Dual-flow-baffle compound gasoline fractionator of ethylene unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Further description is made below to the invention with reference to the embodiments and the drawings thereof.

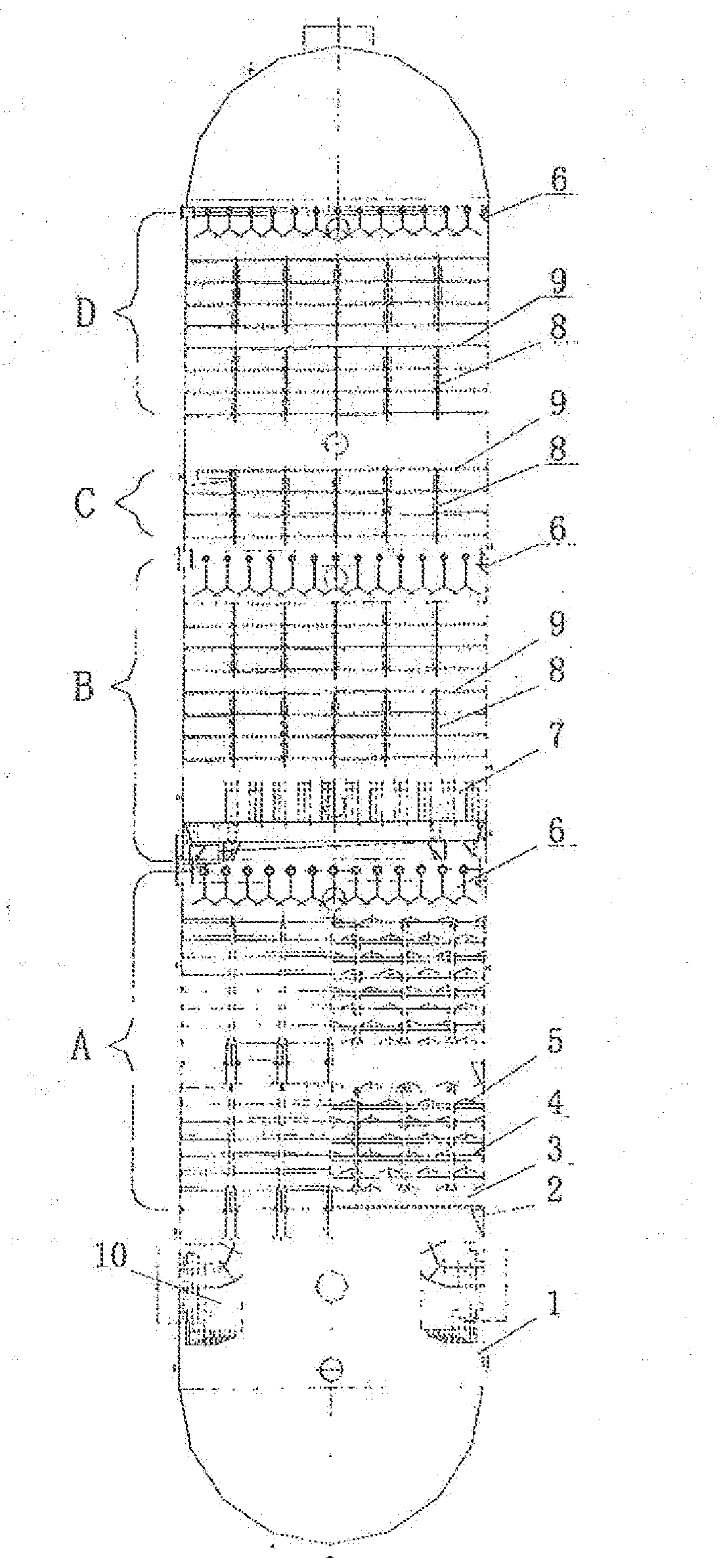

[0036]Shown as FIG. 1, the gasoline fractionator of ethylene unit comprises a tower body I as well as an orifice and instruments thereof (not shown), the functional sections of the tower body sequentially are a quench oil circulation section A, a medium oil circulation section 8, a diesel oil separation section C and a petroleum separation section D in an ascending direction.

