Post anchoring devices and methods

a technology of post anchoring and sleeve, which is applied in the direction of building components, building repairs, foundation engineering, etc., can solve the problems of unsightly supporting triangular brackets, superior aesthetic solutions designed to conceal fasteners, and previously possessed lower strength characteristics, so as to improve performance, reduce hardware requirements and the time to install the device using this method, the effect of boosting performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063]Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. The invention disclosed herein may be practiced in embodiments in many different forms. Shown in the drawings and described herein are preferred embodiments of the present invention. However, it is understood that the present disclosure is an exemplification of the principles of the invention and does not limit the invention to the illustrated embodiments.

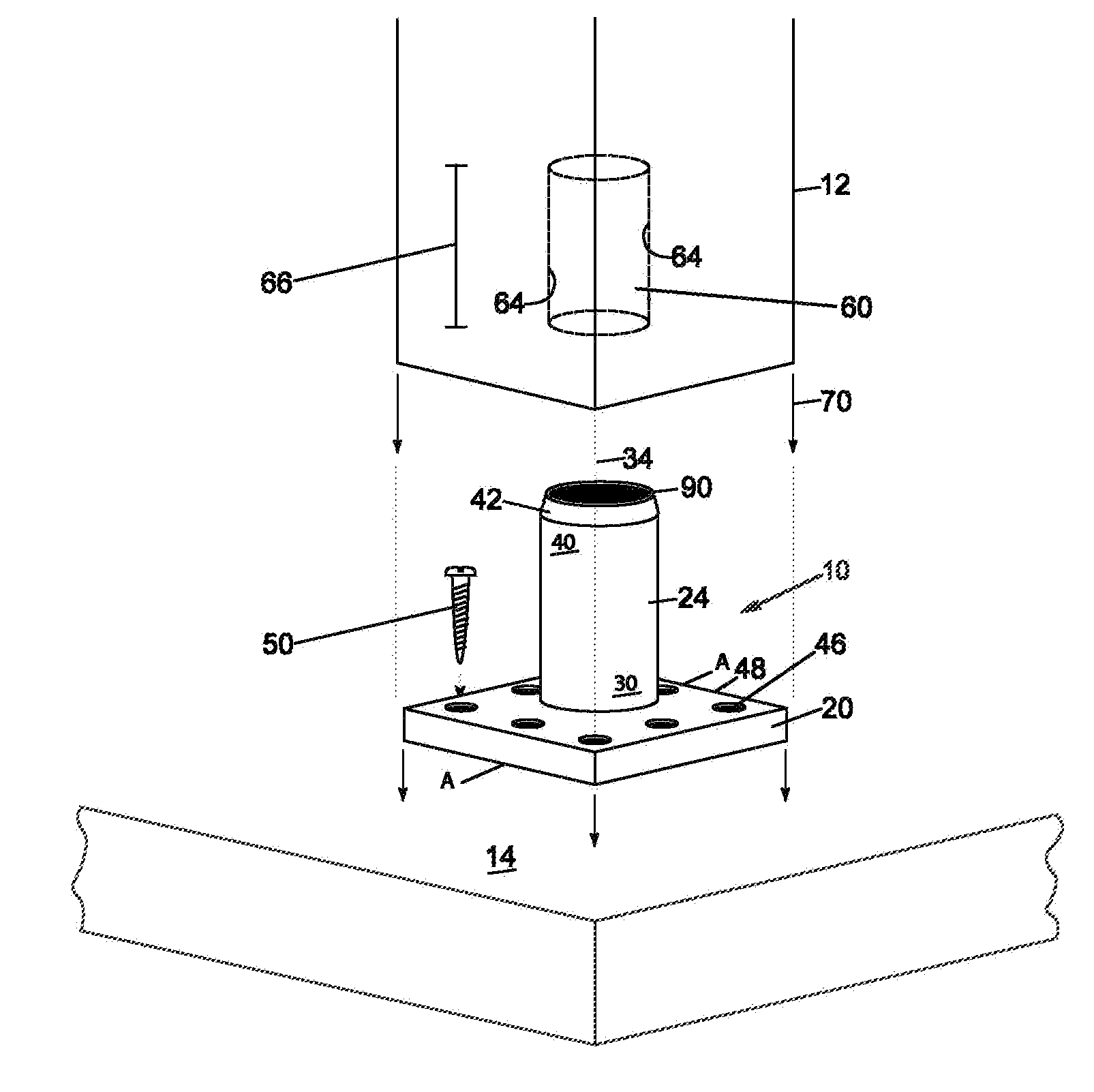

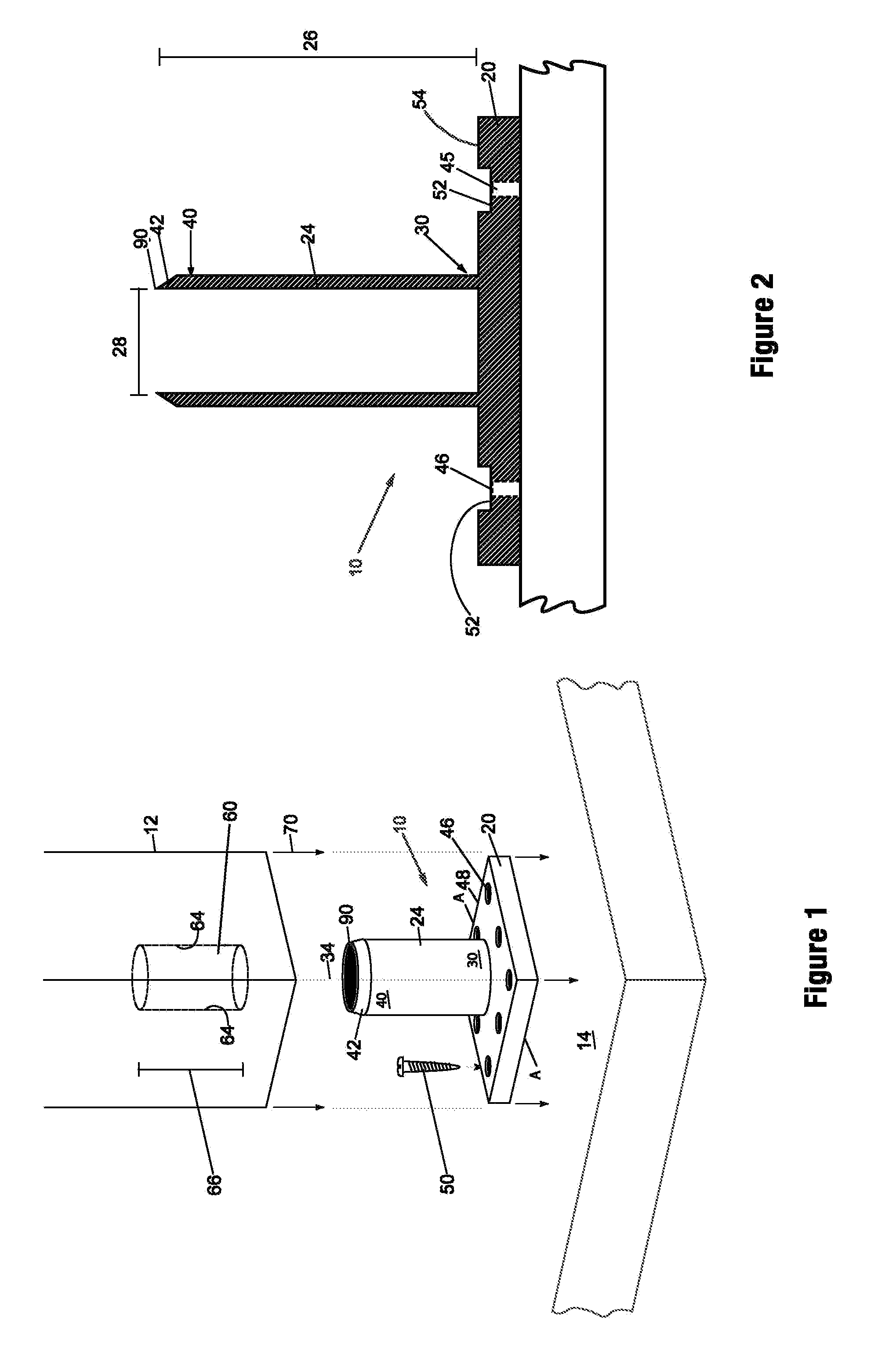

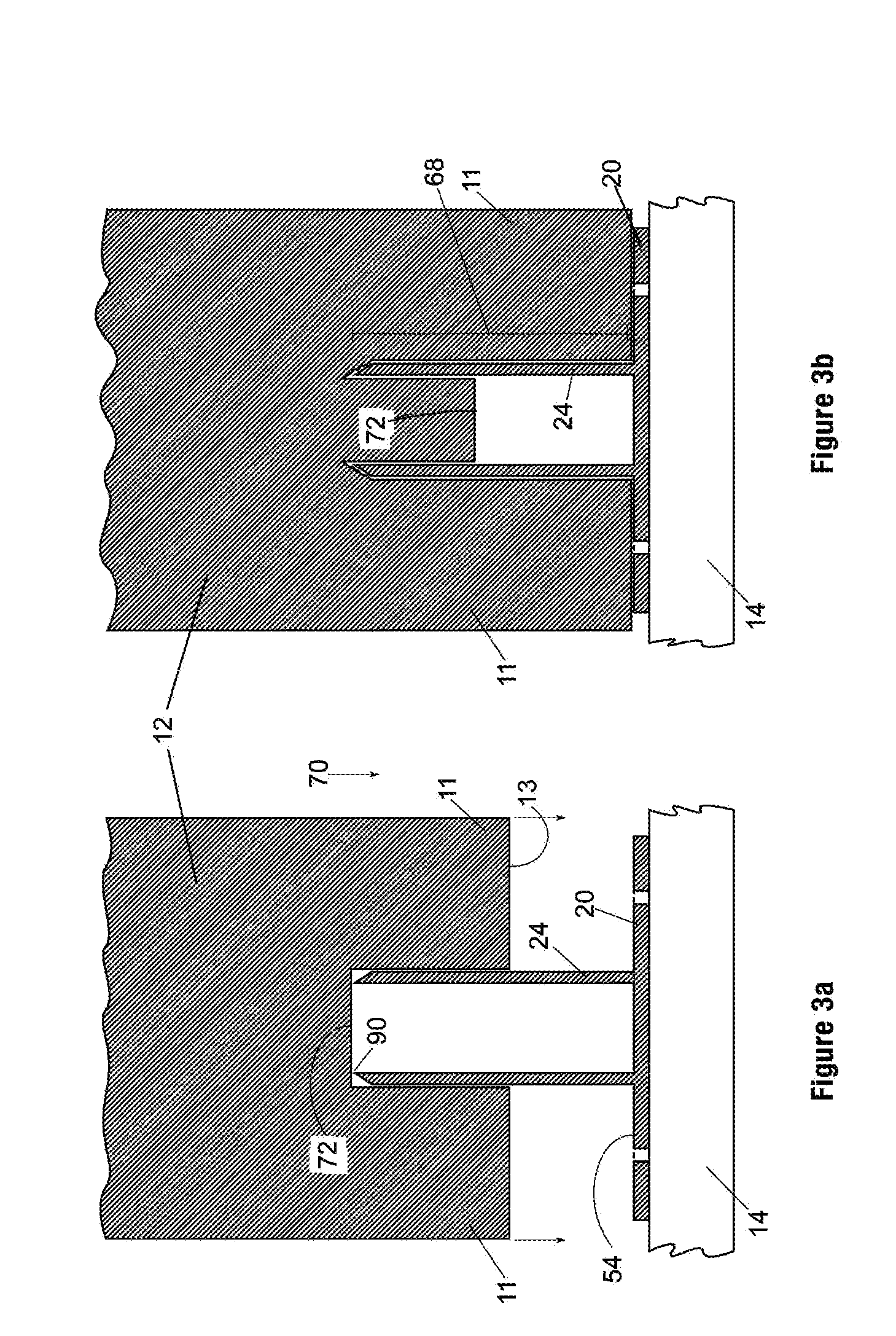

[0064]Referring to FIGS. 1-3, there is depicted an embodiment of the present invention: a post anchoring device 10 for anchoring a post 12 to a surface 14. Device 10 comprises a planar base member 20 and an elongate tubular member 24 that is preferably cylindrical. As used herein, the word “tubular” means having the form or shape of a thin-walled hollow body. The tubular member is connected at a base end 30 to the base member. Preferably, longitudinal axis 34 of the tubula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com