Variable valve timing control apparatus of internal combustion engine

a technology of timing control apparatus and internal combustion engine, which is applied in mechanical equipment, valve arrangements, machines/engines, etc., can solve the problems of increasing the thickness of the shoe, increasing the relative rotational angle between the housing and the vane, and reducing the strength of the shoe, so as to reduce the hydraulic pressure and increase the number of vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

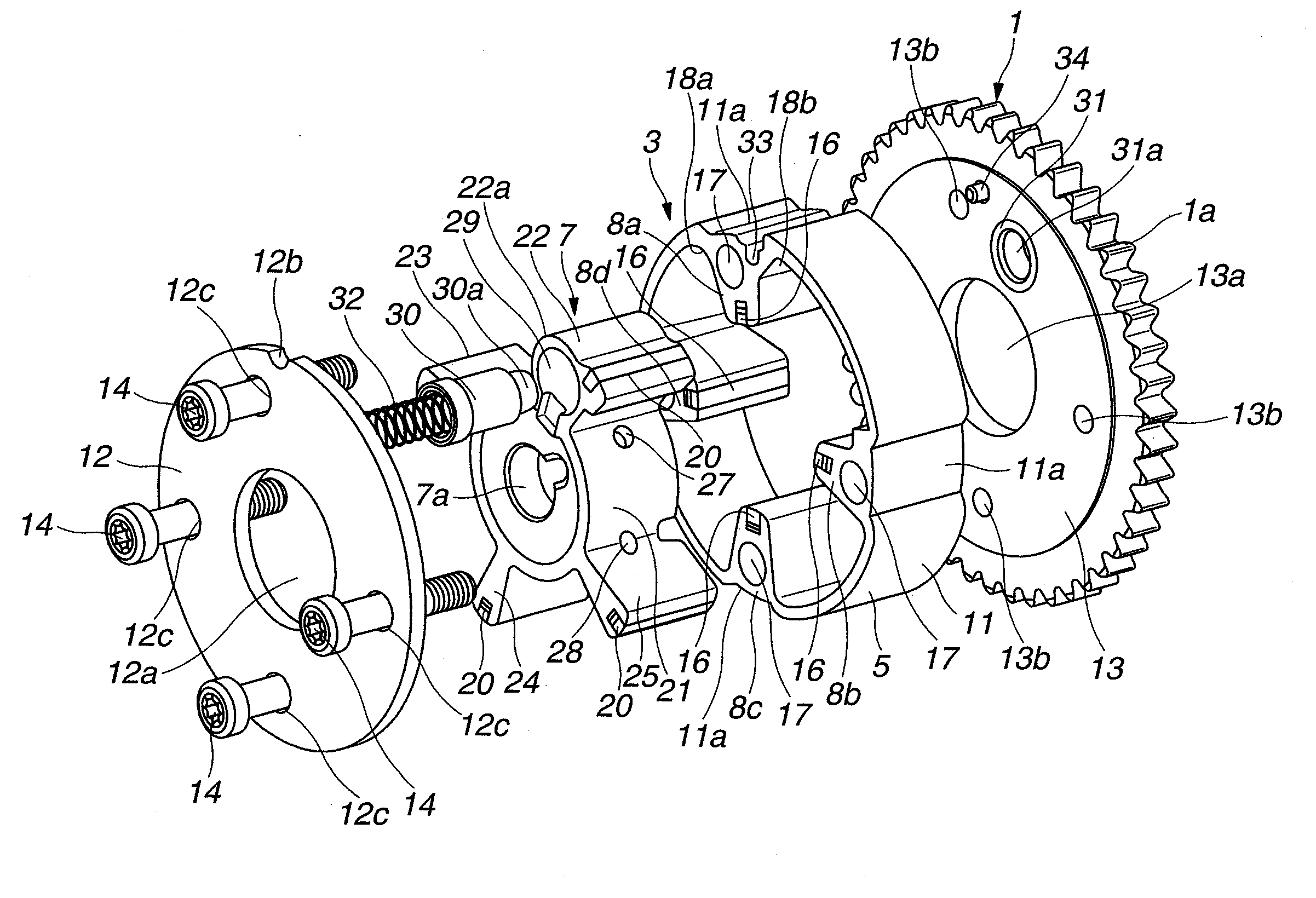

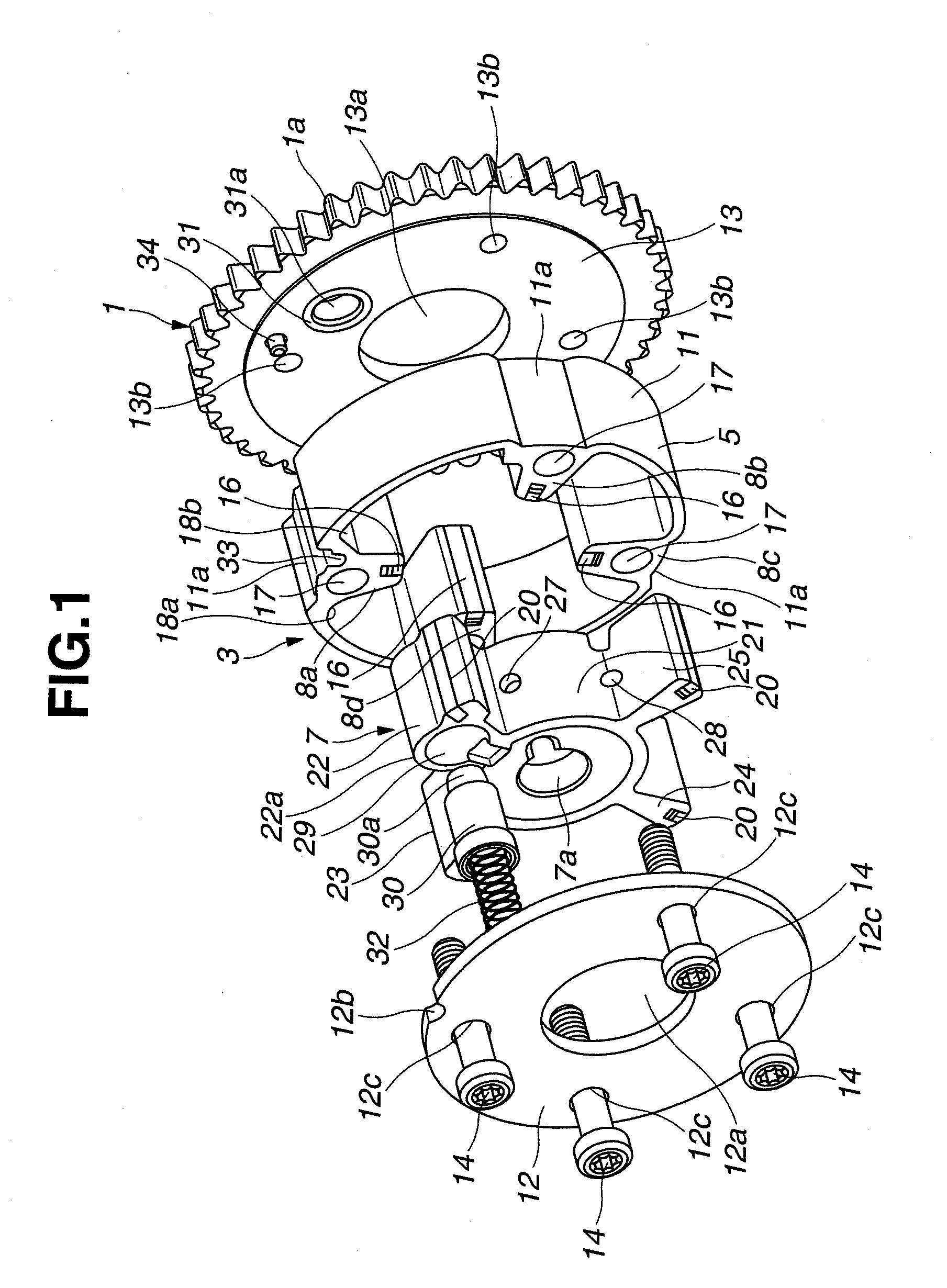

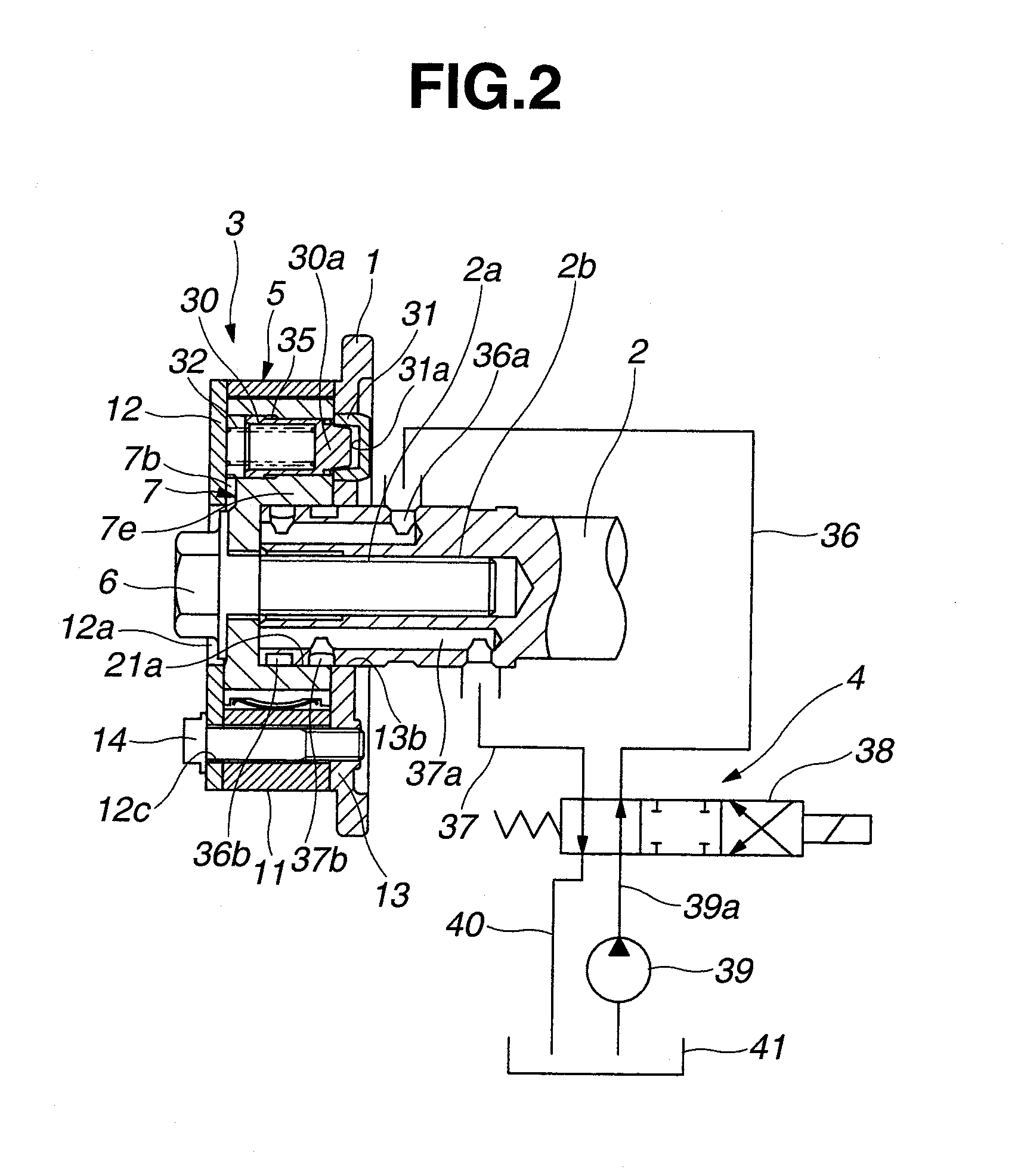

[0022]FIGS. 1 to 5 show a first embodiment of the variable valve timing control apparatus. The variable valve timing control apparatus has a sprocket 1 that is driven and rotates by an engine crankshaft (not shown) through a timing chain, a camshaft 2 that