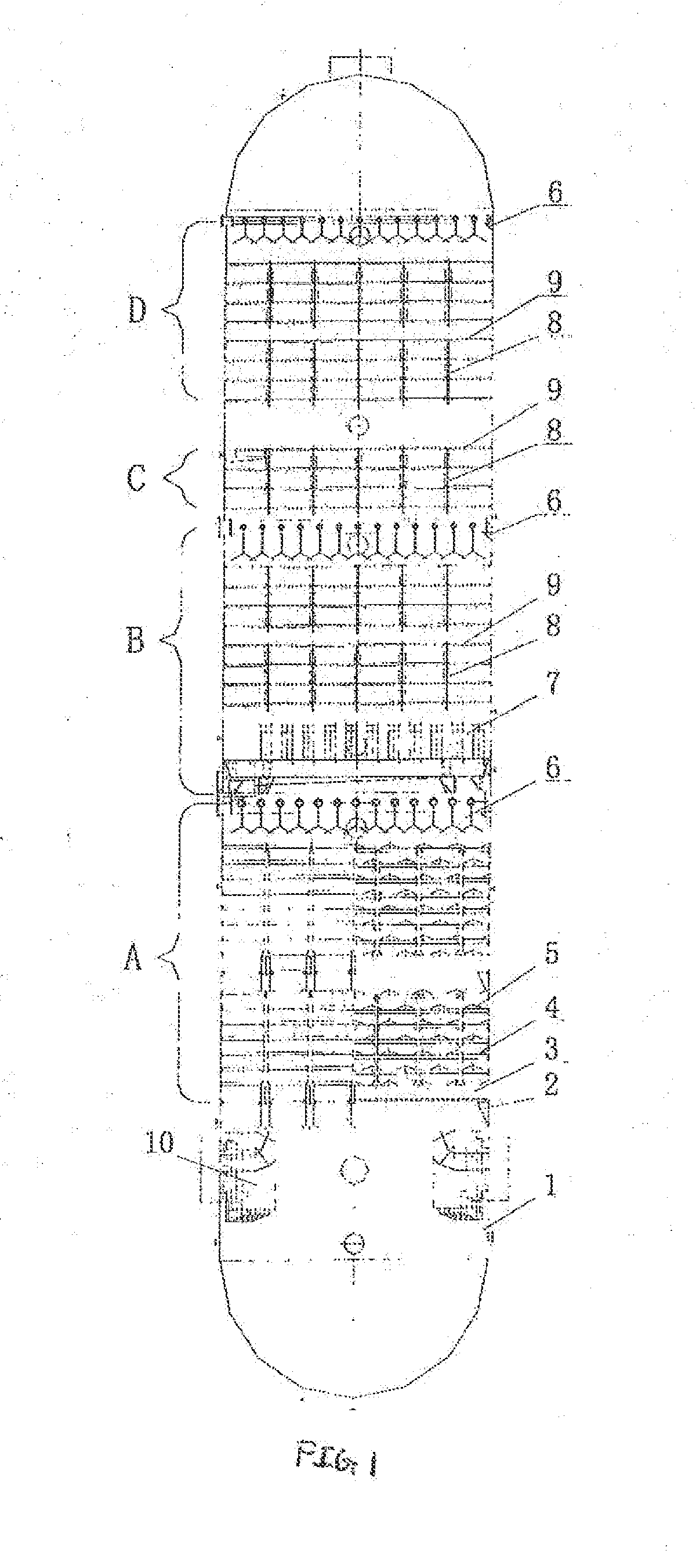

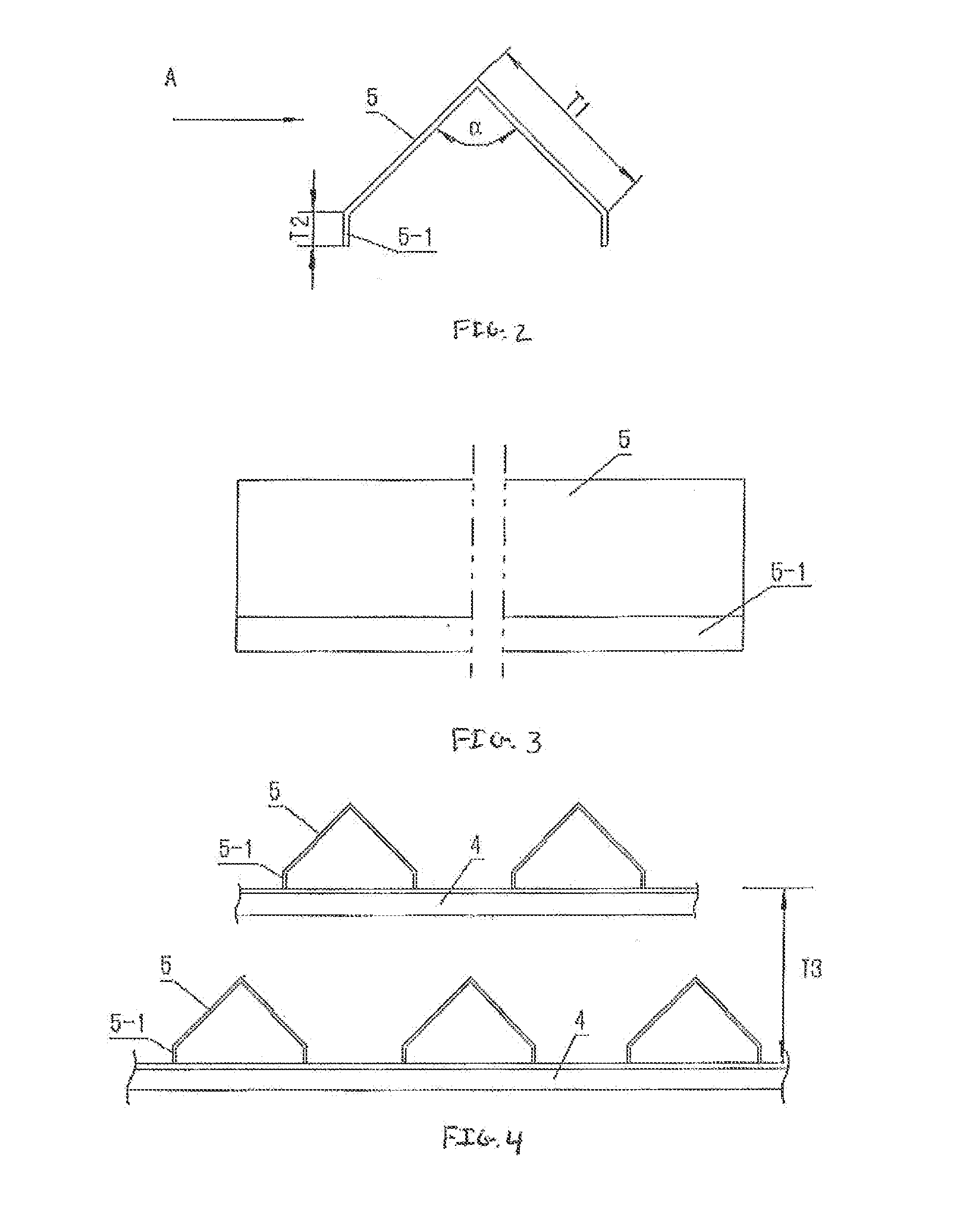

[0037]10 to 16 layers of micro baffles 5 are arranged between nozzle-type liquid distributors 6 and three-dimensional compound guide-type inlet initial distributors 10 of the quench oil circulation section A, and in the embodiment shown as FIG. 1, 15 layers of the micro baffles 5 are arranged and supported by a space truss 4, and structural description is made below to the micro baffles 5 and the space truss 4 respectively.

[0038]Shown as FIG. 2, 3, a vertex angle α of the micro baffle 5 of the quen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com