Method and device for high-temperature combustion using fuel and aqueous solution of organic compound

a technology of organic compound and combustion method, which is applied in the direction of combustion types, lighting and heating apparatus, incinerator apparatus, etc., can solve the problem of difficult to expect a significant increase in combustion efficiency, and achieve the effect of reducing the cost of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

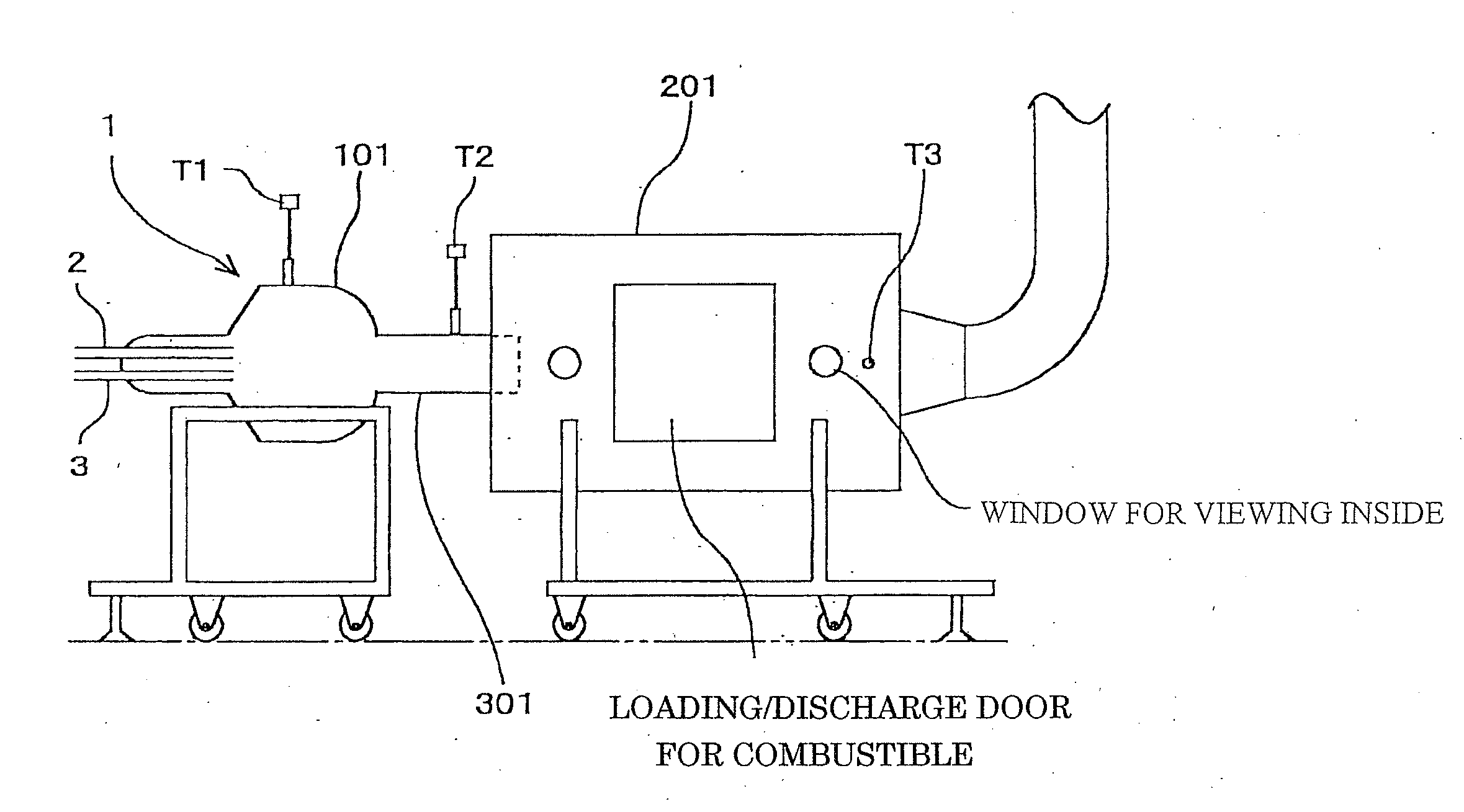

