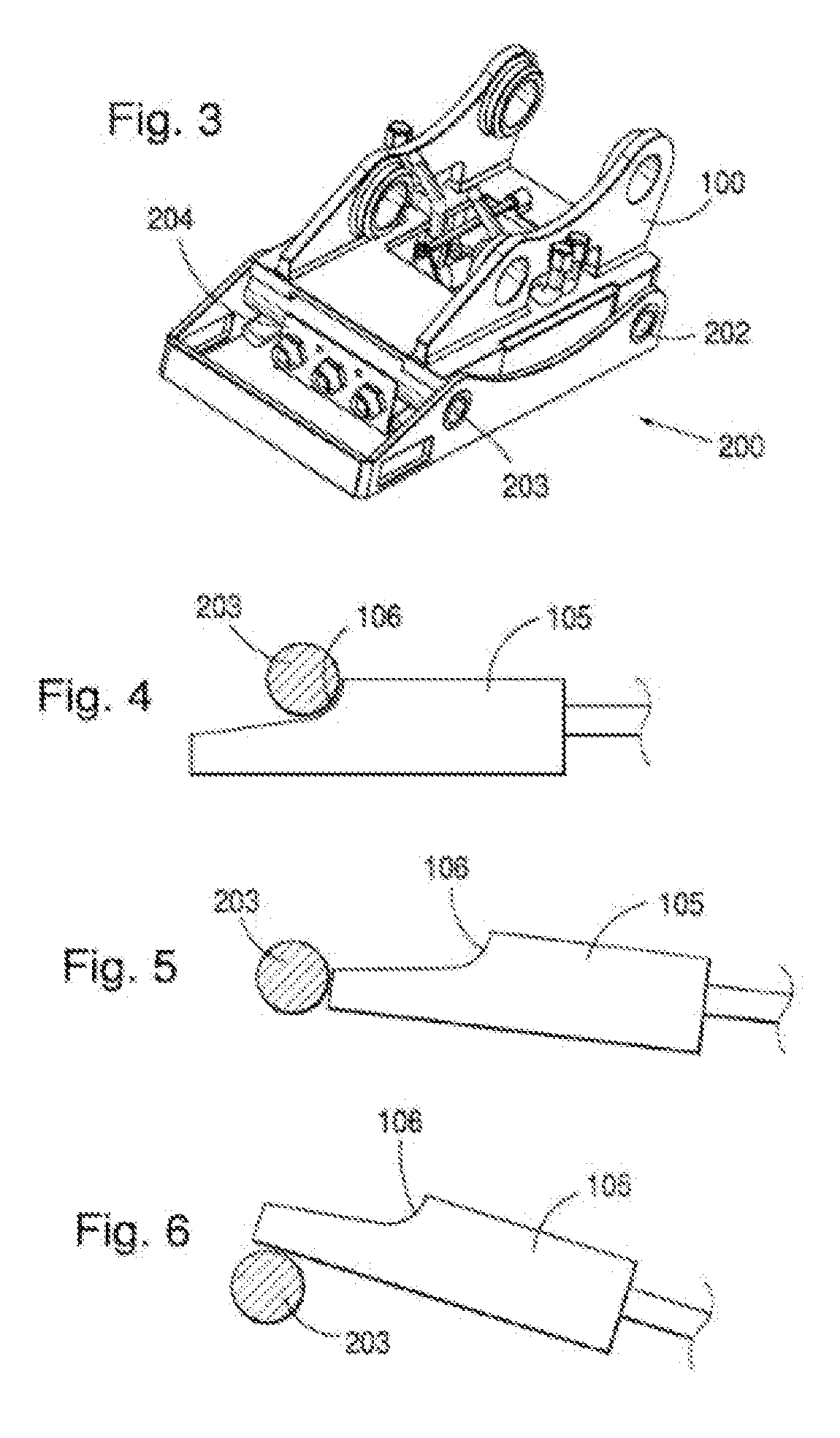

[0057]In FIGS. 1-3, a known system is described for the coupling-together of an implement attachment and a working implement. What is shown in these figures and the description in connection with the same is accordingly comprised in prior art, such as, for instance, is disclosed in EP 602 165 mentioned and that is hereby referred to.

[0058]The system in FIG. 1 consists accordingly of an implement attachment 100 and a working implement 200. The implement attachment 100 is intended to be mounted on a working machine, which however is not shown in the figure. The working implement 200 comprises an implement bracket 201 that is a part that is coupled together with the implement attachment 100 and is of a standardized design for different kinds of working implements. The active part of the working implement is not shown in the figure. This is formed differently for different purposes. By the system, accordingly working implements intended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com