Shots made from zinc-based alloy

a zinc-based alloy and alloy technology, applied in the field of shots, can solve the problems of easy burst, insufficient grinding and cleaning ability, cloud of dust, etc., and achieve the effect of high concentration, easy burst, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

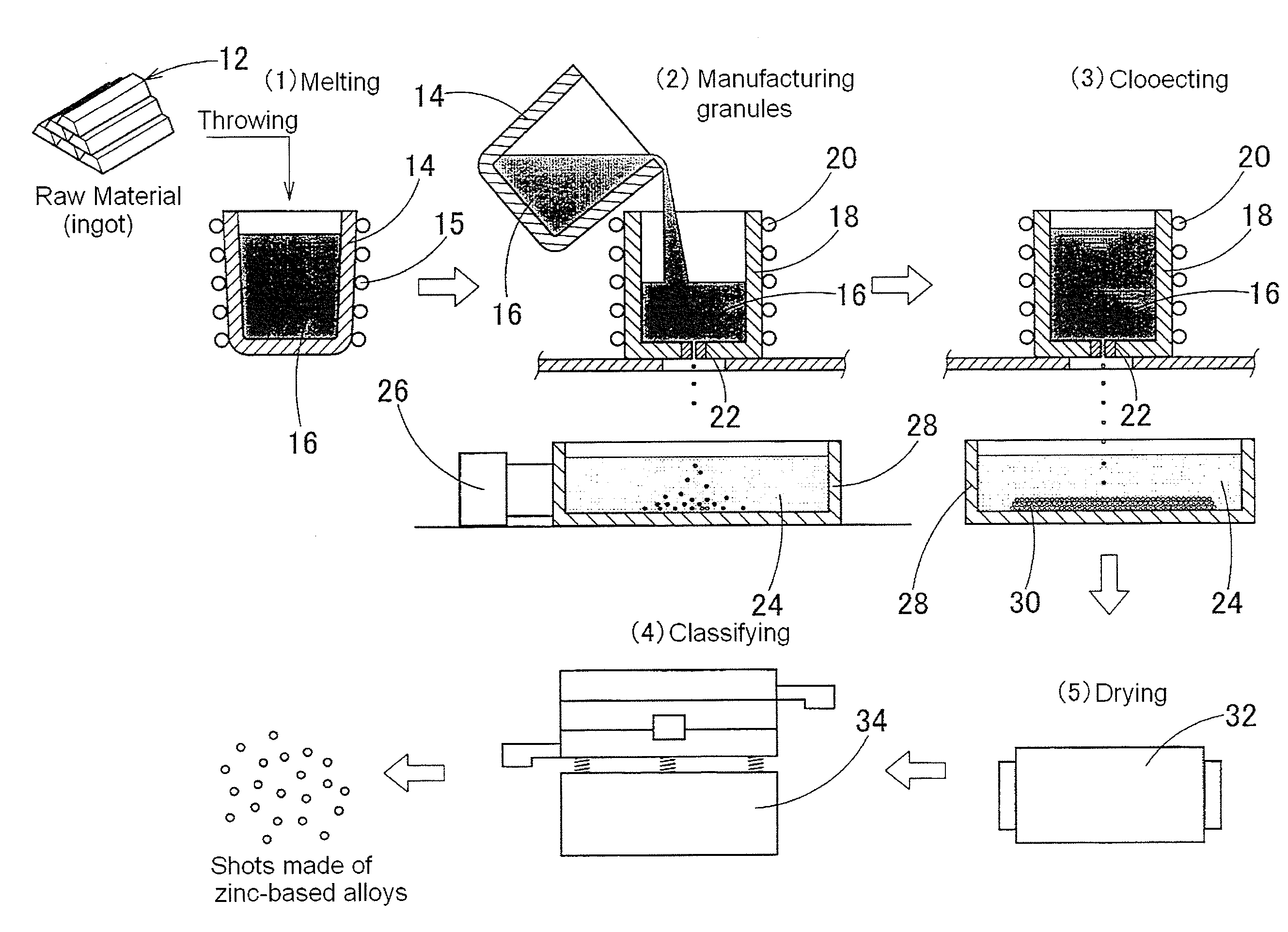

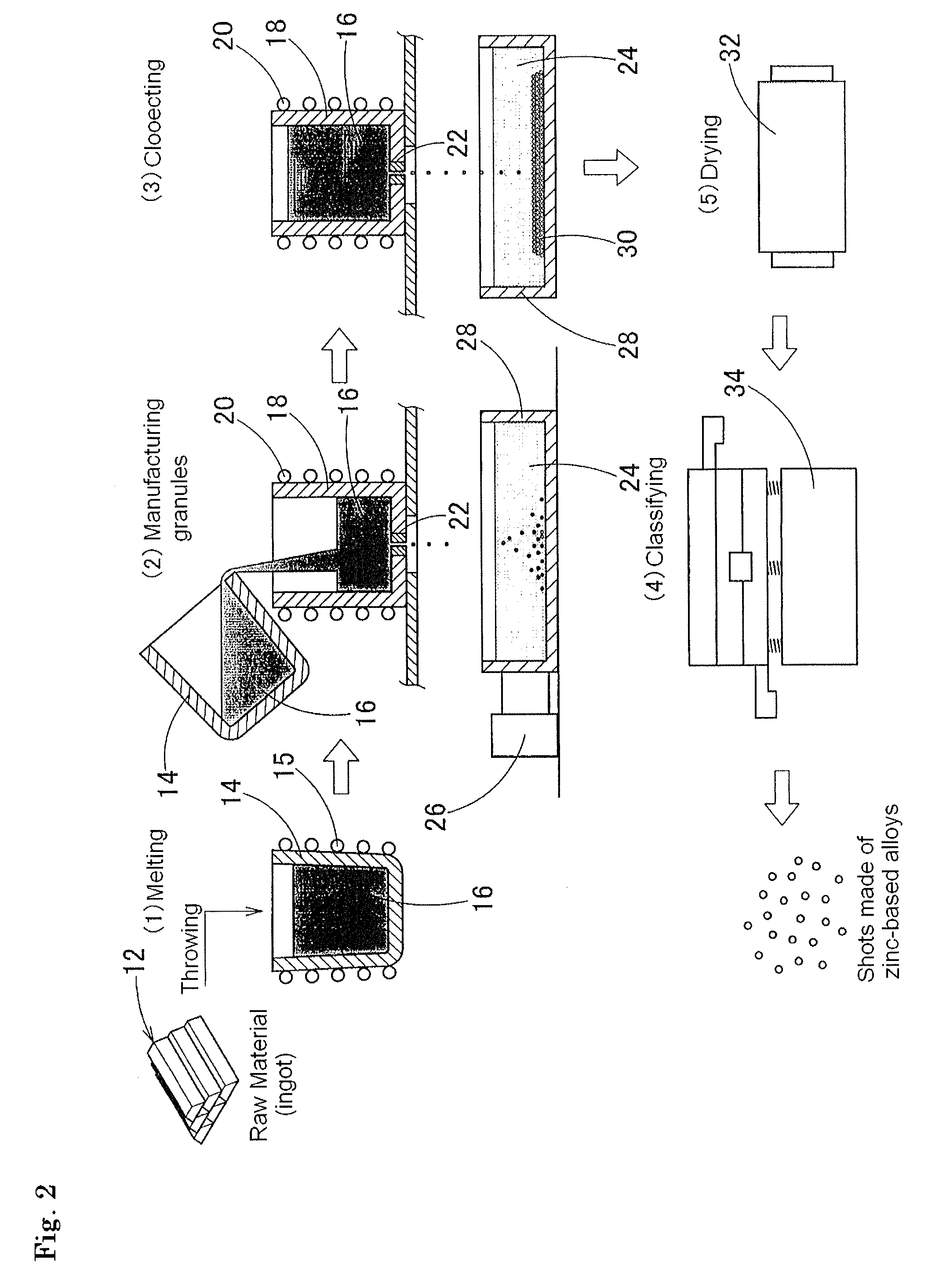

Method used

Image

Examples

working examples

[0062]Below, the working examples are described with comparative examples to verify the effects of the first and second inventions.

[0063]Working Examples 1-1 to 1-8 and Comparative Examples 1-1 to 1-6 correspond to the first invention. Working Examples 2-1 to 2-3 and Comparative Examples 2-1 to 2-3 correspond to the second invention.

[0064]The raw materials for each element for the alloys are the following ingots. The purities (the lower limits) of each ingot for the alloys that are specified by JIS are shown with their amounts of Fe (allowable maximum contents). Here, the Fe amount of the “first class recycle material of copper wires” is an estimated value.

[0065]The total amount of raw materials of the elements for the alloy: 200 kg

[0066]Used Ingot A (for working and comparative examples except for Working Examples 1-6 and 2-3)[0067]Zn: a normal zinc ingot (JIS H 2107) 99.97%; Fe: 0.01%[0068]Al: a third class aluminum ingot (JIS H 2102) 99.00%; Fe: 0.80%[0069]Cu: a first class recyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean diameter | aaaaa | aaaaa |

| mean diameter | aaaaa | aaaaa |

| mean diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com