is capable of rotating relative to the sprocket 1, a relative angular phase control mechanism (simply, a phase converter or a phase-change mechanism) 3 disposed between the sprocket 1 and the camshaft 2 and changing or controlling a relative rotational position between the sprocket 1 and the camshaft 2, and a hydraulic circuit 4 that actuates the phase-change mechanism 3.

[0023]The camshaft 2 is rotatably supported by a cylinder head (not shown) through a camshaft bearing. The camshaft 2 has a plurality of driving cams, each of which actuates an intake valve through a valve lifter. Each driving cam is formed integrally with the camshaft 2 at a certain position on an outer peripheral surface of the camshaft 2. Further, the camshaft ...

second embodiment

[0082]FIGS. 6 and 7 show a second embodiment of the variable valve timing control apparatus. A basic structure is the same as that of the first embodiment. However, in the second embodiment, the relative rotational position of the most-advanced angle side of the vane member 7 is limited by the fact that, as shown in FIG. 7, the narrow second vane 23, which is adjacent to the first vane 22 in the counterclockwise direction, touches a side surface at the thick portion 18a side of the first shoe 8a when the vane member 7 rotates to the maximum to the most-advanced angle side (i.e. in the clockwise direction) with respect to the housing 5.

[0083]That is, as same as the first embodiment, the first shoe 8a is provided with the first thick portion 18a and the thick part 18b at the both corners of the first shoe 8a.

[0084]On the other hand, as for the second vane 23, a protruding portion 62 is formed integrally with a base portion side surface, at the first shoe 8a side, of the second vane 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com