Three-dimensional coherent plasmonic nanowire arrays for enhancement of optical processes

a plasmonic nanowire array and optical process technology, applied in the field of enhancement of optical processes, can solve the problems of reduced efficiency of collection aspect of any probing system, low uniformity and reproducibility on a large-area substrate, and process typically too weak to d

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

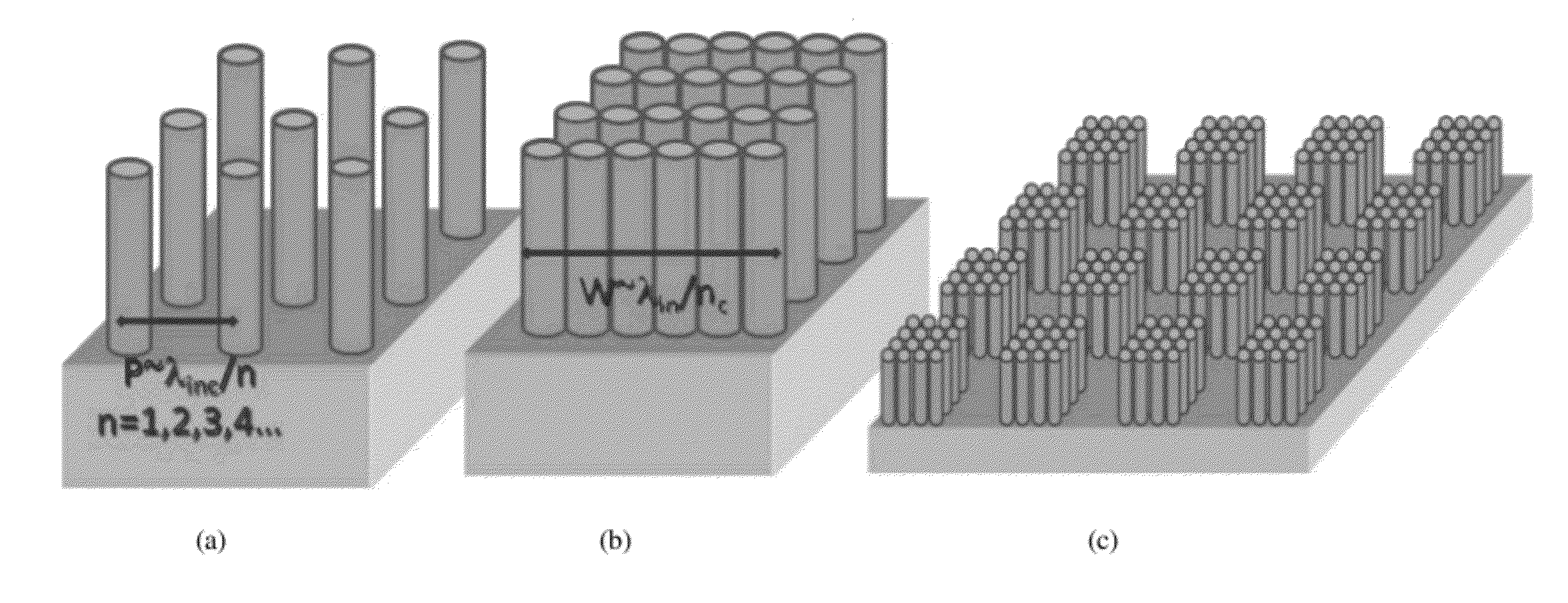

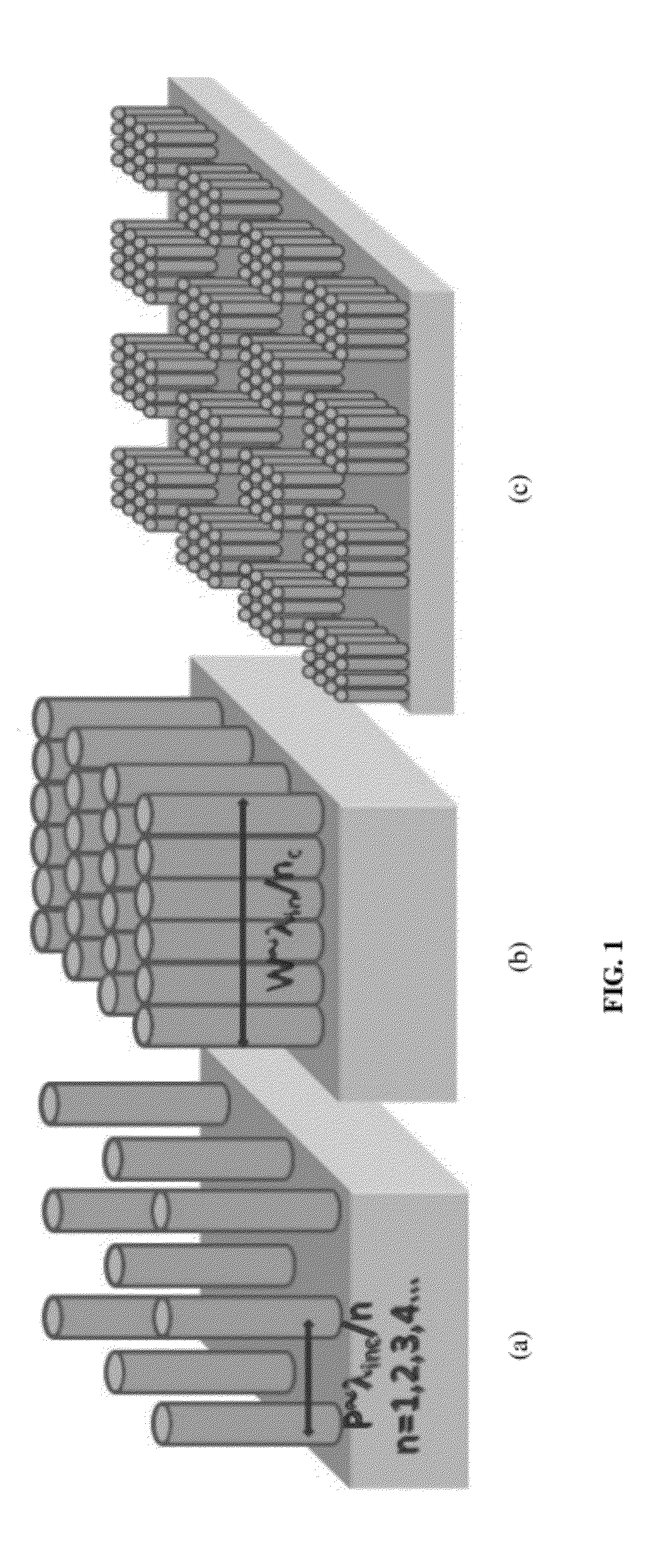

[0018]The present invention pertains to three arrayed plasmonic architectures that solve the need for a large area sensor with high signal uniformity and reproducibility, while maintaining high average SERS enhancement factors. The first structure is the plasmonic-grating sensor, which comprises periodic arrays of plasmonic nanoparticles with the interparticle pitch being on the order of a wavelength of light within the medium (λ / neff; neff is the effective index of refraction for the material chosen) in the UV-Vis-NIR region of the electromagnetic spectrum (200-2000 nm). The second structure is the coupled-plasmonic array sensor, which comprises periodic arrays of plasmonically coupled nanopillars / nanowires with interparticle gaps small enough to enable overlap between the evanescent fields from neighboring plasmonic nanoparticles, which typically requires edge-to-edge separations between the nanoparticles of less than 20 nm The third structure is the plasmo-photonic array sensor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com