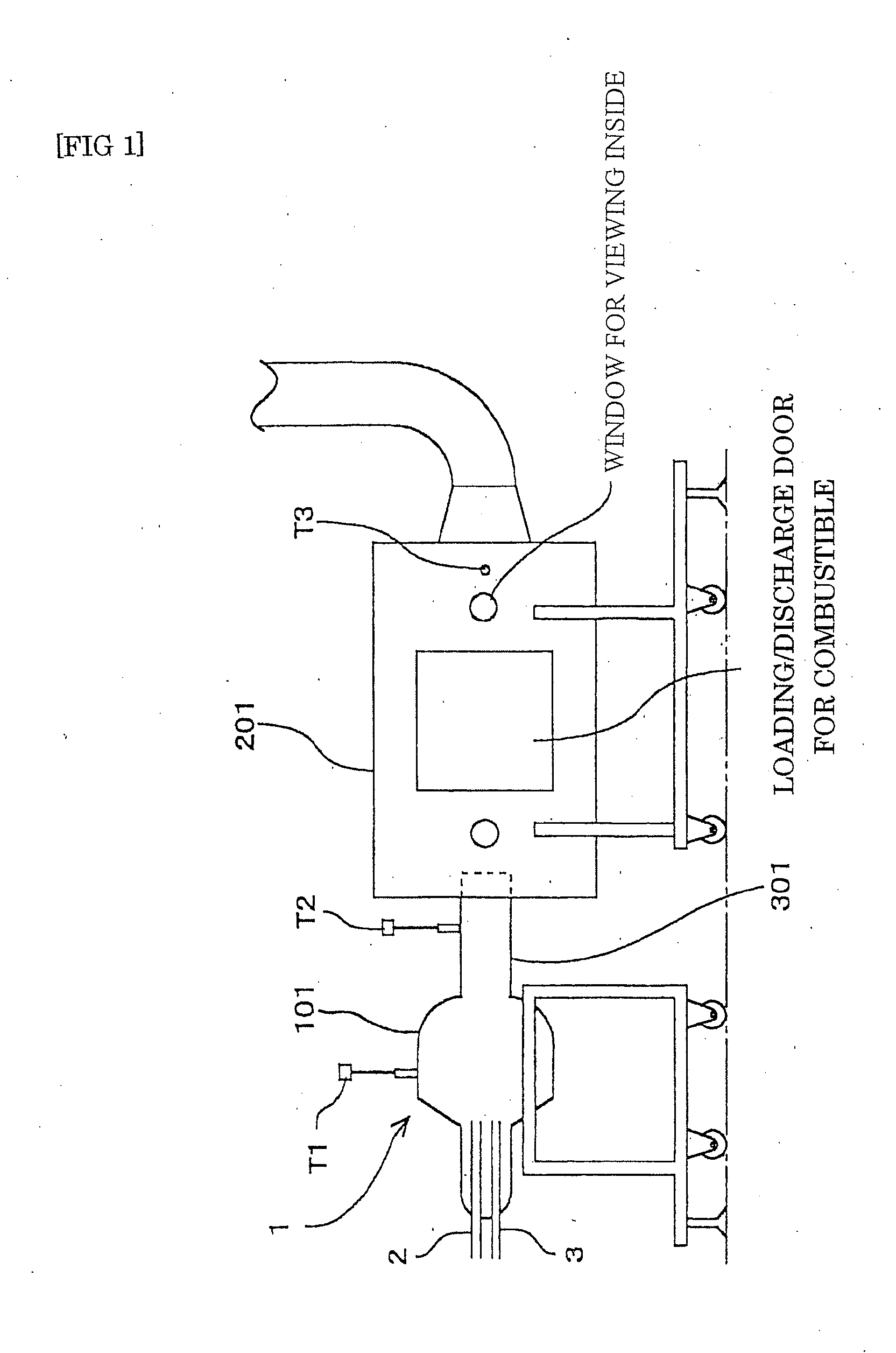

[0043]In this example, a device having a combustion chamber 1 to which a chamber for heat treatment 201 is connected is used as illustrated in the frontal view of FIG. 1.

[0044]Specifically, the combustion chamber 1 and the chamber for heat treatment 201 are connected to each other via a pathway 301 with reduced diameter, which connects an exit of the combustion chamber 1 and an entrance of the chamber for heat treatment 201.

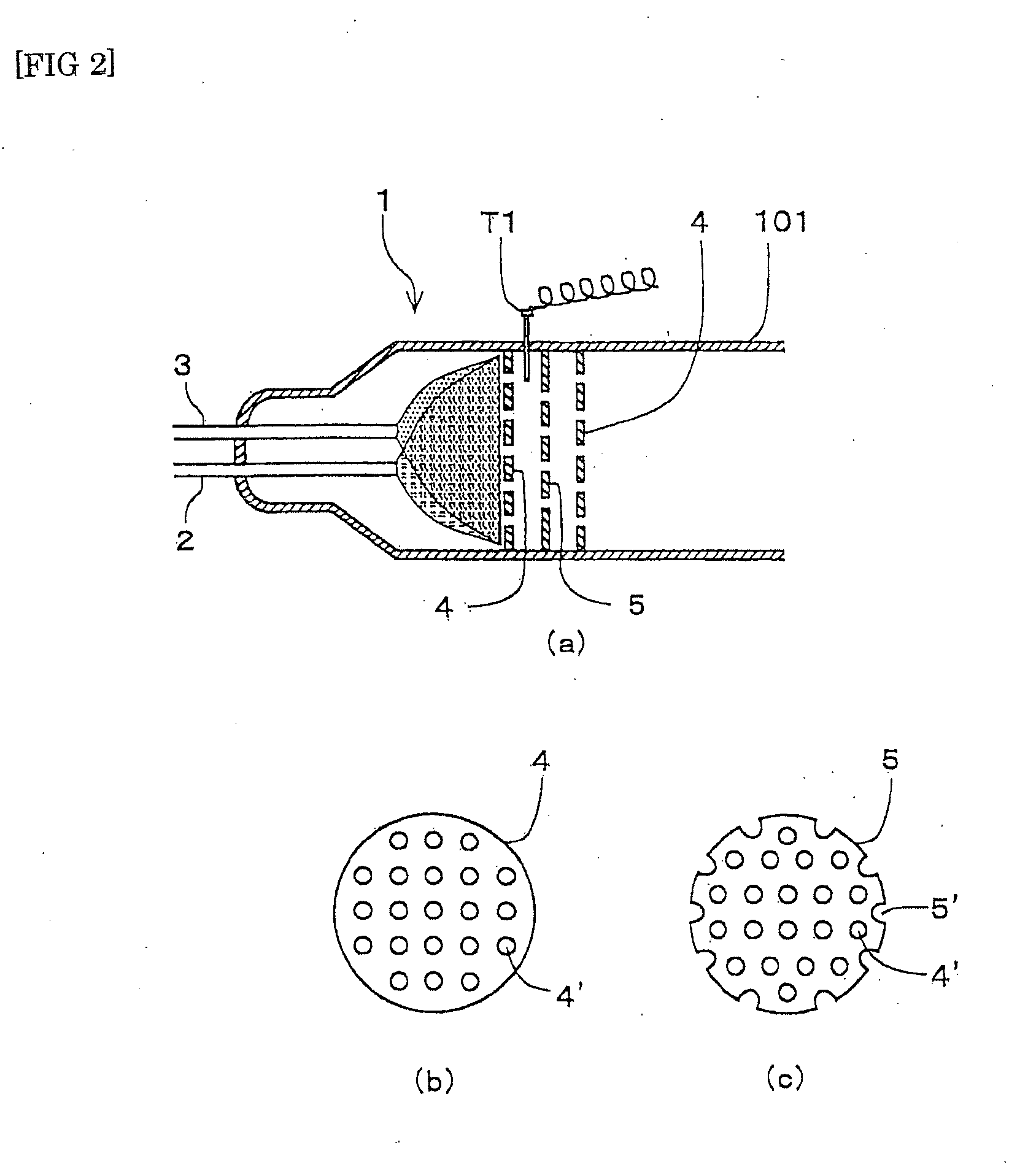

[0045]Further, in the combustion chamber 1, a first burner 2 for elevating the interior temperature to a high temperature of 700° C. or above and a second burner 3 for spraying an aqueous solution of an organic compound are installed.

[0046]Further, thermometers are placed at three spots in the device, that is, a first thermometer T1 is placed in the combustion chamber 1, a second thermometer T2 is placed in the pathway 301, and a third thermometer T3 is placed in the chamber for heat treatment 201.

[0047]Meanwhile, the chamber for heat treatment 201 is a place for...

example 2

[0057]Next, another example is explained.

[0058]First, heavy oil A was sprayed at 6.6 L / H (5.7 kg / H) from a first burner 2 to heat a combustion chamber 1. After heating for about one hour, temperature of a chamber for heat treatment 201 was 630° C. as measured by T3.

[0059]When 30% by volume aqueous ethanol solution (ethanol 4.6 L+water 10.6 L) was sprayed at 15.2 L / H by using a second burner 3, temperature of the chamber for heat treatment 201 as measured by T3 showed an increase of 190° C. from 630° C. to 820° C.

[0060]For the comparison, instead of 30% by volume aqueous ethanol solution, the same amount of pure ethanol was added and sprayed at 4.6 L / H by using the second burner 3, and as a result, temperature of the chamber for heat treatment 201 showed an increase of only 130° C., i.e., from 630° C. to 760° C.

[0061]The results are illustrated in FIG. 4.

[0062]Since the chamber for heat treatment 201 is used as a heating device for actual industrial use, the temperature increase in t...

example 3

[0069]The test was carried out in the same manner as Example 2 for 30% by volume aqueous methanol solution and pure methanol in the same amount.

[0070]The results are illustrated in FIG. 6.

[0071]By using the device illustrated in FIG. 1, heavy oil A was sprayed at 6.6 L / H from a first burner 2 into a combustion chamber 1 and heated. After heating for 1 hour, a thermometer T2 in the pathway connecting the exit of a combustion chamber reached 800° C. and exhibited an almost stable state. Thus, 30% by volume aqueous methanol solution was sprayed at 15.2 L / H (pure methanol 4.6 L / H and water 10.6 L / H) from a second burner 3. After 20 minutes, the thermometer T2 in the pathway connecting the exit of a combustion chamber showed 940° C., indicating a temperature increase of 140° C. while a thermometer T3 in a chamber for heat treatment showed a temperature increase of 130° C., i.e., from 630° C. to 760° C.

[0072]Meanwhile, for the comparison, pure methanol was sprayed at 4.6 L / H by using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com